TPO Geomembrane HDPE Pond Liners HDPE Geomembrane Smooth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geomembrane

1.Gas Defence fish pool liner vinyl pool liners

2.1m-8m width

3.0.2mm-3.0mm thickness

Geomembrane specifications

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

HDPE geomenbrane Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

HDPE Geomembrane Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

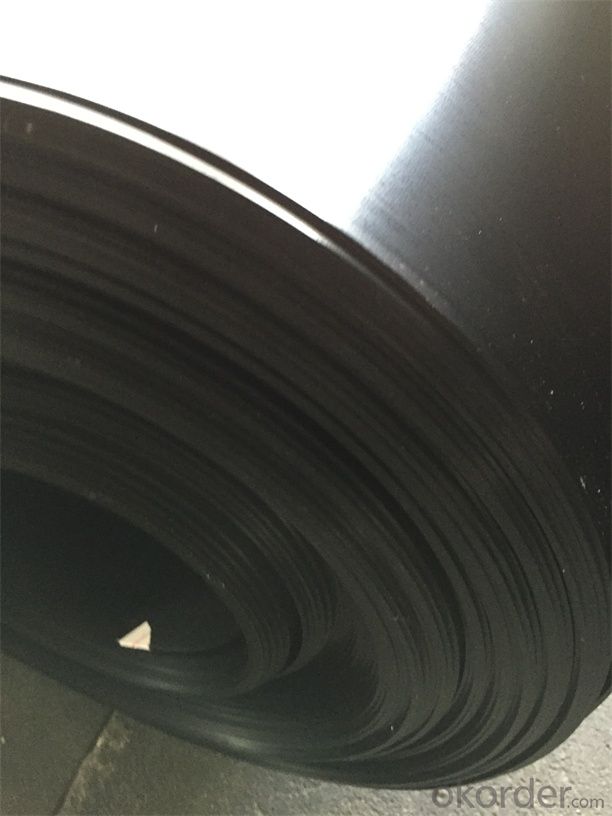

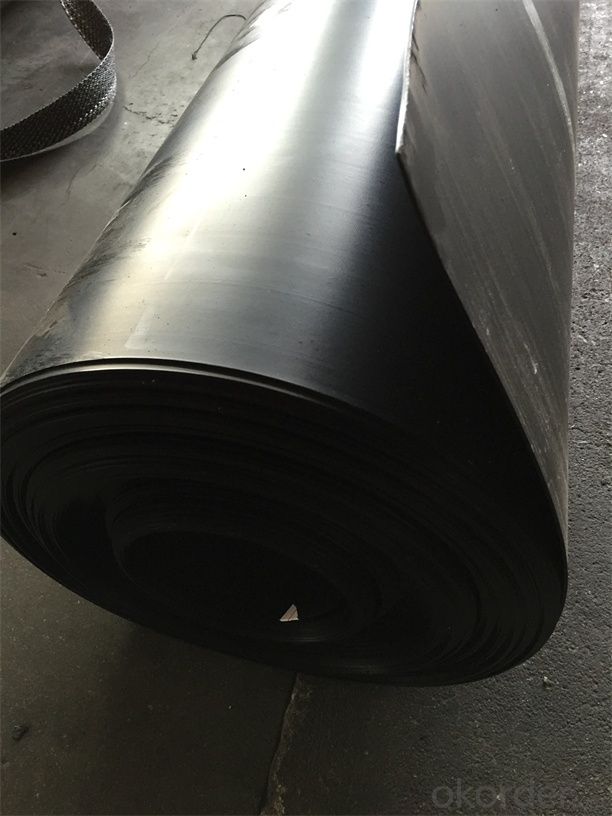

Gemembrane Show:

- Q: Can geomembranes be used for lining tunnels?

- Yes, geomembranes can be used for lining tunnels. Geomembranes are flexible, durable, and impermeable materials that can effectively prevent water leakage and protect the tunnel structure. They are commonly used in tunnel construction to provide a robust barrier against groundwater and ensure the long-term integrity of the tunnel.

- Q: Can geomembranes be used in gas barrier applications?

- Yes, geomembranes can be used in gas barrier applications. They are commonly used to prevent the migration of gases such as methane, radon, and volatile organic compounds (VOCs) in various industries including landfill sites, mining operations, and wastewater treatment plants. Geomembranes act as a barrier, preventing the gases from escaping into the surrounding environment and potentially causing harm.

- Q: What are the environmental impacts of geomembranes?

- Geomembranes, which are impermeable barriers used in various environmental applications, can have both positive and negative environmental impacts. On the positive side, geomembranes help prevent the migration of pollutants, such as hazardous chemicals, from contaminating soil, groundwater, and surface water. They also play a crucial role in preventing soil erosion and protecting sensitive ecosystems. However, it is important to consider the potential negative impacts as well. The production of geomembranes involves the use of natural resources and energy, which contribute to carbon emissions and other forms of pollution. Additionally, if not properly managed, geomembranes can become waste at the end of their lifespan, leading to disposal challenges and potential negative effects on ecosystems. To mitigate these impacts, it is crucial to adopt sustainable practices in the production, use, and disposal of geomembranes. This includes selecting materials with lower environmental footprints, implementing recycling and reuse programs, and ensuring proper installation and maintenance to maximize their lifespan.

- Q: Architectural glass film What are the benefits?

- 1, more economical. Both steel and transparent glass or colored glass paste heat reflective film than the replacement of heat-reflective glass to save 50% of the total cost, the remaining cases by analogy, for example: Original ordinary insulating glass were upgraded to a hollow heat-reflective coated glass or hollow Low-E coated glass paste after heat-reflective film or Low-E film. 2, more convenient. The window film is easy to operate, use of time shorter than changing a new window. 3, more environmentally friendly. Replace the window will produce large amounts of construction waste, transport and landfill costs will increase, and the glass film can be used both to heat and safety upgrades. But also to prevent indoor carpet, curtains, fabrics and paint fade, the effective protection of indoor furniture, computers and other office equipment, extending its life. 4, more secure. General insulation film also has some security enhancements, along with the clip (plastic) layer of glass fragments stick holding performance, its safety is better than glass, security professional security film stronger. 5, more healthy. Window film installation gel containing UV (ultraviolet) absorber, can block 98% -99% of UV rays. 6, more light. If you change a hollow glass, plus two glass hollow part of the total weight of the double or more, will greatly increase the building load.

- Q: Can geomembranes be used for waterproofing?

- Yes, geomembranes can be used for waterproofing. They are thin, flexible sheets made from various materials such as synthetic polymers or rubber, and are designed to provide an impermeable barrier against water. Geomembranes are commonly used in construction projects, such as lining ponds, landfills, or tunnels, to prevent water leakage and protect the surrounding environment. They are also used for waterproofing structures like basements or roofs, ensuring that water does not penetrate through the building materials.

- Q: Can geomembranes be used in floating covers for liquid storage tanks?

- Yes, geomembranes can be used in floating covers for liquid storage tanks. Geomembranes are impermeable liners that are commonly used to contain liquids and prevent leakage. In the context of floating covers for liquid storage tanks, geomembranes can provide an additional barrier to prevent liquid from escaping and protect the stored contents from external factors such as evaporation, contamination, or adverse weather conditions.

- Q: Are geomembranes suitable for use in seawater applications?

- Yes, geomembranes are suitable for use in seawater applications. Their impermeable and corrosion-resistant properties make them highly effective in preventing water seepage and protecting marine structures from the corrosive effects of seawater. Additionally, geomembranes are known for their durability and long lifespan, making them a reliable choice for various seawater applications such as lining ponds, reservoirs, and coastal protection systems.

- Q: How do geomembranes prevent leaks?

- Geomembranes prevent leaks by acting as a barrier between the liquid or gas being contained and the surrounding environment. These impermeable membranes are typically made of synthetic materials, such as polyethylene or polyvinyl chloride, which have low permeability to fluids. By providing a continuous and watertight lining, geomembranes effectively prevent the seepage or leakage of liquids or gases, ensuring the integrity and containment of the system they are installed in.

- Q: Water is the water base wallpaper wallpaper glue?

- Not, moisture-proof membrane is a professional alkali resistant, moistureproof, mouldproof wall treatment materials, which can effectively prevent the construction of the base surface of the tidal water and alkaline material extravasation

- Q: composite geo-membrane's introduction

- composite geo-membrane, it's widely used in canal seepage control project. In recent years, a large number of applications and their effectiveness of geosynthetics in civil engineering, in particular flood rescue project, attracts high attention of engineering and technical staff. For geosynthetics technology, from anti-seepage, filtration, drainage, reinforcement, protection and other aspects, our nation has proposed normative technical requirements, which has greatly accelerated the pace of the popularization and application of new materials. The material is widely used in the irrigation channel anti-seepage project, combined with the construction practice, we will talk about the application technology of geomembrane.

Send your message to us

TPO Geomembrane HDPE Pond Liners HDPE Geomembrane Smooth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords