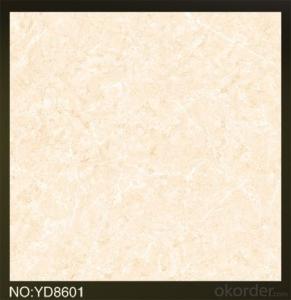

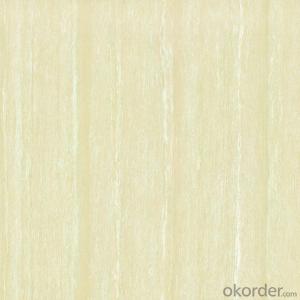

Polished Porcelain Tile Wooden Line Stone Serie CMAXWL004

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

Polished Porcelain Tile Wooden Line Stone Serie CMAXWL004 is one of the most popular color in the present market. Due to its simple design, this model has been exported to many countries in Middle East and Africa, and is also widely used in China domestic market. The wooden vein could create a clean special decoration effect.

Product Features

Polished Porcelain Tile, Soluble Salt

Only Grade AAA available

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, EN 14411

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 85 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 500x500mm, 7pcs/Ctn, 890 Ctns/20’Fcl, 1512m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 60*60 available?

—— Yes. For some series, the size 80*80, 100*100 and 60*120 are also available.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: How to remove the shoe oil into the tiles

- Also provided by Grammy Music Ceramics Tiles in the course of the use may be due to improper use of surface contamination caused by the phenomenon of common seepage of several treatment methods are as follows: 1, tea stains, fruit stains, coffee, jelly vinegar, shoes and other stains using sodium hypochlorite dilution (bleach), soak for 20-30 minutes after use with a cloth wipe; some infiltration of brick longer stains, soaking Time takes a few hours. 2, ink, anti-fouling wax moldy moldy, the use of sodium hypochlorite dilution (bleach). Use as long as the bleach applied to the stains soak for a few minutes to clean. 3, cement, scale, rust, rust using hydrochloric acid or phosphoric acid solution, can be wiped several times. 4, paint, oil, oil mark, the surface of anti-fouling wax layer using alkaline cleaning agent or organic solvents (and 5 ketone, triethylene), to paint to oil. 5, gum hammer decontamination Use: first use 20% -40% sodium hydroxide solution soak for 24 hours after the wipe with a cloth, and then 30% -50% hydrochloric acid solution soak for 30 minutes Cloth wipe clean. 6, ice cream use alkaline cleaning agent. 7, lime scale use of acid cleaner. Note: 1, more than the use of defibrillators need to wear plastic gloves. 2, the stains will be removed after the water to wash the brick surface. 3, the market or supermarkets have the latest decontamination detergent, can refer to the scope of the above decontamination and methods.

- Q: on to ceramic tile and was told by ace hardware to use acryl pro ceramic tile adhesive ive layed a few tiles but i dont think its right. need some help, is this the correct procedure?????

- I think ACE is telling you to hedge your bets. The adhesive on the back of floor tile is sensitive to heat, cold, and moisture. Using an additional adhesive should resolve that problem by providing more stick um.

- Q: The kind of tile is a good tiles?

- The higher the accuracy of the tile side, the better the effect after paving, buy high-quality tiles is not only easy to construction, but also save man-hours and accessories. With the tape measure the size of each tile around the difference between the high accuracy of the top grade. First-line brand Huidang's tiles very good. hardness Tiles with good hardness, toughness, not easy to rot on the top grade. To the edge of the tile fragments scratches each other to see the broken pieces of broken pieces is fine or loose, is hard, brittle or softer, is left scratches, or scattered powder, if the former is the top grade, the latter is quality difference. Whether the standard is the key to determine the quality of the tile, with a tape or caliper measurement of the diagonal and four sides of the tile size and thickness are uniform, good tiles, sound crisp sound, indicating high porcelain content. If the sound "blah" with a stubble sound, indicating that the brick contains cracks. Good tiles, the master is also easy to install the installation, the installation of the effect is also standardized. pattern Good tiles pattern, pattern color clear and consistent, delicate and delicate process, no obvious color, dislocation, broken line or inconsistency of the depth.

- Q: The house has been living for two years, these days do not know the weather is wet or how the matter, the bathroom tile actually fell a few pieces, but fortunately did not break. Now want to paste it back, I would like to ask, how to paste? With cement? Or what other glue? Do you want to drink again before There is also a problem with the brick at that time, but the closure or other problems? Another: Tiles are Mona Lisa. Thank you!

- Building materials store to sell plastic construction, smear to the back of the brick, paste it can be, I used n times.

- Q: I have a small bathroom (toilet only) that has carpet that smells and I want to replace it with 12 X 12 inch tiles. Is there a type of tile that will make the installation simple (avoid grout) and is easy to cut and easy to installHigher quality but simple installation is desired.

- Sorry, tile has to be grouted. It all installs the same way. It is really pretty simple to install, but you will need a tile saw or tile cutter and the proper tools. You will also want to remove the toilet during installtion. This way the tile will run up under the toilet base.

- Q: hello! if i have a connected dining room/kitchen and the kitchen has ceramic tile (that is old) and the dining room has carpet, can i just rip up the carpet and install vinyl tile over the ceramic then over the sub-floor without any issues?

- Sorry, read here yesterday that the vinyl tile adhesive will not adhere to ceramic tiles well but I'm not sure that's true and you cannot put any vinyl tiles over the ceramic tiles anyway because of the grout joints. There needs to be a very good smooth surface everywhere for any type of vinyl tiles or sheet vinyl flooring. The vinyl will sink into every grout line/joint and break as well as look terrible too. You will need to install some plywood underlayment over the existing ceramic tile first to give you a smooth sub-floor (most likely the 1/2 inch thick plywood). Or you could remove the existing ceramic tile and all the grout patch any rough /or uneven places on the existing plywood sub-floor and then install the new tile. Now you can put vinyl tiles over the wood sub-floor. There may be some uneven places or rough places where you'd need to use some floor patch /or floor leveler first. They make different size styles of floor transitions where the two floors meet so to give you a nice transition and look (if the kitchen floor is left the same or you installed underlayment and new tile).

- Q: I have plain jane 4 white ceramic tile and it does not go with my new room colors for my bath....can this be painted?

- Why don't you get Wallies or decals and decorate the white tiles? they are easy to remove if you get tired of the theme and don't cost a lot.

- Q: My kitchen is 15x11 and I am buying 18x18 tiles I need to know how many to buy.

- 18 x 18 = 18 sq in. which = 1.5 sq ft. 170 / 1.5 = 113.3 Buy about 130 of them, you'll have to cut some of them to get them to fit. Wouldn't hurt to buy 150 just in case.

- Q: Can a ceramic wall tile be applied directly to a greenboard surface with mortar or is a cement backer board required?Thanks for your help

- Wow, Hi Steve, My opinion, and I haven't read any other answers yet, Green board is fine for walls adjacent to areas that may endure water intrusion, but not as a substrate to install tile over. I understand it has been done, and certainly was an offered option before backer board was introduced, but it's water resistant properties are negligible. I do tile, every day of my life, and I get it that the customer is always right, even when they aren't, but I never had a negative call back, nor do I wish one for you, even years from now. Another positive aspect of the concrete backer board is texture; a surface allowing better adhesion for thin set, which green board does not offer. Good to see you again. I was beginning to wonder if you'd gotten lost in the SMOKIES. Steven Just my two sense

- Q: To re-do the kitchen so to change the previous, but the tiles left on the traces of viscose, how to remove it? Is there any good way? First, thank you

- You can wipe with steel sand. Steel sand is very delicate, knocked out the tiles, marble surface all stains are very effective in the sale of stainless steel products store for sale.

Send your message to us

Polished Porcelain Tile Wooden Line Stone Serie CMAXWL004

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords