Aluminum Sheets Lebanon - Polyester Aluminum Panel Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Ployester Aluminum Panel Sheet Description:

Ployester Aluminum Panel Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on. Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Ployester Aluminum Panel Sheet:

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and JIS

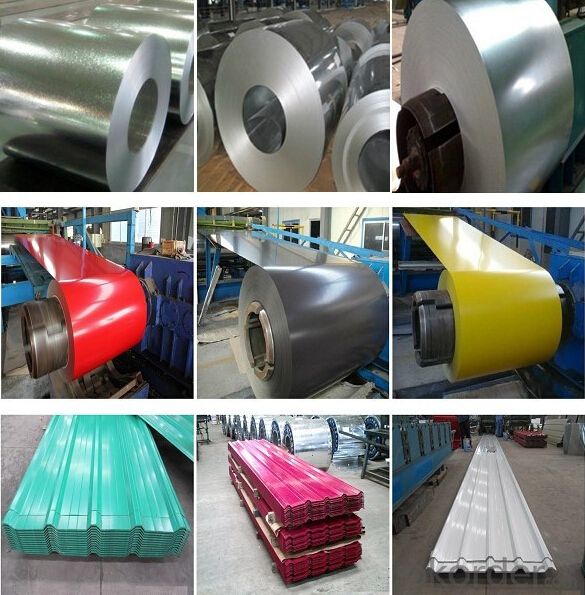

3. Ployester Aluminum Panel Sheet Images:

4. Ployester Aluminum Panel Sheet Specification:

| Commodity | Enameled aluminum panel, Marble aluminum panel, Wood grain panel, Wire grain aluminum panel, PVDF coating aluminum panel. Aluminum alloy A3003, A5052 high quality aluminum plate |

Surface coating | PVDF , Polyester |

| Color | All colors, Enamel grain, Marble grain, Wood grain, Wire drawing |

| Total thickness | 1.5mm,2.0mm, 2.5mm, 3.0mm |

| Standard dimension | 1220mm*2440mm |

| Warranty | More than 15 years |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..

- Q: This question asks for an identification of various types of aluminum sheets that are typically utilized in construction projects.

- <p>Aluminum sheets used in construction come in various types, each with specific properties and applications. Common types include: 1) Mill Finish Sheets: These have a natural aluminum finish and are used for applications requiring a raw aluminum look. 2) Painted Aluminum Sheets: Coated with paint for enhanced durability and color options, suitable for exterior applications. 3) Anodized Aluminum Sheets: Durable and corrosion-resistant, often used for architectural features. 4) Embossed Aluminum Sheets: Offered with various textures for design purposes. 5) Perforated Aluminum Sheets: Used for decorative or functional purposes, such as ventilation. 6) Aluminum Composite Material (ACM) Sheets: Consisting of two aluminum sheets with a non-aluminum core, used for cladding. Each type is chosen based on the project's specific requirements for aesthetics, strength, and environmental resistance.</p>

- Q: Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Indeed, the utilization of aluminum sheets is appropriate for the production of aircraft fuselages. Aluminum remains a favored selection for aircraft assembly owing to its exceptional strength-to-weight proportion, ability to withstand corrosion, and simplicity in fabricating. Its lightweight nature aids in the reduction of the aircraft's total weight, thereby enhancing fuel efficiency and augmenting payload capacity. Moreover, aluminum exhibits remarkable resilience in enduring the pressures and tensions encountered during flight. Furthermore, it is a readily accessible and economically viable material, rendering it a pragmatic preference for aircraft manufacturers.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Aluminum sheets have multiple uses in decoration and architecture. This versatile material can be easily shaped and molded into various forms, making it perfect for a wide range of architectural projects. It is commonly utilized in exterior cladding, roofing, window frames, and facades, lending a sleek and contemporary appearance to buildings. Moreover, aluminum sheets are also employed for decorative purposes like wall panels, art installations, signage, and furniture. Architects and designers often choose aluminum due to its lightweight and durable properties, enabling them to create visually appealing and functional structures. Additionally, aluminum's resistance to corrosion makes it suitable for both indoor and outdoor applications.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Yes, aluminum sheets are suitable for furniture manufacturing. They are lightweight, durable, and resistant to corrosion, making them an excellent choice for various furniture applications. Additionally, aluminum can be easily shaped and fabricated, allowing for versatile designs and styles.

- Q: Are aluminum sheets non-magnetic?

- Yes, aluminum sheets are non-magnetic. Aluminum is not a ferromagnetic material, which means it does not have strong magnetic properties. It is classified as a paramagnetic material, which means it has a weak response to magnetic fields. Therefore, aluminum sheets do not attract or hold a magnet.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Densities: Aluminum: 2,710 kg/m^3 Copper: 8,940 kg/m^3 Basis: 1 m^3 of copper-aluminum alloy mass of aluminum in 1 m^3 alloy = 519 kg vol. of aluminum in the 1 m^3 alloy = 519 kg/(2710 kg/m^3) = 0.1915 m^3 vol. of copper in 1 m^3 alloy = 1 m^3 - 0.1915 m^3 = 0.8085 m^3 mass of copper in 1 m^3 alloy = (0.8085 m^3)*(8,940 kg/m^3) = 7,227.87 kg mass of the m^3 alloy = 7,227.87 kg + 519 kg = 7,746.87 kg %weight of aluminum = (519 kg/7,746.87 kg)*100% = 6.70% The alloy has 6.70% by weight of aluminum in it.

- Q: What are the different types of patterns available for textured aluminum sheets?

- There are various types of patterns available for textured aluminum sheets, including stucco, diamond, pebble, hammered, and brick patterns. These patterns are created through embossing or rolling processes, providing different textures and visual effects for decorative or functional purposes.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

Send your message to us

Aluminum Sheets Lebanon - Polyester Aluminum Panel Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords