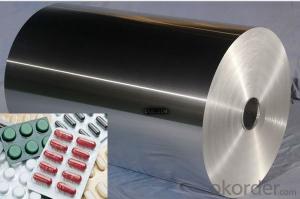

Pharmaceutical Aluminum Foil Lids with Heat sealing lacquer for medical tablet Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

Aluminum Foil Lid

Embossed aluminum foil lids

Die cut piece

Used for sealing PP, PS,PE cups.

Packing for yogurt, milk et

Aluminum Foil Heat Seal Lid for Coffee

Die cut sizes: as client's request

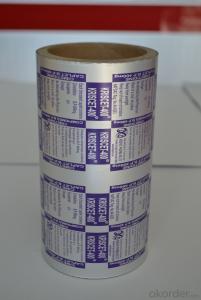

Printed: 1-10 colors

Foil thickness: 30-50 micron

Embossed aluminum foil lids are used for sealing PP, PS,PE cups.

Aluminium lidding foil for yogurt,cheese,juice,beverage cups

Properties:Peelable.Meet with FDA or SGS requirments

Lid structure

| 1, aluminum foil /PP lacquer (common) 2, aluminum foil /PS lacquer (common) 3, Al/Heat seal layer 4, PET/AL/Heat seal lacquer |

Embossing | Worm embossing Pin dot embossing |

Thickness of Aluminum foil | From 30 micron to 50 micron |

Heat Seals: | PP and PS tubs PE, PVC, PET also Paper cups |

Lid Diameters (mm)

| 37, 48, 59, 60, 61, 62, 65,68, 72, 73.5,74, 75.5, 76, 79,81,88,89, 90, 91,95.3, 98, 108,118,121 etc We also make square lids: 63*63, 75*150, 90*130, 61*141, 93.5*93.5,120*120, etc We have more than 100 sharps die cut mold for your choice. |

Printing | Rotogravure 1-10 colors |

Product: | Yogurt, milk, ice cream; butter; jelly Juice, Water, Jam, Dry food, dessert, coffee etc |

- Q: How do 101 aluminum sheets compare in terms of strength and durability?

- 101 aluminum sheets are known for their excellent strength and durability properties. They offer a high level of resistance to corrosion, making them suitable for various applications in industries such as automotive, construction, and aerospace. Additionally, their strength-to-weight ratio is impressive, allowing for efficient use in structures where weight reduction is essential. Overall, 101 aluminum sheets are considered strong and durable materials with a wide range of practical uses.

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets can be used in aerospace industries. Aluminum is commonly used in the aerospace industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used for various applications such as aircraft structures, wings, fuselages, and skins.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it a popular choice for constructing bus bodies. Its high strength-to-weight ratio allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum can be easily molded and shaped, enabling manufacturers to design buses with unique and modern aesthetics.

- Q: Is it feasible to utilize aluminum sheets in constructing carports and garages?

- <p>Yes, aluminum sheets can be used for carports and garages. They are lightweight, durable, and resistant to corrosion, making them a popular choice for outdoor structures. Aluminum sheets are also easy to install and maintain, and they can be designed to withstand various weather conditions. However, it's important to consider the thickness and quality of the aluminum to ensure it can bear the weight and withstand potential damage from weather elements.</p>

- Q: the coil is wrapped around the aluminium pipe will it effect the efficiency of the coil gun ?

- Hopefully yes.

- Q: Are aluminum sheets fire resistant?

- Aluminum sheets are in fact fire resistant. Aluminum has a high melting point and does not ignite or burn easily. It is a non-combustible material, meaning it does not contribute to the spread of fire. Aluminum sheets are often used in applications where fire resistance is important, such as in construction and aerospace industries. However, it is important to note that while aluminum itself is fire resistant, the materials or substances attached to or in contact with the aluminum sheet may not be fire resistant.

- Q: Can aluminum sheets be used for food processing equipment?

- Aluminum sheets are suitable for food processing equipment. The food industry favors aluminum for its many advantageous properties. It is lightweight, long-lasting, resistant to corrosion, and possesses excellent thermal conductivity. These attributes make aluminum sheets perfect for various applications in food processing equipment, including mixing bowls, cooking utensils, baking trays, and food storage containers. Furthermore, aluminum is non-toxic and does not interact with food, guaranteeing the safety and quality of processed products. Nevertheless, it is important to note that aluminum should not directly touch acidic or alkaline foods as it may react and impact the taste or quality of the food. In such instances, a protective barrier or lining should be employed. On the whole, aluminum sheets are extensively employed in the food industry due to their adaptability, durability, and food-safe characteristics.

- Q: Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- I've only found these type products online or at flea markets. It works quite well after a little practice.

- Q: Can you really block thermal imaging with glass or aluminum foil? If not, what can?

- Yes you can better with aluminum foil and somewhat little with glass. Thermal imaging takes a heat image based on an object radiating out more heat than it's background. The heat is all in the infrared so does not depend on visible light Aluminum foil is very effective in radiating back infrared waves, and very little infrared will pass thru the foil. Glass will let about 90 percent come thru, but it depends on the angle of incidence, with higher angles reflecting more infra red. But Stand in front of a window with the sun shining in, and you see how much infrared from the sun you can feel on your skin . Foil is probably about 95 % effective in reflecting infrared, depending on how shiny it is. In real life situations that is why the inside of thermos bottles are shiny aluminum (or silver) to reflect infrared heat, and fireman wear aluminum suits into fires to protect from the radiant heat ,which is the infrared. So if you wore an aluminized or silverized suit , a thermal imaging device would have a hard time seeing you from the background radiation given off by other objects. You have to give off more radiant heat than surrounding objects to be noticed by a thermal camera

Send your message to us

Pharmaceutical Aluminum Foil Lids with Heat sealing lacquer for medical tablet Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords