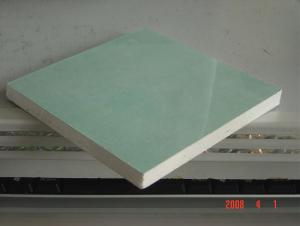

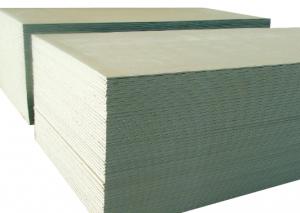

Gypsum Board in Size 2440*1220*12mm for Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 700 pc

- Supply Capability:

- 120000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Main Material: Gypsum Powder

Normal size: 2440x1220mm, 2400x1200mm

Normal thickness: 7, 8, 8.5, 9, 9.5,10, 12, 13, 15mm

Edge: Square, Tappered

Category: Regular, Fire resistant, Moistureresistant, Water proof

Performance: Fire-resistance, Moisture-resistance,Water-proof, Heat-preventing

Specifications:

1) Sepcial healthy breath function

2) Cost effective and more reliable, easy to install

- Q: I'm having the kitchen done and are having plasterboards put up 'cos the plaster that is on at the moment is so old, dry and flaking off in large peices. Just wondered if these walls will be strong enough to hold up my wall units. Pleeeeeaaase let me know.

- plasterboards (AKA drywall, sheetrock) are not very strong, definitely not strong enough to hold kitchen cabinets by themselves. be sure that when you hang things like cabinets, shelves, etc from the wall that they are anchored to the studs and the frame of the house or else they will just tear out.

- Q: can i wallpaper over a plasterboard?

- Mandantory to have a good primer coat on clean plasterboard first. Dry. Wallpaper away.

- Q: I have some old style plasterboard in my house and I was wondering if there is any good way to smooth it out so it matches my new drywall? I'd rather not have to take it down but if it comes to that i'll do it. I am going to be texturing the new drywall. Could I just spray the texture on the old stuff and maybe hide it enough to get by?thxJoe

- You may beed to sand the rough area before texturing, hammer in nail heads and patch.

- Q: The mirror is about 75cm wide and 50cm high. Can it be hung on a plasterboard wall? What type of screws or nails do I need?

- There are some large mirror that can stand on their own. For a plasterwall, you need something real strong and you need something to be at the bottom of the mirror, supporting it.

- Q: I had some water damage to the ceiling of a small bathroom and need to remove the plaster, but I don't want to invest in a reciprocating saw (plus they're scary to use overhead).

- 1

- Q: it is always a dry wall

- Liquid Nails makes a specific drywall adhesive.... which should work...as long as you think you'll NEVER have to remove that drywall for any reason. If this is a below grade wall.... do yourself a favor....don't glue drywall to the brick.

- Q: Can the paint be sprayed on the wall, gypsum board?

- Wall and gypsum board, after the batch of putty sandpaper processing, you can spray paint.

- Q: What areas in a house will require fireline plasterboard? I think it needs to be used on walls around a fireplace but im not sure. If you know of any other areas please answer

- Check your local building and fire codes. Varies from area to area and country to country.

- Q: Haha, my Mum wants to know. Can you use Stud Adhesive? Or is there something else you must use?Thanks heaps!

- you dab the wall with plaster board adhesive.mix to a thick consistency.dab is method of flicking the adhesive on to the wall with a trowel.and firmly smack the board with a straight edge (long spirit level or a piece of wood) from one corner to the Other that makes sure the board goes on firmly and level

Send your message to us

Gypsum Board in Size 2440*1220*12mm for Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 700 pc

- Supply Capability:

- 120000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords