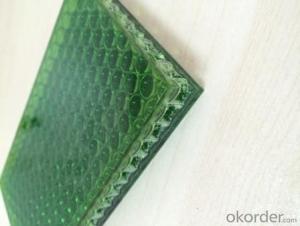

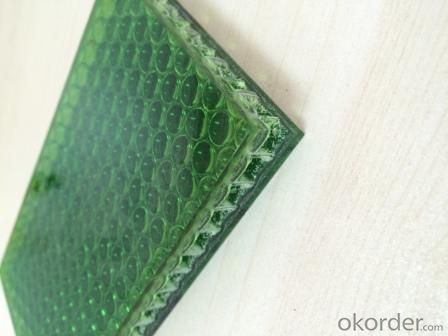

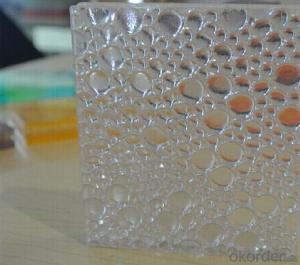

Plastic Sheets - PETG Waterdrop Honeycomb Decorative Panel with Polycarbonate Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PETG Waterdrop Honeycomb Decorative Panel with Polycarbonate Core

Features:

Light weight with high strenght, heat & sound insulation, low deformation and yellowing,

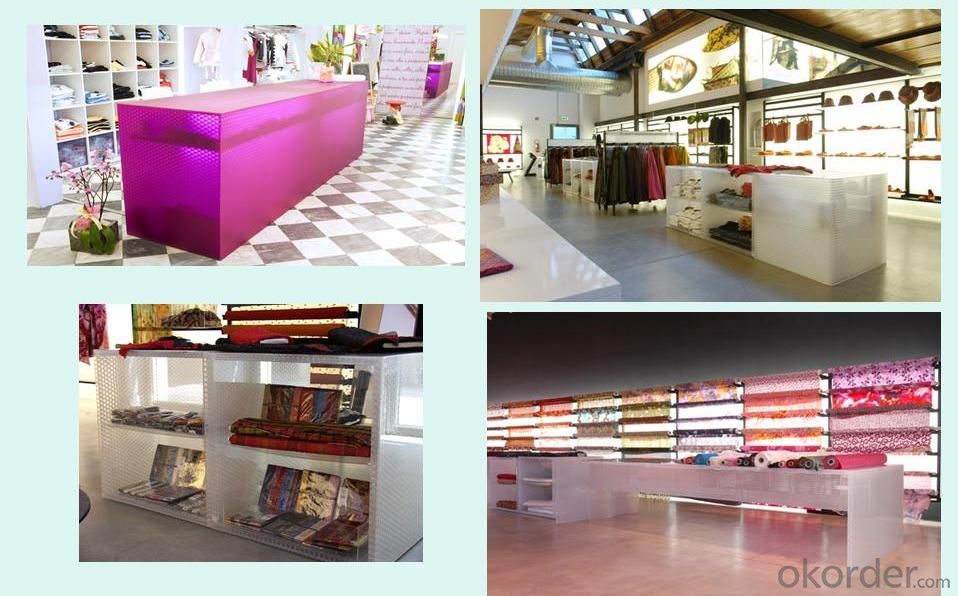

high shock resistance and compressive strength, environmental friendly and easy clean. It is widely

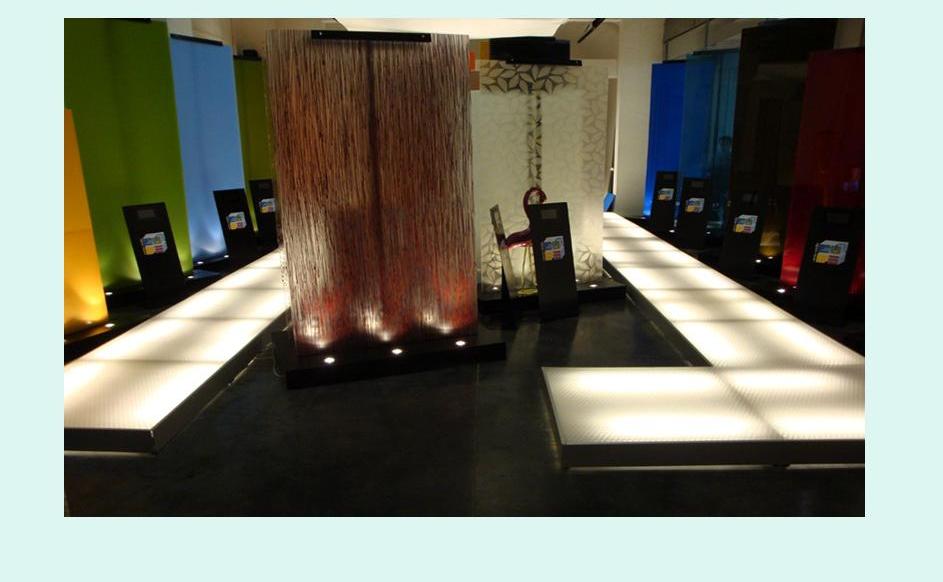

used for partitions, floors, suspended ceilings, table-boards,light boxes etc. in hotel, business space,bar, specialty store, villa, entertainment venue and so on. It is also applicable for indoor and outdoor places. Delicate and transparent, strong sense of art, interspersed water droplets bring a sense of peace and ice-cool. Interspersed like water droplets, clear and transparent, takes on a kind of water drop reflection effect under LED ligt. It’s incomparable amoung modern decoration materials, and it’s absolutely required material for interior and exterior slap-up building

Specification:

Materials: PETG

Honeycomb core: PC

Tubular Diameter:4,6,8mm

Aluminium Length of Side: 3-18mm optional

Fire Rating:B1 or C

Temperature Tolerance:-40-80 ℃

Standard Size:1200*2400mm

Special Size: 1200*3000mm

Panel Thickness: 1 - 6mm

Gauge:6-50mm

Color: Customized colors

Finish: Glossy or Satin

Application:

FAQ:

1. What materials do you use for your product?

For honeycomb Panel, we use Polycarbonate, Acyrlic, PETG to produce outer up and down panel, use

polycarbonate, Aluminum,Texture,plant and so on for Honeycomb Core or Interlayer

2. What if your payment term?

Generally, we accept L/C, TT, DA,DP payment term

3. Which port do you use and how long is your delivery time?

We are close to Shanghai Port and after receiving your down payment, we will arrange delivery within 25

days.

- Q: What are the environmental impacts of plastic sheets?

- Plastic sheets have several environmental impacts. Firstly, their production contributes to the depletion of fossil fuels and the emission of greenhouse gases. Secondly, plastic sheets are often not biodegradable and can persist in the environment for hundreds of years, leading to long-term pollution. Improper disposal of plastic sheets can result in litter, which can harm wildlife and marine ecosystems. Additionally, the extraction of raw materials for plastic sheets can lead to habitat destruction and biodiversity loss. Overall, the environmental impacts of plastic sheets highlight the urgent need for sustainable alternatives and proper waste management.

- Q: So I went to staples and had them laminate like 8 papers I HAVE to have laminated by tomorrow.... And I picked them up, came home, and they were literally my papers stuck between 2 plastic sheets. I can peel it easily and it is not sticking at all. Am I supposed to do something or did they mess up and forget something???? Please help!!!!

- It sounds like they messed up. My guess is that the machine was not hot enough to allow the laminate sheeting to bond. Yes, you should call them and go back. Laminating IS two plastic sheets with a paper between. However, when the machine is very hot, the plastic softens and bonds. Did you trim the papers? You should always leave a narrow edge of plastic around the edges, perhaps a quarter inch. If you trim it exactly against the paper, there is nothing on the edge to seal and bond. If they did the trimming, then check the edging. If there is a quarter edge beyond the paper and it is separating, then take it back. That could be a machine not hot enough. Take your receipt.

- Q: Can plastic sheets be used for safety windows?

- Yes, plastic sheets can be used for safety windows.

- Q: There is extreme wetness near the base of the walls 1 perticurally to the south and west and one to the north and west sides. I have had the attic ventilation balanced and it has gotten a little better. I also forgot that there is tyvek on the exterior and the cedar siding is curving toward the outside. I had the worst of it (siding) replaced this summer. The heat registers have just been replaced because they were rotted. I am replacing a sliding door for the same reason. I am also trying to replace some windows that may be leaking air. Thank you

- The plastic should be under the sheet rock and the insulation behind the plastic. The vapor barrier should go towards the heated finished side of the home. Your problem is the ceder shake siding that curves. I should always lay flat and over lap 6 to 8 inches. If you have any curving the water is getting behind them. Tyvek will not help this as there are tiny pin holes in it to allow the house to breath.

- Q: What are the different textures available for plastic sheets?

- There are several different textures available for plastic sheets, including smooth, matte, glossy, embossed, and textured.

- Q: Does anyone use rubber or plastic sheet on bed?

- when my brother comes to stay at my house i put one on the bed he uses as he has a weak bladder

- Q: Are plastic sheets resistant to staining from chemicals?

- Yes, plastic sheets are generally resistant to staining from chemicals.

- Q: Have seen many bands perform with their drummers in plastic boxes. Especially rock bands.

- i don't know, but that seems weird...

- Q: Can plastic sheets be used for DIY cutting boards?

- No, plastic sheets are not suitable for DIY cutting boards as they are prone to scratches and can harbor bacteria. It is recommended to use materials specifically designed for cutting boards, such as wood or food-grade plastic.

- Q: Can standard grade construction plastic sheeting be used as under layment for laminated flooring. Home Depot and Lowe's sell special black poly, and the cost is 4 times regular sheeting

- Check with the manufacturer, most have great websites that can answer your question. I've installed several types of laminate floors and always use a foam padding that has a coating already on it.

Send your message to us

Plastic Sheets - PETG Waterdrop Honeycomb Decorative Panel with Polycarbonate Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords