High Density Polyethylene Geocell with Bitumen Geomembrane CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of High Density Polyethylene Geocell:

Our geocell canbe made of PP/HDPE/plastic,

length:6.22m ;

thickness: 1-2mm

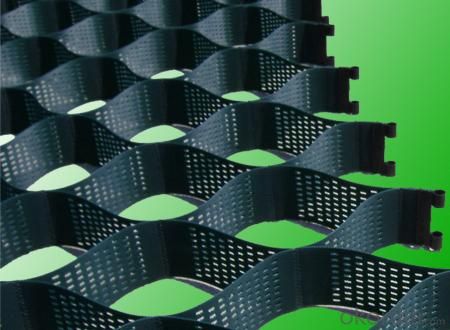

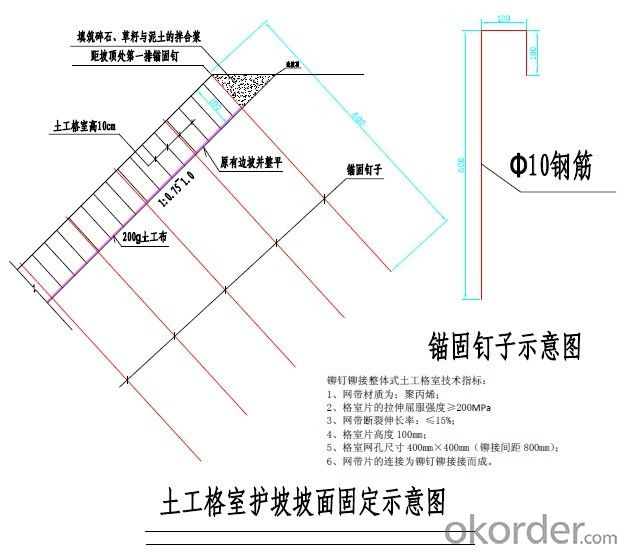

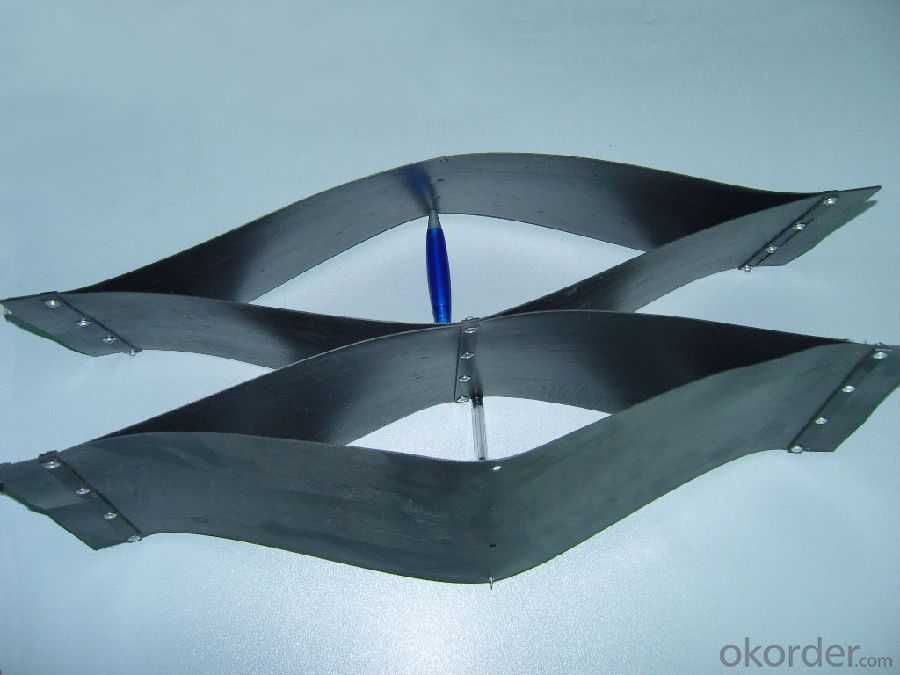

Geocell is a net-shaped cell structure made by welding high intensity thermoplastic sheet. It is flexible folded during service, and forming into struct with powerful lateral confinement and rigidity.

It can be used as cushion coat to strengthen loading capacity of weak ground or slope protection

structure, as well as stop structure, and so on.

Main Features of High Density Polyethylene Geocell:

1. Fix railway ground .

2. fix weak ground of roads .

3. block loading capacity.

4. treat river way of shallow water.

5. act as support in pipeline and sewer.

6. act as comprehensive block stopping land sliding and bearing loading capacity.

7. act as independent wall, dock and break-water.

8. treat desert, beach, riverbed and bank.

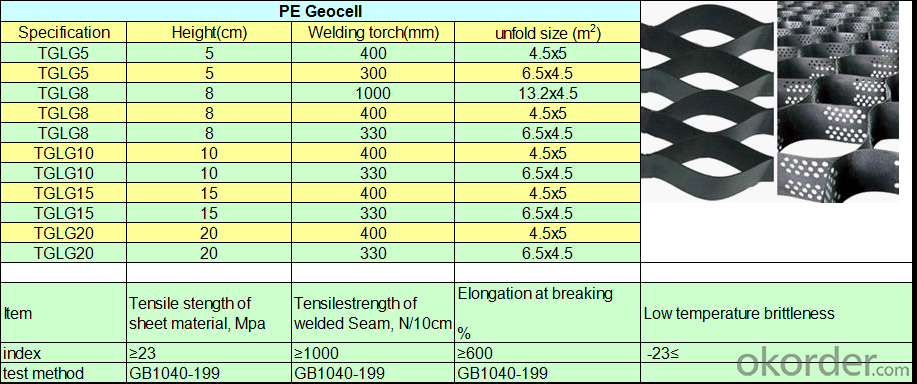

Specifications of High Density Polyethylene Geocell:

1.TGLG5 TGLG8 TGLG10 TGLG15 TGLG20(CM)

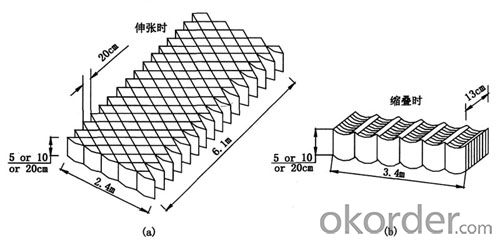

2.Stretch size :4mx5m or 6m x7m or at your request.

3. General roadbed reinforcement with 330 mm, 400 mm.

Slope protection with 500 mm, 660 mm

4.Executive standard:GB/T19274-2003

Technical specification of geocell

Applications of High Density Polyethylene Geocell:

1. processing half fill Semi roadbed

build up the embankment on the ground on the slopes of the natural slope ACTS in 1:5, supporting subsoil should dig the steps, The step width shall be less than 1 m, when building or rebuilding roads widened by installments, Convergence between the new and old roadbed fill slope ,should dig the step, high grade highway width is 2 m, laid large geocell in each of the steps horizontally, using the large geocell of their own facade confining reinforcement effect, better solve the problem of uneven settlement

2. subgrade in wind drift sand region

Sand subgrade should be given priority to with low embankment, region filling height not less than 0.3 m. generally due to its low subgrade, sand subgrade construction in professional requirements and heavy load, adopting large chamber loose packing confining effect, can be in limited the height of the roadbed with high stiffness and strength, to inherit the load stress of large vehicles.

3. Reinforced back subgrade soil

Using large geocell can better achieve the goal of abutment back reinforced , can generate enough friction between the geocell and packing . and effectively reduce roadbed uneven subsidence, finally can effectively relieve the abutment jump car "disease early impact damage of bridge deck.

4. subgrade in permafrost region

In permafrost regions fill roadbed construction, should reach a minimum filling height in order to prevent or cause a frozen layer ceiling Frothing decreased, resulting in an excess of embankment settlement occurs. Geocell unique overall unconfined facades reinforced effect and effectively implemented, can ensure a minimum filling height in some special area to the maximum extent, and to fill a high-quality strength and stiffness.

5. The collapsibility loess roadbed treatment

When the highway and the highway collapse loess and loess lot better compression by wet, or foundation bearing capacity is lower than the high embankment to allow third-party vehicle load and weight of pressure embankment, subgrade bearing capacity requirements should also for processing, then the superiority of Geocell on manifest is no doubt.

IMages of Plastic Geocell/HDPE geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can geomembranes be used for lining tunnels?

- Yes, geomembranes can be used for lining tunnels. Geomembranes are impermeable sheets made of synthetic materials that are designed to provide a barrier against water, chemicals, and other substances. They are commonly used for various applications in civil engineering, including tunnel lining. Geomembranes can help prevent water infiltration, soil erosion, and the migration of harmful materials, providing structural integrity and environmental protection to tunnels.

- Q: Which is better for ceramic film and organic film ?

- Each have their own advantage, because the two are different in nature

- Q: how to remove the oxidation of the packaging film of aluminium alloy door and window by the sunlight?

- Try using a solution of diluted paint, as well as alcohol and acetone solution (because they are all organic solvents). But I think that the kind of diluted paint would be easy to use. Here we call it releasing the receiving water, it may also be called lacquer thinner.

- Q: How do geomembranes prevent liquid and gas migration?

- Geomembranes prevent liquid and gas migration by acting as impermeable barriers that effectively seal off the underlying soil or substrate. These synthetic liners are designed to have extremely low permeability, meaning they do not allow the liquid or gas to pass through their structure. By effectively containing the fluid or gas in one area, geomembranes prevent any migration or leakage, thereby protecting the surrounding environment from contamination or loss of valuable resources.

- Q: Are geomembranes resistant to chemical degradation?

- Yes, geomembranes are generally resistant to chemical degradation. They are designed to withstand exposure to a wide range of chemicals and can provide effective containment and protection against chemical substances. However, the level of resistance may vary depending on the specific type of geomembrane material and the chemicals involved. It is important to consider the compatibility of the geomembrane with the intended chemicals and conduct proper testing or consult with experts to ensure long-term performance.

- Q: How do geomembranes contribute to the prevention of slope erosion?

- Geomembranes contribute to the prevention of slope erosion by acting as a barrier between the soil and the surrounding environment. They provide a waterproof and impermeable layer that helps to control water flow and prevent the infiltration of moisture into the soil, which is a common cause of slope erosion. By effectively reducing water seepage and preventing soil movement, geomembranes help to stabilize slopes and protect them from erosion.

- Q: Architectural glass film benefits include:

- Architectural glass film according to their functions can be divided into: Privacy film, decorative film, energy-saving insulation film, explosion-proof membrane, bullet-proof film, a film in which the explosion-proof and bullet-proof membrane can also be assigned to the category of the security film. According to the production process is divided into: Staining film, film clip, colors film, quantum film. Usually on the market of low-cost shoddy glass film membrane staining, mostly because it does not really have the energy-saving insulation anti-ultraviolet, and other functions, and life is short, mostly two to three years will fade off . Clip film is a film based on the original film on the additional plating up, and compare it with the film in terms of staining is usually longer life, but over time will slowly fade. According to architectural glass film classification: EEB film, security film and indoor decoration membrane. Function is different. Basic includes the following features: First, comfort and energy saving, always enjoy - energy-saving insulation, adjust the indoor temperature, saving money. Second, the protection of interiors and occupants of buildings - blocking more than 99% of harmful UV rays, protect the body health and prevent fading of furniture; outer shield sight, create a private space; shock-proof, reducing accidental injury; construct; invisible network security; the protection of private property Third, to improve the overall appearance of the building, to build a harmonious working environment IV reduction. annoying glare - to block sun glare, prevent light pollution, protect eyesight V. improve the efficiency of the company's employees - a variety of fancy, beautify the living room appearance, improve the indoor environment VI, explosion-proof, shock-proof, reduce injuries. build; invisible security net; protection of private property.

- Q: How is the oil film on the fish tank produced?

- The reason why the bubble on the fish tank does not break is because that the water is eutrophic, which can be solved by increasing filtration, reducing feed intake or frequently changing the water.

- Q: What is the role of geomembranes in groundwater protection?

- The role of geomembranes in groundwater protection is to act as a barrier or lining system to prevent the contamination of groundwater by hazardous substances. By providing a impermeable layer, geomembranes prevent the transmission of pollutants from waste storage facilities, landfills, or other potentially harmful sources into the underlying groundwater. This helps to safeguard the quality and availability of groundwater resources, ensuring their sustainability and protecting public health and the environment.

- Q: What are the technical requirements of permeable geotextile of two fabrics and one membrane?

- The indicators of porous composite membrane of two fabrics membrane: breaking strength 5kn, bursting 1.1kn, tearing 0.15kn, stripping 6n/cm or stripping is not found in breaking of base material. 2008 standard gram weight has required that the original standard should be lower than 360g.

Send your message to us

High Density Polyethylene Geocell with Bitumen Geomembrane CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords