Plastic Film Coated Aluminum Sheet Hot-sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Plastic Film Coated Aluminum Sheet Hot-sale

l Product Information

Aluminum sheet series 1xxx, 5xxx with good corrosion resistance and free from defects and no scratches, often used as raw material of billboard, building exterior decoration,kitchen sink,pieces of electronic, lighting components, giftware, reflectors and sheet metal processing, etc.

| ALLOY | TEMPER | THICKNESS (mm) | WIDTH (mm) | LENGTH (mm) |

| 1050, 1060, 1070, 1100 | O, H12, H14, H16, H18, H22, H24, H26, etc | 0.2-6.0 | 20-2000 | as required |

| 5052, 5754, 5083 | O, H18, H24, H32, H34, H111, H112, etc | 0.2-6.0 | 20-2000 | as required |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

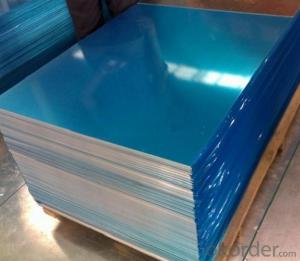

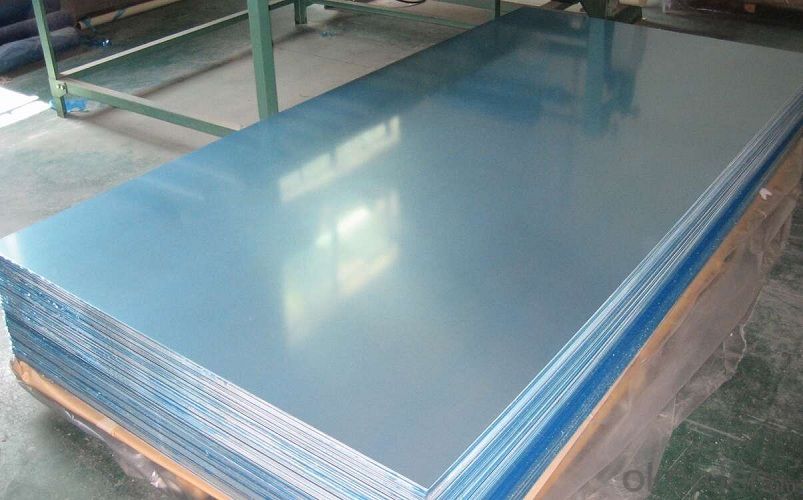

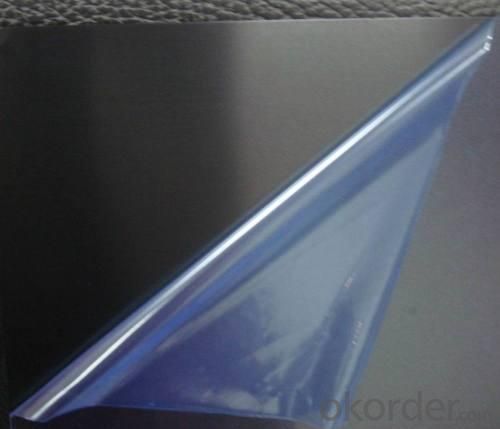

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: This question asks about the economic impact of aluminum coils, which are a key material in various industries.

- <p>Aluminum coils significantly impact the economy by driving growth in various sectors. They are vital in construction, automotive, aerospace, and packaging industries due to their lightweight, durability, and recyclability. The aluminum coil market stimulates manufacturing, job creation, and technological advancements. Additionally, their high demand supports the growth of the aluminum industry, influencing trade and contributing to GDP. The recycling of aluminum coils also reduces energy consumption and environmental impact, further benefiting the economy by promoting sustainable practices.</p>

- Q: What is an aluminum coil and what is it used for?

- An aluminum coil is a long, flat, and thin sheet of aluminum that is rolled up into a coil shape. It is typically made from high-quality aluminum alloys that are durable, lightweight, and corrosion-resistant. Aluminum coils have a wide range of applications across various industries. One of the most common uses is in the manufacturing of aluminum products, such as cans, containers, and packaging materials. The flexibility and malleability of aluminum coils make them ideal for shaping into different forms and sizes. Additionally, aluminum coils are extensively used in the construction industry for various purposes. They are commonly used for roofing, siding, gutters, and other exterior applications due to their ability to withstand harsh weather conditions and resist corrosion. The lightweight nature of aluminum coils makes them easier to handle and install, reducing labor and transportation costs. Moreover, aluminum coils are also used in heating, ventilation, and air conditioning (HVAC) systems. They are utilized in the production of condenser and evaporator coils, which are crucial components for controlling temperature and humidity in residential, commercial, and industrial buildings. In summary, an aluminum coil is a versatile and valuable material that finds widespread use in numerous industries. Its lightweight, corrosion-resistant, and malleable properties make it an excellent choice for manufacturing aluminum products, as well as for construction and HVAC applications.

- Q: Can aluminum coils be used in the production of aluminum curtain walls?

- Indeed, aluminum coils possess the capability to be utilized in the fabrication of aluminum curtain walls. In the manufacturing procedure of aluminum curtain walls, it is customary to employ aluminum coils as the primary material. These coils are subjected to various processes, such as rolling, cutting, and shaping, in order to fashion the desired components of the curtain wall system. Due to its lightweight nature and resistance to corrosion, aluminum proves to be an optimal substance for curtain walls, as it imparts both structural stability and durability to the building facade, along with an appealing aesthetic. In essence, aluminum coils assume a vital role in the creation of aluminum curtain walls, guaranteeing the excellence and functionality of the end product.

- Q: What’s the loss rate per kg when processing aluminum coil to aluminum sheet?

- Weight=(0.8×1220×2440×2.7)/1000000=6.4kg

- Q: Is it safe and effective to use an electric stove to heat an aluminum coil?

- <p>Yes, you can use an electric stove to heat an aluminum coil. Aluminum is a good conductor of heat, so it will heat up when placed on an electric stove. However, it's important to ensure the coil is clean and free of any non-stick coatings that could be damaged by high heat. Also, be cautious of the temperature settings on your stove, as aluminum can melt at high temperatures. Always monitor the coil to prevent overheating or fire hazards.</p>

- Q: How are aluminum coils used in the production of aircraft components?

- Aluminum coils play a vital role in the manufacturing of aircraft components, offering a combination of strength, durability, and lightness that makes them ideal for this purpose. One primary application of aluminum coils in aircraft production involves fabricating sheet metal parts. Through techniques like rolling, stretching, and bending, these coils are transformed into flat sheets of aluminum, which are then cut and shaped to create wings, fuselage panels, and tail surfaces. The lightweight nature of aluminum makes it a preferred material for aircraft construction, as it reduces the overall weight of the aircraft and improves fuel efficiency and performance. Using aluminum coils allows manufacturers to easily produce thin and lightweight parts, contributing to the overall weight reduction of the aircraft. Additionally, aluminum coils are utilized in the production of structural components such as frames and beams. These coils are formed into extrusions, which are then cut and joined to create the structural elements of the aircraft. Aluminum's high strength-to-weight ratio makes it an excellent choice for these components, providing the necessary strength while keeping the aircraft's weight low. Apart from its structural applications, aluminum coils are also used in the production of various aircraft systems. For example, they are incorporated into the construction of heat exchangers, air conditioning units, and fuel tanks. Aluminum's excellent thermal conductivity allows for efficient heat transfer, which is essential for maintaining optimal operating conditions within the aircraft. Overall, aluminum coils are extensively utilized in the manufacture of aircraft components due to their lightweight nature, high strength, and excellent thermal properties. Their versatility and the ability to be processed into different shapes and sizes make them the preferred material for manufacturing critical aircraft parts, ensuring the safety, performance, and efficiency of modern aircraft.

- Q: Is there any legislation or regulation governing the use of aluminum coils within specific industrial sectors?

- <p>Yes, there are regulations on using aluminum coils in certain industries. These regulations often vary by country and industry. For instance, in the food and beverage industry, aluminum coils may be subject to food safety standards to ensure they do not contaminate products. In construction, they might need to meet building codes and specifications for strength and durability. The aerospace industry has stringent regulations regarding the materials used in aircraft parts, including aluminum coils. Compliance with these regulations is crucial to ensure safety, quality, and to avoid legal penalties.</p>

- Q: How are aluminum coils used in rainwater harvesting systems?

- Rainwater harvesting systems commonly use aluminum coils due to their durability and effective heat transfer properties. These coils are typically installed inside rainwater storage tanks and connected to a heat exchanger system. The main purpose of aluminum coils in rainwater harvesting systems is to facilitate the heating or cooling of stored rainwater, depending on its intended use. For example, if the harvested rainwater is meant for domestic use like showers or laundry, the aluminum coils can effectively heat the water to the desired temperature. Conversely, if the harvested rainwater is intended for cooling purposes such as air conditioning or industrial processes, the coils can also efficiently cool the water. The design of the aluminum coils maximizes the surface area exposed to the rainwater, enabling efficient heat transfer. This allows the coils to quickly absorb or release heat based on the system's requirements. Aluminum is chosen as the material for these coils due to its high thermal conductivity, corrosion resistance, and lightweight nature. Furthermore, the coils also aid in preventing the growth of bacteria and algae within the rainwater storage tanks. Aluminum possesses natural antimicrobial properties that hinder the growth of these organisms, ensuring that the collected rainwater remains clean and safe for use. In summary, aluminum coils are essential components in rainwater harvesting systems as they enhance the usability of collected rainwater through efficient heat transfer and maintenance of water quality.

- Q: Can aluminum coils be painted?

- Yes, aluminum coils can be painted. However, it is important to follow proper surface preparation and use a suitable paint that is compatible with aluminum to ensure a long-lasting and durable finish.

- Q: Is it possible to use a saw to cut aluminum coils?

- <p>Yes, aluminum coils can be cut with a saw, but it's important to use the right type of saw. A hacksaw or a fine-toothed metal cutting saw is suitable for cutting aluminum. Lubrication is also crucial to reduce friction and prevent the saw blade from overheating. When cutting aluminum, it's advisable to use a cutting fluid or a light machine oil to keep the blade cool and ensure a clean, smooth cut. Always follow safety precautions and wear appropriate protective gear when cutting metal.</p>

Send your message to us

Plastic Film Coated Aluminum Sheet Hot-sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords