Ultrasonic Geocell for Slope Pavers Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE Geocell with CE Certificate

Our company manufacturing production line equipment Geocell is determined by more than one combination of ultrasonic plastic welding machine adopts imported PLC control has the following advanced features

Main Features of HDPE Geocell with CE Certificate

1, touch-screen display and parameter setting, imported piezoelectric ceramic transducer.

2, color touch-screen control panel.

3, multi-language you set,

4 levels of adjustable mold design, mold fast and easy adjustment.

5, the new power amplifier circuit, power is more robust, more durable transducers,

6, frequency automatic tracking, a variety of parameter settings.

Specifications of HDPE Geocell with CE Certificate

TEST METHOD | TEST VALUE | |

Polymer Density | ASTM D 1505 | .941 g/cc - .960 g/cc |

Sheet Gauge | ASTM D 5199 | 50 mil + 4 mil |

Carbon Black Content | ASTM D 1603 | 1.5 percent minimum weight carbon black |

Environmental Stress Crack Resistance (ESCR) | ASTM D 1693 | 4,000 hr. minimum |

Seam Hang Strength | 4” (101.6 mm) weld joint supporting load of 160 lb. (72.5kg) OR | 30 days minimum |

4” (101.6 mm) weld joint supporting load of 160 lb. (72.5 kg) while undergoing temperature change from 74oFto 130oF (23oC to 54oC) on 1 hour cycles | 7 days minimum | |

Seam Peel Strength, minimum | U.S. Army COE Tech Report | Cell Seam Strength 65.5 lb (292 N) per inch of Cell Depth |

Applications of HDPE Geocell with CE Certificate

Slope Pavers

1. automatic control easy to operate

2.imported parts with CE certification

3.prompt delivery

now most of our products are exported to Chile,Mexico,Brazil, Argentina , Russia, Poland, Turkey, USA, UK, Iran,and etc.

Concrete construction method

1.Open the superimposed geocell.

2.Fixed with nails or connected with the framework of stretching device.

3.Fill the particle filler until the full and beyond standard room to the top, then vibrate or roll to finish the primary work.

4.At this point, cell chamber system can support all kinds of construction equipment. The construction can be done directly in the above.

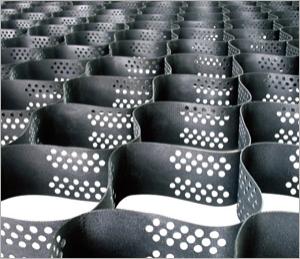

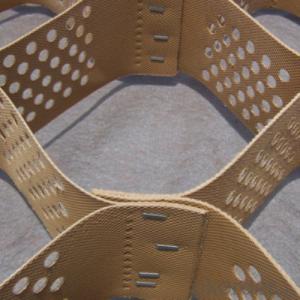

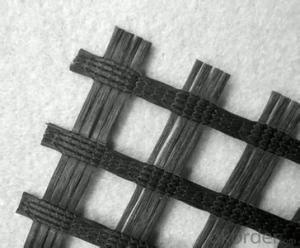

IMages of HDPE Geocell with CE Certificate

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q: Can geocells be used in load-bearing platforms for temporary structures?

- Yes, geocells can be used in load-bearing platforms for temporary structures. Geocells are cellular confinement systems that provide stability and reinforcement to the ground. They are designed to distribute the load evenly and improve the load-bearing capacity of the platform. Their flexible nature allows for easy installation, making them suitable for temporary structures where quick and efficient construction is required.

- Q: Can geocells be used in wastewater treatment?

- Yes, geocells can be used in wastewater treatment. They can be utilized in constructing containment structures, such as wastewater lagoons or treatment ponds, to provide stability, prevent erosion, and improve the overall efficiency of the treatment process. Geocells can help in reducing the risk of leakage and contamination, as well as enhancing the structural integrity of the treatment system.

- Q: Can geocells be used in dam construction?

- Yes, geocells can be used in dam construction. Geocells are a type of geosynthetic material made from high-density polyethylene strips that are interconnected to form a honeycomb-like structure. They can be filled with soil or other granular materials to create a stable and reinforced structure. In dam construction, geocells can be used for erosion control, slope stabilization, and strengthening of embankments, thereby enhancing the overall integrity and longevity of the dam.

- Q: Can geocells be used in wastewater treatment systems?

- Yes, geocells can be used in wastewater treatment systems. Geocells are three-dimensional cellular confinement systems made from high-density polyethylene (HDPE) that can be filled with different materials. They provide stability and strength to infrastructure, including wastewater treatment systems. Geocells can be used to create containment structures for wastewater treatment ponds, lagoons, and tanks, as well as to reinforce and stabilize slopes, embankments, and channels within the system. They also aid in filtration and help control erosion, making them a valuable component in wastewater treatment systems.

- Q: Can geocells be used for retaining walls?

- Yes, geocells can be used for retaining walls. They are lightweight, yet strong, and can be filled with soil or other materials to create a stable structure for retaining walls. Geocells provide excellent erosion control and can be easily installed and maintained.

- Q: Can geocells be used for bridge abutment construction?

- Yes, geocells can be used for bridge abutment construction. Geocells are flexible cellular confinement systems made of high-density polyethylene and can be filled with various materials like soil or granular materials. They provide stability and reinforcement to the soil, preventing lateral spreading and erosion. Therefore, they can be effectively used for constructing bridge abutments, ensuring a strong and durable foundation for the bridge.

- Q: Do geocells require any special permits for use in wetlands?

- Yes, geocells typically require special permits for use in wetlands as they involve altering the natural landscape and may have potential impacts on the ecosystem.

- Q: Are geocells suitable for use in ground reinforcement for solar farms?

- Yes, geocells are suitable for use in ground reinforcement for solar farms. Geocells provide effective ground stabilization, erosion control, and load distribution, making them an ideal solution for supporting the weight of solar panels and preventing soil erosion in solar farms.

- Q: How do geocells improve the performance of temporary access roads?

- Geocells improve the performance of temporary access roads by providing a stable and reinforced surface. They are made of a three-dimensional honeycomb structure that can be filled with various materials such as soil, gravel, or aggregate. This filling material locks into the cells, preventing it from shifting or eroding, even under heavy loads. This reinforcement increases the load-bearing capacity of the road, prevents rutting and erosion, and improves traction, making it suitable for heavy machinery and vehicles. Additionally, geocells distribute the load evenly, reducing stress on the underlying soil and minimizing the need for maintenance or repairs.

- Q: Can geocells be used in riverbank stabilization?

- Yes, geocells can be used in riverbank stabilization. Geocells are cellular confinement systems made of high-density polyethylene that can be filled with soil or other materials. They provide structural support and erosion control, making them suitable for stabilizing riverbanks and preventing soil erosion.

Send your message to us

Ultrasonic Geocell for Slope Pavers Slope Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords