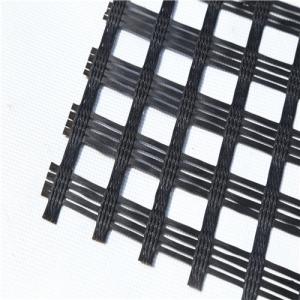

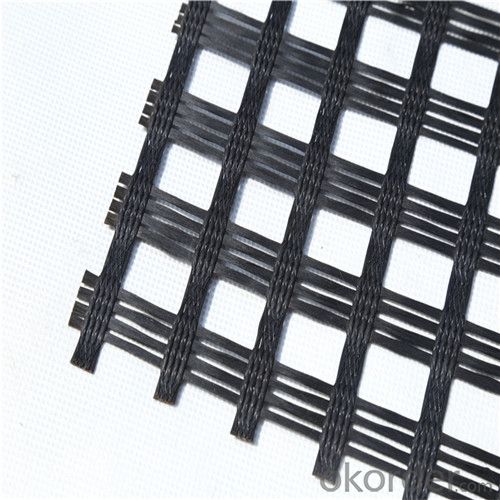

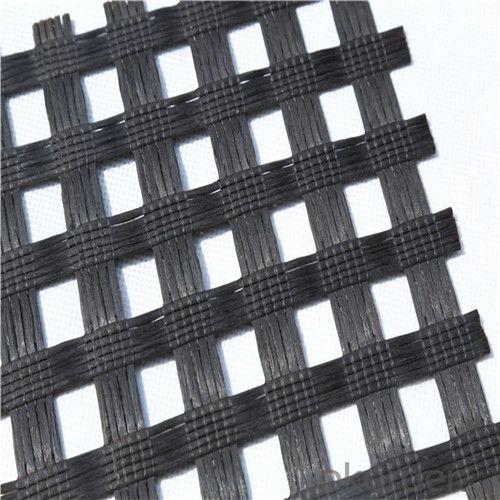

Fiberglass Woven Geogrid for Reforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Description

Fiberglass Geogrid is a kind of planar mesh using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives fully play of yarn strength and improves

Its mechanical property. It is coated with asphalt making full protection of the fiberglass matrix and greatly improving its wear and shear resistance.

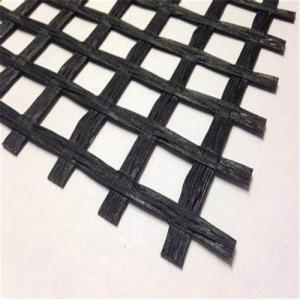

Fiberglass Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN,

Roll Size: 3.95x100m, as request,

Fiberglass Geogrid Property:

1) High strength, low elongation;

2) Heat-resistant, high modulus.

3) Light weight, good flexibility.

4) Anti-erosion, long life time.

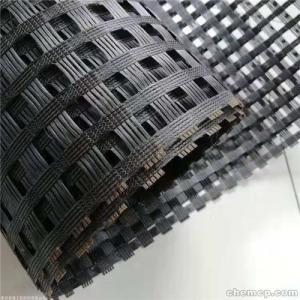

Fiberglass Geogrid Application

1) Roadbed reinforcement, prevent road surface crack.

2) Road reconstruction

3) Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

Fiberglass Geogrid

Packaging Details: PP bags or PE film. Or Packed as customers' requests;

Delivery Detail: 10-20days after the payment received.

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

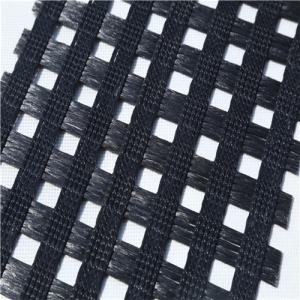

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their strength and stability. They provide reinforcement and prevent the spreading of cracks and ruts, increasing the pavement's resistance to traffic loads. Additionally, geogrids help to distribute the load more evenly across the pavement, reducing the potential for deformation and extending its lifespan.

- Q: Are geogrids effective in reducing differential settlement in foundations?

- Yes, geogrids are effective in reducing differential settlement in foundations. Geogrids are designed to distribute loads and improve soil stability, thereby minimizing differential settlement. By providing reinforcement and increasing the bearing capacity of the soil, geogrids help to equalize the settlement and prevent differential movement, ensuring a more stable foundation.

- Q: Are geogrids resistant to chemicals and environmental degradation?

- Yes, geogrids are generally resistant to chemicals and environmental degradation. They are designed to withstand exposure to various chemicals and harsh environmental conditions, ensuring long-term durability and performance.

- Q: Are geogrids effective in reducing soil erosion?

- Yes, geogrids are effective in reducing soil erosion. Geogrids provide stabilization and reinforcement to the soil, preventing it from being washed away by water or wind. They act as a barrier, holding the soil in place and reducing the chances of erosion occurring. Additionally, geogrids improve the overall strength and integrity of the soil, making it more resistant to erosion in the long term.

- Q: Are geogrids suitable for reinforcing steep slopes?

- Yes, geogrids are suitable for reinforcing steep slopes. Geogrids are commonly used in various civil engineering applications, including slope stabilization. They provide additional stability by distributing the forces exerted by the soil and preventing soil erosion. Geogrids are lightweight, flexible, and have high tensile strength, making them an ideal choice for reinforcing steep slopes and preventing potential landslides.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement to the soil structure, which helps distribute the load more evenly and prevent excessive settlement. They act as a stabilizing element by increasing the tensile strength of the soil, preventing its movement and settling.

- Q: Are geogrids suitable for use in reinforced soil slopes?

- Yes, geogrids are suitable for use in reinforced soil slopes. Geogrids are commonly used to enhance the stability and strength of soil slopes by providing reinforcement and preventing soil erosion. They are designed to distribute load and improve the overall performance of the slope, making them an effective solution for reinforced soil slopes.

- Q: Can geogrids be used in streambank stabilization applications?

- Yes, geogrids can be used in streambank stabilization applications. Geogrids are commonly used in these applications to reinforce and stabilize the soil, preventing erosion and providing structural support to the streambank.

- Q: Are geogrids suitable for use in high-temperature environments?

- No, geogrids are not suitable for use in high-temperature environments.

- Q: Are geogrids resistant to hydrocarbons?

- Yes, geogrids are generally resistant to hydrocarbons.

Send your message to us

Fiberglass Woven Geogrid for Reforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords