Voltex Bentonite Geotextile - Polyester/Polypropylene Short Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Polyester/Polypropylene Short Nonwoven Geotextile:

Short nonwoven geotextile made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commenly used to separate layers like clay and drainage and to protect liner from damage.

Main Features of Polyester/Polypropylene Short Nonwoven Geotextile:

1.Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction.

2.Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

3.Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

4.Excellent uniformity with high permeability and low pore size for soil filtration.

5.Supplied to a maximum width of 6.5mts,ensuring minimum waste over large construction areas.

6.100% polypropylene or polyester staple fibers ,needle punched and random network formation.

7.UV and rot resistant and biological degradation resistant.

Specifications of Polyester/Polypropylene Short Nonwoven Geotextile:

Item | Index | ||||||

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | |

Breaking strength at warp direction (kN/m) ≥ | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking strength at weft direction (kN/m) ≥ | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation at break (%) ≤ | 28 | ||||||

Trapezoid tearing strength( warp direction ) (kN) ≥ | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

Bursting strength (kN) ≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical permeability coefficient (cm/s) | 10-1~10-4 | ||||||

Effective pore size O95,mm | 0.08~0.5 | ||||||

Mass per unit area (g/m2) | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Mass error in unit area (%) | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 |

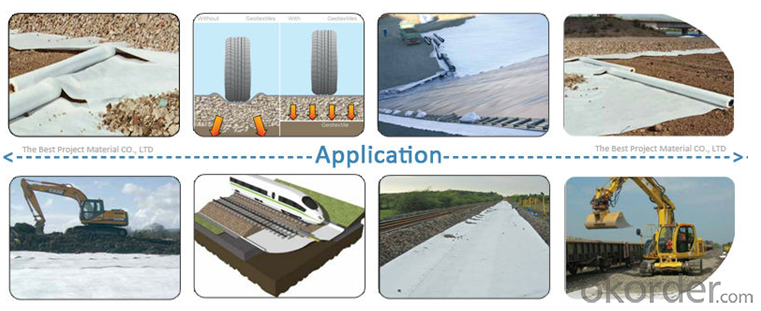

Applications of Polyester/Polypropylene Short Nonwoven Geotextile:

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

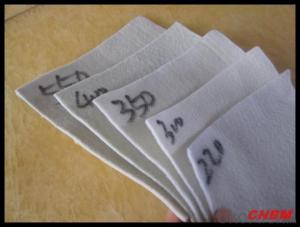

IMages of Polyester/Polypropylene Short Nonwoven Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the main functions of geotextiles?

- The main functions of geotextiles include filtration, separation, reinforcement, and drainage in various civil engineering and construction applications.

- Q: What are the considerations for geotextile selection in railroad projects?

- When selecting geotextiles for railroad projects, several considerations need to be taken into account. Firstly, the geotextile should have sufficient strength to withstand the loads and stresses imposed by train traffic. It should also possess excellent puncture resistance to ensure long-term durability. Additionally, the geotextile should have good filtration properties to prevent fine particles from entering the subgrade and causing drainage issues. It is important to consider the geotextile's permeability, as it should allow for adequate drainage to maintain the stability of the railway track. Lastly, the geotextile's compatibility with other materials used in the project, such as ballast or subgrade soils, should be evaluated to ensure proper functioning of the system.

- Q: Hope expert expert to give the answer

- The ditch is the ditch at the edge of the roadbed, mainly used to collect and exclude a small amount of surface water within the roadbed and flow to the roadbed; drainage ditch is the ditch, cut ditch, roadbed near the water discharged to the bridge or road Where the ditch in the natural river ditch. Geotextile is a kind of synthetic high strength fiber material which is used to improve the bearing capacity of subgrade when the bearing capacity of the foundation is poor. It has many kinds of fiber materials. The purpose is to improve the bearing capacity and prevent the cracks in the road surface.

- Q: Are geotextiles suitable for use in geocell mattress systems?

- Yes, geotextiles are suitable for use in geocell mattress systems. Geotextiles provide stability, erosion control, and reinforcement to the mattress system, making it an effective solution for soil stabilization and erosion prevention. They enhance the overall performance and durability of the geocell mattress system.

- Q: How do geotextiles help in preventing differential settlement?

- Geotextiles help in preventing differential settlement by providing additional support and reinforcement to the soil. These permeable fabrics are placed within the soil layers to distribute loads evenly, reduce soil erosion, and enhance stability. By improving soil strength and preventing the differential movement of soil layers, geotextiles help to minimize differential settlement and maintain a more uniform foundation.

- Q: How do geotextiles help in reducing soil compaction?

- Geotextiles help in reducing soil compaction by acting as a barrier between the soil and external forces such as heavy machinery or foot traffic. They distribute the load more evenly across the soil surface, reducing the impact and preventing excessive compaction. Additionally, geotextiles can enhance drainage and filtration, allowing water to flow through the soil more easily, which helps in maintaining soil structure and reducing compaction.

- Q: What are the advantages of using geotextiles in groundwater protection systems?

- Geotextiles offer several advantages in groundwater protection systems. Firstly, they act as a physical barrier, preventing the migration of pollutants and contaminants from seeping into the groundwater. This helps in safeguarding the quality and purity of the water source. Secondly, geotextiles provide filtration and separation capabilities, allowing water to pass through while retaining any suspended solids or particles. This enhances the overall efficiency of the groundwater protection system. Additionally, geotextiles are durable, resistant to degradation, and can withstand environmental stresses, ensuring long-term effectiveness in groundwater protection. Lastly, these materials are easy to install and maintain, reducing labor and maintenance costs associated with groundwater protection systems.

- Q: Can geotextiles be used in flood protection projects?

- Yes, geotextiles can be used in flood protection projects. Geotextiles are often used as a cost-effective and sustainable solution for erosion control, sediment filtration, and stabilization of soil in flood-prone areas. They can be used in various applications such as riverbank protection, levee reinforcement, and shoreline stabilization, helping to reduce the impact of floodwaters and prevent soil erosion.

- Q: Detailing the geotextile standard which, how to apply their own

- GB GB I specialize in the production of geotechnical materials

- Q: What are the key factors affecting the UV stability of geotextiles?

- The key factors affecting the UV stability of geotextiles include the polymer type, additives, and the thickness of the geotextile. The polymer type determines the inherent resistance of the geotextile to UV degradation. Additives such as UV stabilizers can enhance the UV resistance of the geotextile. Additionally, the thickness of the geotextile plays a role in its UV stability, as thicker geotextiles tend to provide better protection against UV rays.

Send your message to us

Voltex Bentonite Geotextile - Polyester/Polypropylene Short Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords