Polyethylene Fiberglass High Strength Geogrid Geotextile USA Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

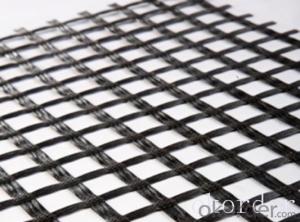

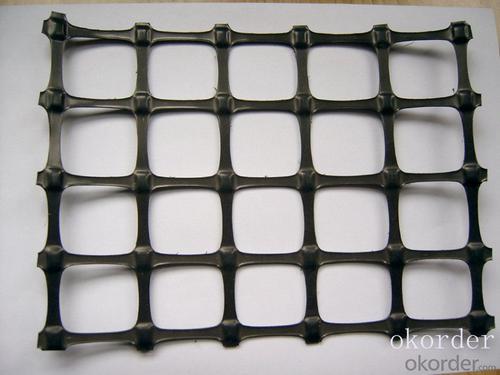

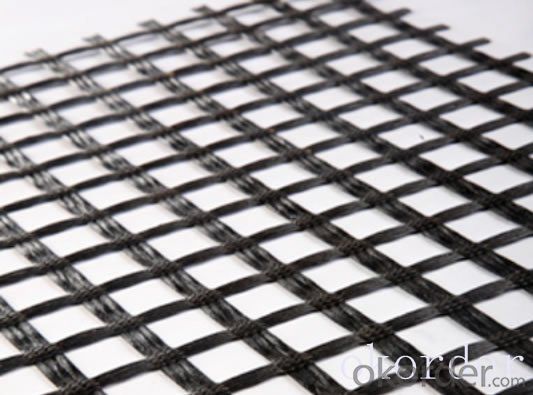

Biaxial

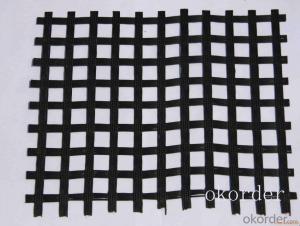

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different design considerations for geotextile applications?

- Some of the different design considerations for geotextile applications include the type and strength of the geotextile material, its permeability and filtration characteristics, its durability and resistance to degradation, the required tensile strength and elongation properties, as well as its installation and maintenance requirements. Other factors to consider include the anticipated loadings and stresses on the geotextile, the expected lifespan of the application, and any specific project requirements or environmental considerations.

- Q: Geotextile above allowed to plant grass?

- Geotextile above the grass To protect the slope, then the direct use of three-dimensional vegetation network can not Well! User name is the manufacturer phone! The The

- Q: What are the different geotextile durability test methods?

- There are several geotextile durability test methods used to assess the performance and longevity of geotextile materials. Some of the commonly used test methods include ASTM D4355 (Oxidative Induction Time), ASTM D1777 (Hydrostatic Puncture Resistance), ASTM D4533 (Trapezoidal Tear Strength), ASTM D4751 (Apparent Opening Size), ASTM D4759 (UV Stability), and ISO 12956 (Cyclic Load Test). These tests evaluate factors such as resistance to oxidation, puncture resistance, tear strength, opening size, UV stability, and cyclic load performance, providing insights into the durability and suitability of geotextile materials for specific applications.

- Q: How do geotextiles help with reinforcement of geogrid wall systems?

- Geotextiles help with the reinforcement of geogrid wall systems by acting as a separation and filtration layer. They prevent the mixing of different soil layers, which can compromise the stability of the wall system. Additionally, geotextiles help to distribute the loads evenly across the geogrids, enhancing their strength and overall performance.

- Q: What are the design considerations for geotextile-reinforced pavement systems?

- Some design considerations for geotextile-reinforced pavement systems include choosing the appropriate geotextile material, determining the optimal placement and orientation of the geotextile, considering the load-bearing capacity and stability of the pavement system, assessing the potential for soil erosion and filtration, and evaluating the long-term durability and maintenance requirements of the system. Additionally, factors such as climate, traffic volume, and site-specific conditions should be taken into account during the design process.

- Q: How are geotextiles affected by temperature variations?

- Geotextiles are generally resistant to temperature variations and can withstand a wide range of temperatures without significant impact on their performance. However, extreme temperature fluctuations, especially rapid changes, can potentially cause expansion or contraction of the geotextile material. This may lead to changes in its physical properties, such as reduced tensile strength or altered permeability. Overall, while temperature variations can have some effect on geotextiles, it is typically minimal and does not compromise their functionality significantly.

- Q: What are the disadvantages of using geotextiles?

- One of the main disadvantages of using geotextiles is their potential for clogging and reduced permeability. Over time, fine particles and debris can accumulate within the geotextile, leading to reduced water flow and drainage. Additionally, improper installation or lack of maintenance can cause geotextiles to shift or tear, compromising their effectiveness. Moreover, geotextiles may not be suitable for all soil conditions or applications, as they may not provide adequate stability or strength in certain situations.

- Q: What are the geotextiles?

- contact me

- Q: What are the considerations for geotextile selection in riverbank stabilization?

- When selecting geotextiles for riverbank stabilization, several considerations need to be taken into account. The first is the strength and durability of the geotextile, as it needs to withstand the erosive forces of the river and maintain its integrity over time. Additionally, the permeability of the geotextile is important, as it should allow for adequate water drainage while preventing the loss of fine soil particles. The installation requirements and methods should also be considered, as some geotextiles may require specialized equipment or techniques. Lastly, the cost-effectiveness of the geotextile should be evaluated, weighing the initial investment against the long-term benefits and effectiveness in stabilizing the riverbank.

- Q: Are geotextiles suitable for use in coastal erosion control?

- Yes, geotextiles are suitable for use in coastal erosion control. They can effectively stabilize soil, prevent erosion, and promote vegetation growth in coastal areas. Geotextiles provide a barrier against wave action and help to retain sediment, reducing the rate of erosion and protecting shorelines from further degradation.

Send your message to us

Polyethylene Fiberglass High Strength Geogrid Geotextile USA Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords