Polished Porcelain Tile C-O36050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features Of Porcelain Tile:

1. Material: glazed porcelain

2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government and corporate projects, flooring tiles, deluxe clubs flooring

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

Primary Competitive Advantages Of Porcelain Tile

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets Of Porcelain Tile:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification Of Porcelain Tile

Tile type: | polished porcelain ceramic floor tiles |

Material: | Porcelain |

Size(MM) : | 600X600mm |

Thickness(MM: | 10mm |

Absorption: | <0.1% |

Color: | Available in all designs and colors |

Usage: | Used in floor |

Surface treatment: | Polished surface |

Features: | Professional triple-burning in oven, which makes our tiles more excellent quality. |

Function: | Heat-insulation, wear-resistant |

Packaging: | 4pcs/ctn,30kg/ctn,1.44spuare meters/box, one 20ft,27000kg container can load 20pallets,1267spuare meters/standard cartons and wooden pallets packing |

Delivery time: | Within 15 days after received the payment |

Payment terms: | L/C,T/T,30%deposit in advance, balance will be pay off before loading by T/T |

MOQ: | 1*20'FT |

Supply ability: | 10000spuare meters per day |

Remark: | All kind of designs can be produced according to your requirements |

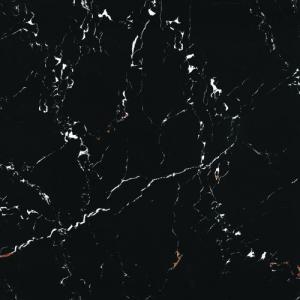

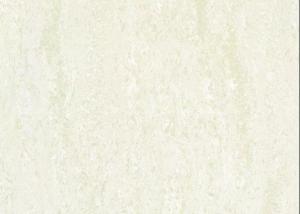

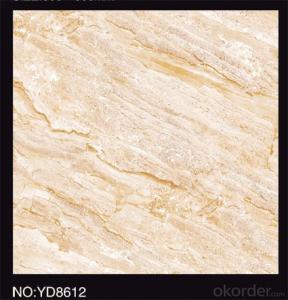

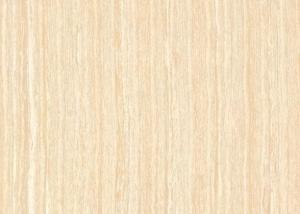

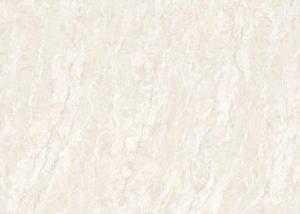

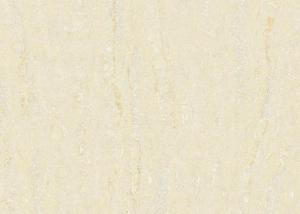

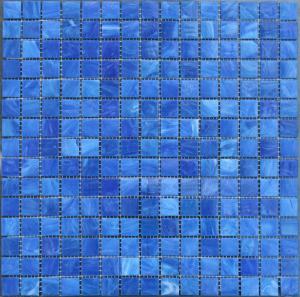

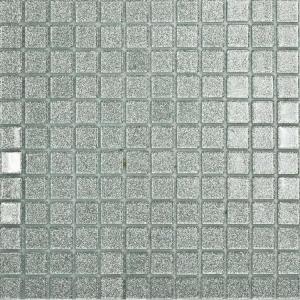

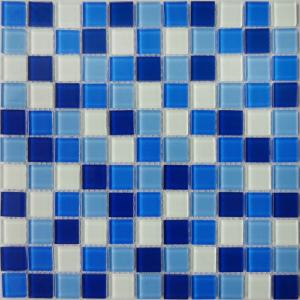

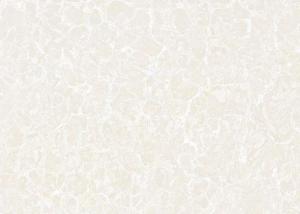

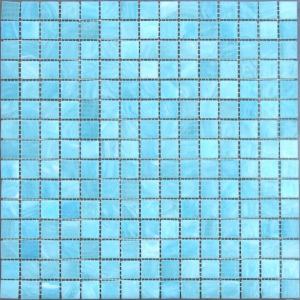

Product Pictures Of Porcelain Tile

- Q: I have some ceramic tiles in my kitchen floor that I would like to paint. Would this be possible?

- There is special paint for ceramic tiles but it would be less expensive to just re-tile. Rustoleum makes some cool stuff but very expensive and labor intensive.

- Q: I have just had a room tiled with porcelain tiles. They are non-shiny matte tiles and it was suggested to me that i should use a sealer. What sealer would be better to use, a water based or solvent based? What are the differences between using the two?

- Penetrating sealer.. Although a water based product, a couple of coats will last years. Mist on( w/ a spray bottle) wipe it thoroughly over the tile and grout with a damp cloth. I dampen a cloth with the sealer. Let set for 10/15 minutes and wipe excess off amd dry. Don t let it puddle and dry. Repeat at least once , twice if possible. The grout must be set for a minimum of 3 days with all the excess grout has all cleaned off. I ve have only used 2 brands over the years Cerama Seal and Miricle 511. I m sure theres others out there but I stick to what works.. Any questions you can e mail through my avatar and check my qualifications there. GL

- Q: Tomorrow I will be laying porcelain tile in my kitchen and need help in figuring out how to cut a hole in the tile for the floor vent? Any input would be appreciated.

- I've done this: I've used an angle grinder to cut a rectangle in one bathroom tile. Straight cuts are easy using an angle cutter and a diamond wheel designed for cutting tile. I've even cut a round hole for the commode. But the commode had a tile seam under it, so I wasn't cutting a hole in the middle of a tile, I was able to cut and nibble away until I had a semi-circle in each tile. Just make sure you have more tile than you need. If (when) you make a mistake you have more to work with. And don't try to accomplish the entire cut all at once. Take little passes at it until you work your way through. Hope this helps. 'av'a g'day mate. '')

- Q: After completing a bathroom tile job, including a tile baseboard border about 6 up from the floor, we have dried thinset in on the actual wall - places we missed during cleanup. I‘ve tried using some scrapers (plastic and metal), and the dried thinset is like concrete (naturally) and is pulling layers of drywall off with it. Is there a solvent or better way to remove the dried thinset from both the wall and the exposed rim of the tiles? As a last resort I might be okay with slight damage to the walls as they need serious prep anyway before paint, but I do want to make sure i haven‘t missed some very obvious, easier, better solution first.

- I have had tile layers do that to my drywall talking about PO! OK take a razor knife and carefully cut the paper around the grout peel paper away, then skim coat with mud, tapping mud you know loose. Best case if you are going to texture the wall if its not thick on the surface just texture it in. If a tile layer caused this tell him to pay for it or get out of town!

- Q: Can I use talavera tiles for this? The porch is concrete and was painted at one time. Looks like the last owners removed the paint, but then left it as is. Is talavera tile ok to use on an outdoor porch. I don‘t know much about it, I‘ve only seen pictures and think it‘s beautiful! Thanks!!

- any tile you like is okay to use. my advice would be to prepare the surface by cleaning it thoroughly then using a concrete adhesive before setting your tile with white thinset mortar. after grouting , be sure to use a sealer to prevent moisture getting under the tiles. the sunlight will expand the water and cause vaporlock that will pop your tiles. then maintain by resealing at least once ayear.

- Q: Im trying to figure out how to apply (vct) Vinyl tile squares? Whats the best way to start a project? What adhesive do you use if any? Is it like ceramic with some form of grout? etc!

- On VCT, Vinyl Composite Tile, you need adhesive to put it down and it goes together directly next to each other, you do not grout VCT. You also need a heat gun and a VCT cutter when installing. The manufacturer of the VCT also makes the adhesive that is needed for installation. After it is installed it needs have a weight roller rolled over the tile to ensure it sticking to the floor. VCT should also be sealed and waxed after completion to ensure it won't be scratched and that no moisture gets underneath the surface. You can lay out the tiles before the adhesive is applied to see what it looks like and where the cuts will be, you don't need to lay out the whole floor just a little bit. You can chalk line the floor with a straight edge to ensure the VCT is being laid in a straight line. You may be able to get on the Armstrong, Congoleum, or Mannington website for more info.

- Q: Move the new home decoration for the living room floor wood or tiles hesitant, I personally prefer some of the floor, feel very warm on the grade of the feeling, and the bedroom is the floor, all the wood flooring will make home more sense of coordination, but the tiles Practicality a little higher, so clean, more durable, so under the very hesitant, ask for advice ~

- If you have time to take care of the wood floor with it. The If you are lazy or tiles fit.

- Q: are there any products made for removing grout off of tile because we forgot to clean the grout off of our tile and it dried over night and now its hard and is stuck pretty well. does anyone know of any acids or anything made for this?

- Did a lot of tiling with my father...and id be the one who would have to clean. This is wut u do. Take a 5 gallon bucket or just any bucket. Fill it with warm water. Take a big sponge and wash the tile. you are going to have to do this a lot of times. probably about 5 times. if there are big pieces of grout, u should be able to pick it off with your finger. DONT USE A RAZOR! you will scratch the tile. just warm water n a sponge. change your water frequently and make sure ur sponge is clean!

- Q: Hi,We put porcelain tiles on our kitchen floor.Unfortunately the contractor did not do a great job. He did not clean it properly and now the grout is all over the tiles. its been 1 month the they put the tiles. How can I take grout off the tiles? I got a grout cleaner from Home depot but its not working as it should be. Please advise

- It feels like the sealer wasn't utilized. you are able to re grout yet you will might desire to kill the mold in it first. If bleach did no longer artwork and only made it darker, i think of it fairly is defiantly no longer sealed. it is kinda like whilst it rains then the sidewalk outdoors turns darker because of the fact it has absorbed countless the water.

- Q: can you use marble tile for counter top

- Marble countertop are unmatchable in their natural beauty and classic elegance and no other worktops can even come close to the regal look they impart to modern kitchens. Amongst marble countertops, the ones that are highly prized and usually preferred are white marble worktops, most notably the brand Carrara marble worktops. With various advantages like More Design Capabilities, Timeless Appeal, It is cool by Nature, Resistance to Heat, High Durability, It is very easy to find and many other. Get more details at:

1. Manufacturer Overview

| Location | Sichuan, China (Mainland) |

| Year Established | 1987 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Hong Kong; Macau |

| Company Certifications | ISO 9001:2008;CCC,CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen Port, China |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 239 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 26000.00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Polished Porcelain Tile C-O36050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20' FCL m²

- Supply Capability:

- 100000 M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches