Geogrids and Geomembranes - Butimen Coated Fiberglass Geogrid for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

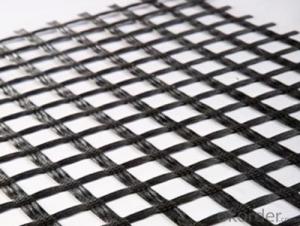

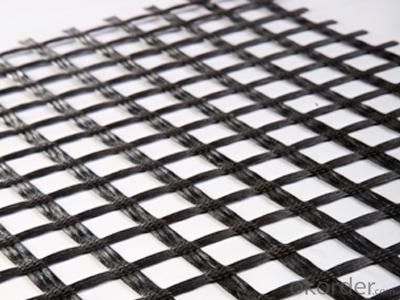

Structure of Butimen Coated Fiberglass Geogrid:

Butimen Coated Fiberglass Geogrid is excellent composite material used for road bed reinforcement and soft soil foundation improvement. It has become an indispensable material in treatment of reflection cracks on asphalt road surface. The products are semi-rigid mesh base made from high-strength alkaline-free glass fiber through international advanced process and subjected to surface coating. It has a high tensile strength and a lower elongation both vertically and horizontally. Moreover, it has good resistance to high and low temperature, aging and corrosion. It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

Main Features of Butimen Coated Fiberglass Geogrid:

fiberglass geogrid for soil reinforcement

fiberglass geogrid

High tensile strength, low elongation

High stability

Butimen Coated Fiberglass Geogrid Images

Butimen Coated Fiberglass Geogrid Specification

Glass Fiber Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids suitable for reinforcing bridge abutment backfills?

- Yes, geogrids are suitable for reinforcing bridge abutment backfills. Geogrids are commonly used in civil engineering projects to enhance soil stability and provide reinforcement. They can effectively distribute the load and prevent soil movement, thereby improving the overall strength and performance of bridge abutment backfills.

- Q: How are geogrids connected to the surrounding soil?

- Geogrids are connected to the surrounding soil through a process called interlocking. The geogrids have openings or apertures that allow the soil particles to pass through. As the soil is compacted and fills these apertures, it creates a mechanical bond between the geogrid and the soil. This connection enhances the stability and load-bearing capacity of the soil, preventing lateral movement and reinforcing the overall structure.

- Q: What are the types of Geogrid

- Glass fiber geogrid, 1595341 polyester fiber geogrid, glass fiber, polyester composite geotextile, steel plastic composite geogrid, PP grid, one-way two-way stretching plastic geogrid,

- Q: What are the applications of geogrids in civil engineering?

- Geogrids have numerous applications in civil engineering, primarily in soil stabilization and reinforcement. They are extensively used in road construction to improve the strength and stability of the subgrade and prevent rutting and cracking. Geogrids also find applications in retaining walls, embankments, and slopes, where they enhance the bearing capacity and reduce soil erosion. Additionally, they are utilized in landfills to enhance the stability of waste materials and in pavement overlays to reduce reflective cracking. Overall, geogrids play a crucial role in enhancing the durability and performance of various civil engineering structures.

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint. The use of polyethylene production by Seiko weaving. Color usually green or blue.

- Q: What is the effect of cyclic loading on geogrid behavior?

- Cyclic loading on geogrid behavior can have detrimental effects, such as increased deformation and reduced strength over time. This repeated loading and unloading can lead to progressive damage and degradation of the geogrid, compromising its ability to provide reinforcement and stabilization. Therefore, it is important to consider the potential impact of cyclic loading when designing and implementing geogrids in construction projects.

- Q: Are geogrids effective in stabilizing riverbanks?

- Yes, geogrids are effective in stabilizing riverbanks. Geogrids provide reinforcement and structural stability to the soil, preventing erosion and maintaining the integrity of the riverbank. They help distribute loads and reduce the potential for slope failures, making them a reliable solution for stabilizing riverbanks.

- Q: Are geogrids effective in preventing soil erosion on coastal cliffs?

- Yes, geogrids are effective in preventing soil erosion on coastal cliffs. Geogrids provide structural support to the soil and enhance its stability, reducing the risk of erosion caused by wave action and weathering. They help to distribute the forces exerted on the soil and prevent surface runoff, thereby protecting the cliffs from erosion and maintaining their integrity.

- Q: Can geogrids be used in stabilization of coastal dunes?

- Yes, geogrids can be used in the stabilization of coastal dunes. Geogrids are effective in providing reinforcement and preventing erosion in sandy and loose soil conditions. By installing geogrids, the dunes can be strengthened, reducing the risk of erosion and maintaining the stability of the coastal area.

- Q: What kind of geogrid can meet the requirements

- If it is reinforced soil retaining wall or steep slope, the use of polyethylene products: Specifications: TGDG80 (HDPE), do not know how to view the national standard: GBT17689-2008

Send your message to us

Geogrids and Geomembranes - Butimen Coated Fiberglass Geogrid for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords