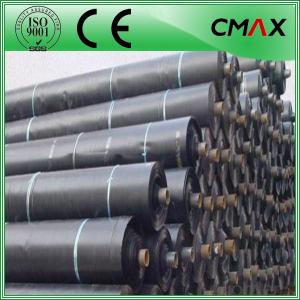

PE Geomembrane Liners with the Biggest liner factory in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geomembrane

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

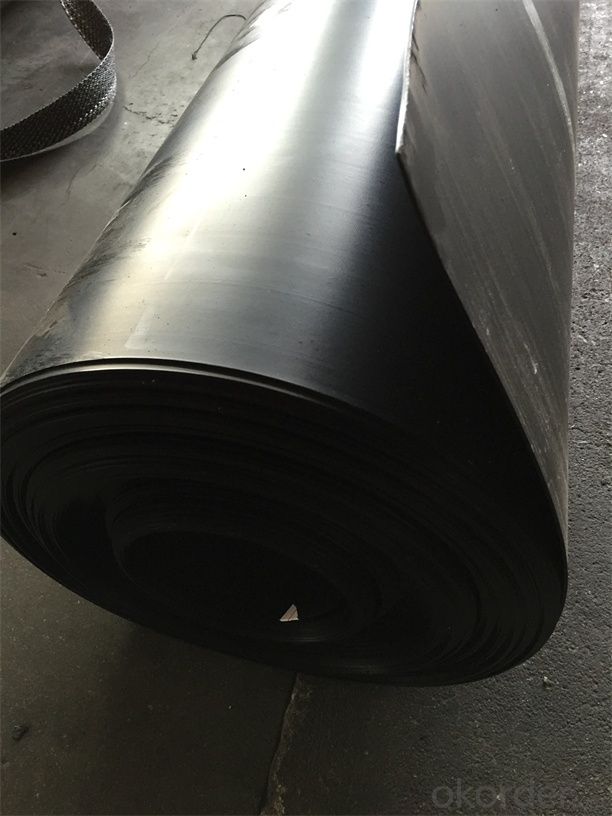

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

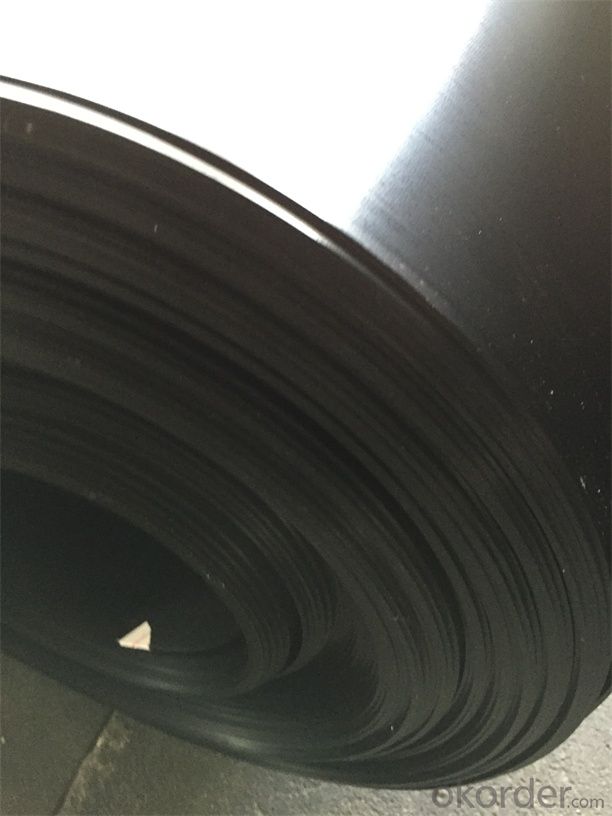

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

Geomembrane specifications

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

HDPE geomenbrane Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

HDPE Geomembrane Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

Gemembrane Show:

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q: Why imported geomembrane (HDPE) is most frequently used impermeable?material among artificial synthetic materials?

- There are many domestic geomembranes , and there is no need to import, after all they are not high-tech products.

- Q: Are geomembranes resistant to abrasion?

- Yes, geomembranes are designed to be resistant to abrasion. They are typically made from durable materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC), which provide excellent resistance to abrasion, punctures, and tears. This characteristic makes geomembranes suitable for various applications, including containment of liquids, gases, and solids in environmental protection and civil engineering projects.

- Q: How are geomembranes tested for quality control?

- Geomembranes are tested for quality control through a series of standardized tests and inspections. These include visual inspections to ensure there are no visible defects or damages, as well as physical tests such as tensile strength, puncture resistance, and thickness measurements. Additionally, geomembranes may undergo tests for chemical resistance, UV stability, and seam strength to ensure durability and performance. These rigorous quality control measures help to ensure that geomembranes meet the required standards and specifications for various applications such as environmental containment systems and civil engineering projects.

- Q: home decoration glass insulation film is good or posted stickers decorative film.

- Effect decorative film may be a little better, it looks good; since the insulation film with insulation function, appearance and life may be not better than decorative film.

- Q: How do geomembranes contribute to landfill construction?

- Geomembranes contribute to landfill construction by providing a barrier that prevents leakage and contamination of the surrounding soil and groundwater. These impermeable liners are placed at the base and sides of landfills to contain hazardous substances and prevent their migration into the environment. Additionally, geomembranes help to control the release of landfill gases, such as methane, which can be harmful to human health and the atmosphere.

- Q: Landfill final cover system uses geomembranes (HDPE high-density polyethylene film). It has advantages and disadvantages.

- at present, HDPE membrane is used to make closure material. HDPE film is anti piercing and anti aging. It is protective for it is of high density. the disadvantage is higher cost, easy aging in when exposed to sunlight, so it need covering by soil or geotextile.

- Q: Can geomembranes be used for decorative waterfalls?

- No, geomembranes are not typically used for decorative waterfalls. They are primarily designed for containment and lining applications, such as pond liners or landfill liners, and may not provide the desired aesthetic appearance for decorative water features. Other materials such as rocks, stones, or water-resistant finishes are usually used to achieve the desired look for decorative waterfalls.

- Q: What static eliminator is the best for large production equipment of geomembrane?

- 3024-L remote static eliminator is the best. The highest working voltage of the production equipment can reach 180KV. Otherwise, the quality of the products will decline seriously. So it is of great importance to eliminate static which can avoid the interference to production. At the place for reeling after dividing and cutting in the production equipment, the voltage of static electricity can reach 10KV which can be reduced by this eliminator.

- Q: What are the potential risks associated with geomembrane installation and use?

- The potential risks associated with geomembrane installation and use include improper installation leading to leaks or tears in the membrane, which can compromise its effectiveness in containing liquids or gases. Other risks include inadequate surface preparation, which can result in poor adhesion or sliding of the geomembrane. Furthermore, geomembranes can be vulnerable to punctures or damage from sharp objects, heavy machinery, or extreme weather conditions. Failure to regularly inspect and maintain the geomembrane can also lead to potential risks, such as undetected deterioration or degradation over time.

- Q: What should be noticed when geomembrane is welding?

- The success of sewage treatment seepage control project depends on the quality of the geomembrane itself and the quality of its installation and construction.

Send your message to us

PE Geomembrane Liners with the Biggest liner factory in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords