PHC Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

We mainly engaged in manufacturing PHC concrete piles with diameters of Φ600~Φ1400 for wharf. Every year, the company produces various types of concrete piles of over 150,000 meters with single-section pile of 41meter long and annual gross output value up to RMB 600 million.

With years’ manufacturing experience of concrete piles and a great number of excellent technological and management talents, the company persists in technical innovation and research of new products. The large-diameter PHC concrete piles with merits such as good bending strength, large bearing capacity, fine resistance against the external force and so forth have been the preferential choice of structural materials for foundation engineering construction such as large ports, wharfs, shipyard, huge bridges, high-rise buildings, heavy factories, high-speed railway, etc.

The company holds the operation philosophy of “honest, practical and harmonious for win-win” and persists in the quality guideline of “constant improvement with prohibition of non-conforming products into construction site” to provide you sincerely with superior products and service.

Detailed introduction to PHC PILE:

PTC C70

Φ400 X 70mm ≤12m

Φ500 X 80mm ≤13m

Φ550 X 80mm ≤13m

Φ600 X 80mm ≤13m

PC or PHC(C70 A or C80 AB)

Φ400 X 90mm ≤14m

Φ500 X 100mm ≤15m

Φ500 X 120mm ≤15m

Φ500 X 125mm ≤15m

Φ550 X 100mm ≤15m

Φ550 X 120mm ≤15m

Φ600 X 110mm ≤15m

Φ600 X 130mm ≤15m

- Q: What are the characteristics of different tin process

- Good mechanical properties: tinplate cans relative to other containers, such as plastic, glass, paper containers and strength, and good rigidity, it is not easy to break. It is not only used for small sale packing, but also the main container for large transportation package. 2.: excellent barrier tin barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products.

- Q: Can Steel H-Beams be used in foundation or basement construction?

- Yes, steel H-beams can be used in foundation or basement construction. These beams are commonly used to provide structural support and stability to the foundation or basement walls. They offer high strength and durability, making them suitable for withstanding heavy loads and ensuring the structural integrity of the building.

- Q: Are there any alternatives to steel rebars?

- There are multiple options available instead of steel rebars. One such option is the utilization of fiber-reinforced polymer (FRP) rebars, which consist of high-strength fibers embedded in a polymer matrix. FRP rebars present various advantages over traditional steel rebars, such as resistance to corrosion, high tensile strength, and lightweight characteristics. Moreover, they are non-magnetic and electrically non-conductive, making them appropriate for areas with concerns regarding electromagnetic interference. Another alternative is the employment of basalt rebars, which are manufactured from fibers derived from basalt rock. Basalt rebars offer similar benefits to FRP rebars, including corrosion resistance and high tensile strength. Furthermore, certain manufacturers have developed alternative materials like bamboo, carbon fiber, and glass fiber rebars, which have also displayed potential in specific applications. Nevertheless, it is crucial to consider that the selection of alternative rebars depends on the specific requirements of a project, and factors like cost, availability, and adherence to local building codes should be taken into account when choosing an alternative to steel rebars.

- Q: What are the common uses of ferritic stainless steel?

- Ferritic stainless steel is commonly used in various applications where corrosion resistance, heat resistance, and magnetic properties are required. Some common uses include automotive exhaust systems, kitchen appliances, architectural and decorative applications, food processing equipment, and industrial equipment such as tanks, pipes, and valves.

- Q: What is the average thickness of galvanized steel sheets?

- The average thickness of galvanized steel sheets typically ranges from 0.8mm to 3mm, depending on the specific application and industry standards.

- Q: How are steel strips used in the manufacturing of electrical equipment?

- Steel strips are commonly used in the manufacturing of electrical equipment as they provide structural support, magnetic shielding, and heat dissipation capabilities. They are used for making transformer cores, motor laminations, and inductive components due to their high magnetic permeability and low electrical resistance. Additionally, steel strips are utilized for creating sturdy enclosures and mounting brackets that ensure the durability and proper functioning of electrical equipment.

- Q: Hey Guys, I'm planning on purchasing a bmx bike and I have been recommended by many people the Kink Launch 2012. I'm thinking of getting it but the frame is made from High Tensile steel and I know the chromoly is stronger and more expensive, but I plan to use my bmx just to chill, ride with friends and some times go through dirt trails at my park, I would like to know, how strong Hi Tensile steel is and can it handle jumps not massive jumps but like jumps where you get like 3 feet high (1m) just for fun, I might go to the skate park but I'm not gonna do tail whips and massive jumps, I just want it as a mobile piece of transportation. I don't want to buy a mtb because I already had 3 of them and they are not practical to take with you on holidays.So, do you think the Kink Launch 2012 is good enough or should I cough up an extra $80 and get the gap ($500 AU)? As I said I ain't gonna do huge jumps.

- High tensile steel could mean almost anything. SAE 4130 Chrome-Moly steel is the de-facto standard for steel bikes frames. High tensile steel could actually mean the same thing since chrome-moly is classified as high strength steel. The strength of the frame depends as much on the quality of the welds and on the size/thickness of the tubing as much as anything else. I'd say what kind of steel you use makes only a minor difference. One reason you want to buy bikes from reputable name-brand companies is they tend to have strict quality controls, this is particularly important when it comes to welds. Welds are always the weakest part of any bike frame, don't let anyone tell you different. 99% of the time if something in the frame breaks, it'll be at the welds. hope this helps.

- Q: How are stainless steel sheets used in the construction industry?

- Stainless steel sheets are extensively used in the construction industry due to their remarkable properties and versatility. These sheets are mainly utilized for their durability, corrosion resistance, and aesthetic appeal. One of the primary applications of stainless steel sheets in construction is for roofing and cladding purposes. They are commonly used for roof panels, wall panels, and façade systems. Stainless steel sheets provide excellent protection against weather elements, such as rain, snow, and UV rays. They also offer resistance to corrosion, ensuring the longevity of the building's exterior. Additionally, stainless steel sheets are frequently employed in the construction of architectural structures like bridges and tunnels. Their high strength-to-weight ratio makes them suitable for such applications. Stainless steel sheets can withstand heavy loads and provide reliable support, ensuring the structural integrity of these infrastructures. Moreover, stainless steel sheets are utilized in the construction of interior components, such as elevator doors, escalators, and handrails. Their sleek and modern appearance adds a touch of elegance to the overall design. These sheets are also hygienic and easy to clean, making them ideal for applications in hospitals, laboratories, and food processing facilities. In summary, stainless steel sheets play a crucial role in the construction industry. They are used for roofing, cladding, architectural structures, and interior components. With their exceptional durability, corrosion resistance, and aesthetic appeal, stainless steel sheets contribute to the longevity and aesthetic value of various construction projects.

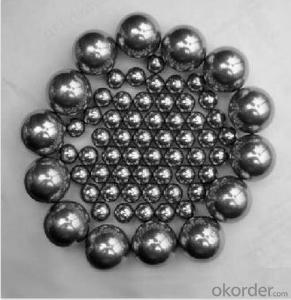

- Q: Can stainless steel balls be used in centrifugal pumps?

- Yes, stainless steel balls can be used in centrifugal pumps. They are commonly used as bearing balls or seal balls in centrifugal pumps due to their corrosion resistance, durability, and ability to handle high-speed rotations.

- Q: How do steel rebars distribute loads in concrete structures?

- The reinforcement and increased tensile strength provided by steel rebars allow for the distribution of loads in concrete structures. A grid-like pattern is typically used to place the rebars in the concrete, creating a network of support throughout the structure. This network helps evenly distribute external loads, such as the weight of the building or the force of an earthquake, preventing the concrete from cracking or failing under stress. To effectively distribute loads, the rebars transfer tensile forces to the surrounding concrete. While concrete is strong in compression, it is weak in tension. The rebars act as reinforcement, resisting the tensile forces and preventing cracks in the concrete. When a load is applied to the structure, the rebars bear a portion of the load and distribute it to adjacent rebars and the surrounding concrete, increasing the overall strength and stability of the structure. The spacing and diameter of the rebars also influence load distribution in concrete structures. Proper spacing ensures even distribution of the load, minimizing the risk of localized stress concentration. The diameter of the rebars is also important, as larger diameter rebars can withstand higher loads and provide more reinforcement. In addition to load distribution, steel rebars help control crack propagation in the concrete. When cracks occur, the rebars transfer stress around the cracked area, preventing them from spreading and maintaining the structural integrity of the concrete. In summary, steel rebars are essential for distributing loads in concrete structures. They provide reinforcement, increase tensile strength, and control crack propagation. Proper placement and sizing of the rebars ensure even load distribution, enhancing the durability and longevity of the structure.

Send your message to us

PHC Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords