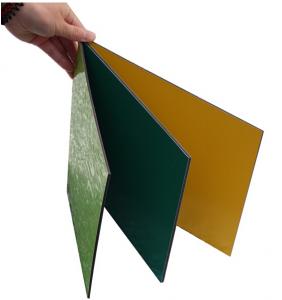

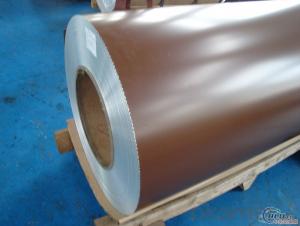

Aluminum Expanded Metal Sheets - PE PVDF Color Coated Aluminum for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Reflective sheet

Alloy or No.: Alloy

Alloy No.: AA1050, AA1060, AA1070, AA1070

Thickness: 0.2-3mm

Width: 10mm-2200mm

Length:10mm-2200mm

Tensile strength: ≥140N/mm2

Elongation: ≥2%(H26)

Yield Strength: ≥120N/mm2

Usage: Lights, grille lamp, tunnel lamp, solar collector etc.

1. Applications:

Furniture:Wardrobe, office equipment, cooking appliance

The transport industry:Automobile components, bicycle parts, body of railway coaches

Other:water tanks, enamel, barrels, tubes, chimney, grain barn, stamping, cable wrapper

2. Advantages:

Light-weight, high-strength, elegant and long-life, quake-proof, easy-installation, heat-insulated, colorful, anti-rust, water-proof, sound-insulated, etc

3. Our Company:

CNBM was established in November, 2005. We provide the annual output of 600,000 tons of zinc/alum-zinc, 600,000 tons of cold rolled sheets and 200,000 tons of color coated steel. Our main markets are Southeast Asia, the Middle East, Ireland, Italy, and Africa and South /NorthAmerica, Chile and other regions.

Our company focuses on hot-dipped galvanized steel coils, galvalume steel coil/sheet, PPGI/ PPGLsteel coil, corrugated/color-coating corrugated sheets.

Please provide the following information when placing an order:

1. Product name

2. Product standard

3. Material Grade

4. Specification

5. Zinc Coating

6. Surface treatment

7. Weight

8. Package requirements

if you show interestings on my products, you could contact with us.

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- In theory, yes, such as brazing.In fact, few people do that:Aluminum and steel systems do not form stable alloy remelting. Brazing is actually the use of third materials to link two original or dissimilar materials together. Unlike bonding, a stable alloy phase can be formed.

- Q: What is the difference between aluminium plate 5A05 and 5A06?

- The aluminum plate doesn't have this material. Have you made a mistake?Give you a full one,1, pure aluminum: Material: 1050/1060/1070/1100/ 1200/ thickness: 0.1---20mm width: 800---2200mm2, alloy aluminum: Material: 2A21/3003/5052/5083/6061/6082 /8011 thickness: 0.5---260mm width: 800---2800mm3 curtain wall Kaiping aluminum plate: Material: 1060/1100 thickness 0.95, 1.35, 1.85, 2.35, 2.7, 2.85mm, width 0.8---1.5m

- Q: This question asks for methods to guarantee that the edges of installed aluminum sheets remain straight and smooth.

- <p>To ensure that the edges of aluminum sheets are straight and smooth after installation, follow these steps: 1. Use high-quality aluminum sheets that are free from warping or defects. 2. Measure and cut the sheets accurately to avoid any discrepancies. 3. Use a sharp, clean cutting tool to prevent jagged edges. 4. Smooth out any rough edges with a file or sandpaper. 5. Install the sheets with precision, ensuring they are aligned properly. 6. Use appropriate fasteners and brackets to secure the sheets without causing any distortion. 7. Regularly inspect and maintain the sheets to address any issues promptly. By following these steps, you can maintain the straightness and smoothness of aluminum sheet edges after installation.</p>

- Q: I've narrowed down my next bike next year to either the cannondale Caad10 Ultegra version or the supersix 105 version, I've heard good things about both bikes, and at this point its gonna be down to preference after I ride it but, is aluminum stronger than carbon or vice versa? Will carbon crack easily or fail catastrophically?

- Carbon fiber and aluminum are newer and increasingly popular substitutes for the original bike frame material, steel. In the early 21st century, carbon fiber gained a reputation for being lightweight and the latest frame technology, but advancements in aluminum alloys and frame construction make the two frame materials equal contenders for best material. Almost all carbon fiber bicycles are designed for competitive road riders, who can get increased speed from riding on such a lightweight material. In contrast, aluminum frames are available for road, mountain, cyclocross, hybrid and other models of bikes as they come in different grades. Carbon fiber frames are not always lighter than aluminum frames. Weight depends on construction methods. According to outdoor equipment retailer REI, when it comes to bike frames, the more you pay, the less it weighs, and this holds true for carbon fiber and aluminum bikes. Compare two bikes of any frame material, and the lighter one will cost less. Due to the weight forces operating on a loaded-down touring bike, carbon fiber is a poor choice for such trips, as well as for any sort of off-road riding or trick riding. Lance Armstrong notes that the areas where metal fittings, such as fork ends, bottom bracket shells or headsets, attach to a carbon fiber frame are particularly weak. Carbon fiber is excellent for racing, with its combination of durability and weight. Aluminum frames handle better the weight and shocks of grocery shopping, commuting and trail riding.

- Q: What is an aluminum sheet?

- An aluminum sheet refers to a flat, thin piece of aluminum that is usually rectangular in shape. It is commonly used in various industries and applications due to its lightweight, durability, and corrosion resistance properties. Aluminum sheets can be easily manipulated, cut, and formed into different shapes to meet specific requirements in construction, automotive, aerospace, and manufacturing sectors.

- Q: Can aluminum sheet be used for architectural applications?

- Yes, aluminum sheet can be used for architectural applications. It is a versatile material that offers durability, lightweight properties, and corrosion resistance, making it suitable for various architectural projects such as facades, roofing, window frames, and decorative elements. Additionally, aluminum can be easily formed, fabricated, and finished to meet specific design requirements, making it a popular choice in the construction industry.

- Q: What are the necessary safety measures to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, it's crucial to wear appropriate personal protective equipment (PPE), including gloves to prevent cuts and eye protection to shield against flying debris. Ensure good ventilation to avoid inhaling dust or fumes from cutting or polishing. Use sharp tools to minimize the risk of accidents and always cut away from your body. Keep the work area clean and free of clutter to prevent slips or trips. Be cautious of electrical hazards if using power tools, and ensure all tools are properly grounded. Finally, be aware of the fire hazard potential of aluminum dust and store it safely away from ignition sources.</p>

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: What is the density of 101 aluminum sheets?

- The density of 101 aluminum sheets cannot be determined without knowing the dimensions and weight of each individual sheet.

- Q: I need to coat a piece of aluminum with aluminum oxide. Can I do it by just attaching aluminum to an electrode and put it into some water with the other electrode? I know you can make iron oxide that way, but will aluminum work? If it will work, which electrode should I put the aluminum on?

- This Site Might Help You. RE: Can you make aluminum oxide by electrolysis? I need to coat a piece of aluminum with aluminum oxide. Can I do it by just attaching aluminum to an electrode and put it into some water with the other electrode? I know you can make iron oxide that way, but will aluminum work? If it will work, which electrode should I put the aluminum on?

Send your message to us

Aluminum Expanded Metal Sheets - PE PVDF Color Coated Aluminum for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords