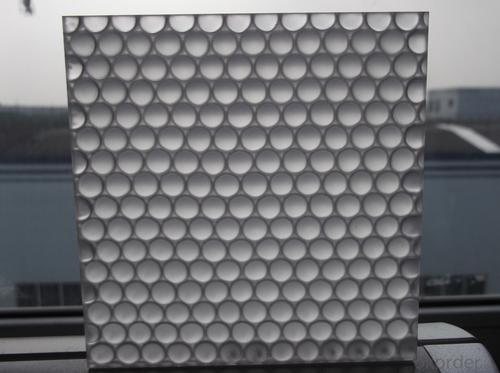

Plastic Sheets - Pmma Honeycomb Sheet with Aluminum Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PMMA Honeycomb Sheet with Aluminum Core

Features:

Light Weight with high strength, heat & sound insulation, low deformation and yellowing, high shock resistance and compressive strength, environmental protection and easy to recycle and clean.

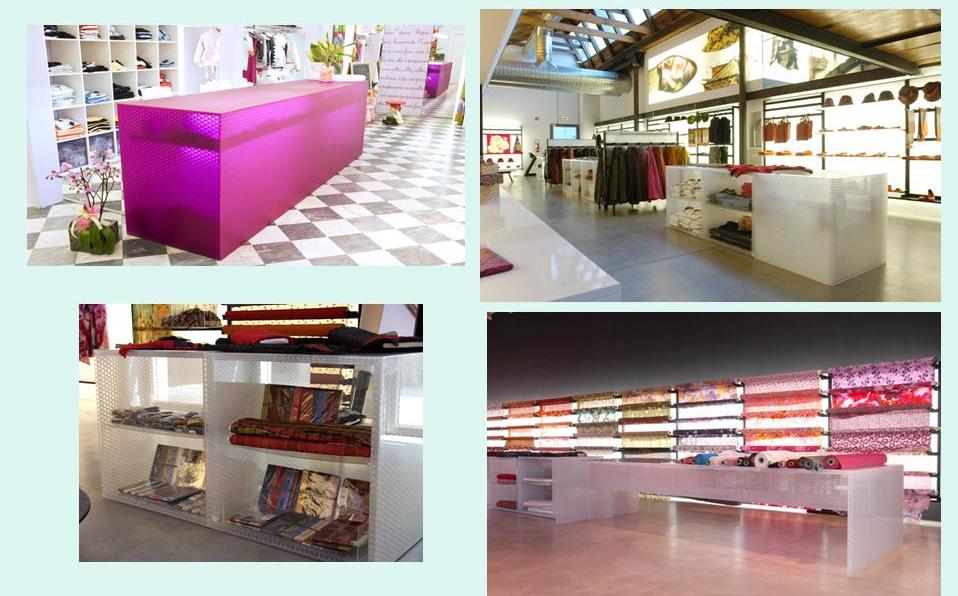

It is widely used for partition, floor, suspended ceilings, table-boards, light boxes etc. in hotel, KTV, business space, bar, specialty store, villa, entertainment venue and so on. It’s also applicable for indoor and outdoor places

Specification:

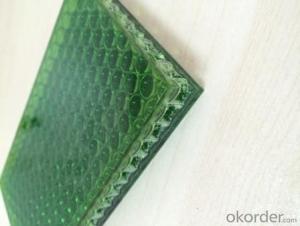

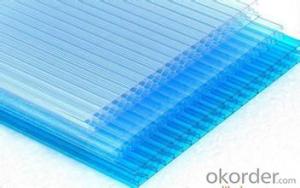

Materials: PC, PMMA, PETG

Honeycomb core: PC

Tubular Diameter:4,6,8mm

Aluminium Length of Side: 3-18mm optional

Fire Rating:B1 or C

Temperature Tolerance:-40-80 ℃

Standard Size:1200*2400mm

Special Size: 1200*3000mm

Panel Thickness: 1 - 6mm

Gauge:6-50mm

Color: Customized colors

Finish: Glossy or Satin

Application:

FAQ:

1. What materials do you use for your product?

For honeycomb Panel, we use Polycarbonate, Acyrlic, PETG to produce outer up and down panel, use

polycarbonate, Aluminum,Texture,plant and so on for Honeycomb Core or Interlayer

2. What if your payment term?

Generally, we accept L/C, TT, DA,DP payment term

3. Which port do you use and how long is your delivery time?

We are close to Shanghai Port and after receiving your down payment, we will arrange delivery within 25

days.

- Q: Does anyone have any suggestions?

- I like the two sided tape idea, and hate declawing a cat. Some chicken wire over the couch while you are not using it will protect it, but you have to carefully loop all the wire ends so they do not snag the couch. I am using oven racks on the benches outside to keep the cats off them. Window screens, anything that will catch their claws stop them. Get a scratching post or one of those cardboard scratching pads with catnip scent in it. I am not a cat person, but I love animals, really hate to see any cat declawed, as if it does get out or goes out, it cannot defend itself. Our little dog tore up a declawed cat, and I felt horrible about it. I did not know it had been declawed or I'd have reached in and pulled it away from the dog.

- Q: I want to make a pond for my turtles but I don't want to spend to much money on regular pond liner so I'm thinking about using black plastic sheeting instead. Is it good or bad? Is it too thin?

- Keep sunlight off the plastic. It isn't UV resistant. Line the bottom of the pond with sand or something. If the bottom slopes and the sand keeps running down the slope, then cut up burlap bags and cover it with the material.

- Q: Kitchen roof plastic buckle how to dismantle?

- The plastic material for the kitchen ceiling, because such materials need to use professional tools in the demolition, but accidentally damage the original structure or not in the decoration into the installation problems, therefore need to remove the professional staff of the demolition work, so to ensure the smooth completion of the decoration again.

- Q: We bought flannel sheets and are left with these lovely plastic packaging with the zipper on top. I would love some creative ideas to reuse them. Links would also be appreciated.

- I have used them to store my child's old baby blankets,pillows,clothes or even baby toys. They are a wonderful thing to use to store keepsake items.

- Q: Are plastic sheets suitable for outdoor furniture?

- Yes, plastic sheets are often suitable for outdoor furniture as they are weather-resistant, lightweight, and easy to clean.

- Q: Can plastic sheets be cut into custom shapes?

- Yes, plastic sheets can be cut into custom shapes using various cutting methods such as laser cutting, CNC routing, or even manual cutting with appropriate tools.

- Q: I've been working with a lot of humanitarian help lately, and have noticed that most mediocre plastic sheeting (tarpaulin) is blue whereas the good stuff is white or white on one side and black on the other. Why is most plastic sheeting blue? Is there any particular reason for this choice in color?

- 1) Blue is a color that contrasts most other natural colors in it's surroundings such as green grass and brown dirt, and therefore is found easily for cleanup. 2) Out of the colors they could use, blue is the cheapest to produce. Black, and surprisingly even white, costs more than blue die. This is because most raw plastic is a gray or multiple colors, so it takes more bleach to make it white than it does to just color it blue. Plus the materials necessary to create blue die are cheaper than most other colors. 3) Blue does not absorb as much heat as some other colors would, and therefore will keep it's integrity longer.

- Q: ...to the plants?

- No, it's totally ok I like that website! It has so many cheap things!

- Q: Are plastic sheets UV-resistant?

- Yes, plastic sheets can be UV-resistant.

- Q: Are plastic sheets resistant to warping from high temperatures?

- Yes, plastic sheets are generally resistant to warping from high temperatures. However, the exact level of resistance can vary depending on the type and quality of the plastic sheet.

Send your message to us

Plastic Sheets - Pmma Honeycomb Sheet with Aluminum Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords