Aluminum Coil NJ - PE Prepainted Aluminum Coil for Gutters

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PE Prepainted Aluminium Coil for Gutters

PE Prepainted Aluminium Coil for Outdoor Gutters is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PE Prepainted Aluminium Coil for Gutters

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of PE Prepainted Aluminium Coil for Gutters

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PE Prepainted Aluminium Coil for Gutters

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PE Prepainted Aluminium Coil for Gutters

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

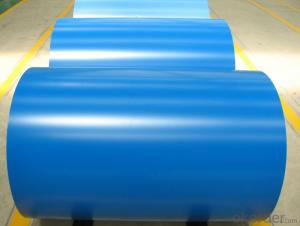

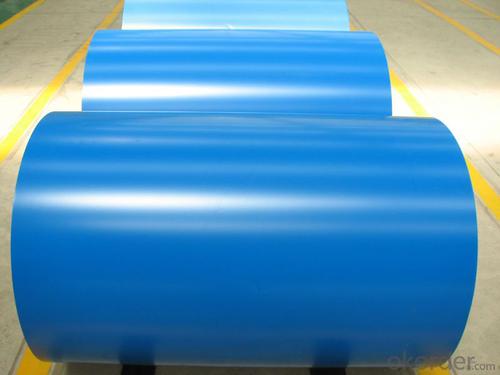

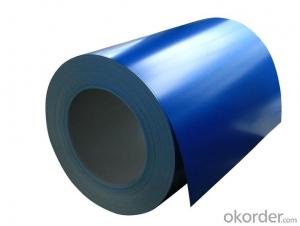

6. Image of PE Prepainted Aluminium Coil for Gutters

7. Package and shipping of PE Prepainted Aluminium Coil for Gutters

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different coil packaging sizes available for aluminum coils?

- The packaging sizes available for aluminum coils can vary depending on the specific needs and requirements of the customer. However, there are generally standard coil packaging sizes that are commonly available in the market. These sizes typically range from small to large, with varying dimensions and weights. Some of the common coil packaging sizes for aluminum coils include: 1. Small coils: These are typically used for smaller applications or projects. They usually have a diameter of around 200-300mm and a weight of approximately 50-150kg. 2. Medium coils: These coils are suitable for medium-sized applications and projects. They typically have a diameter of around 300-600mm and a weight of approximately 150-500kg. 3. Large coils: These coils are designed for larger applications or projects that require a greater amount of aluminum. They usually have a diameter of around 600-1200mm and a weight of approximately 500-2000kg. It's important to note that these are just general guidelines and the actual coil packaging sizes may vary depending on the manufacturer and specific requirements of the customer. Additionally, custom packaging sizes can often be requested to meet unique project needs.

- Q: Can aluminum coils be used for decorative purposes?

- Aluminum coils offer a multitude of possibilities when it comes to decoration. This versatile material can be easily molded and adjusted, making it ideal for a wide range of decorative uses. In industries like architecture, interior design, and automotive design, aluminum coils are frequently employed to create decorative trims, accents, and borders. To further enhance their visual appeal and match the desired aesthetic, these coils can be painted or coated with different finishes. Moreover, thanks to their lightweight nature and durability, aluminum coils are a popular choice for outdoor decorative purposes, such as garden ornaments, sculptures, and signage. Ultimately, incorporating aluminum coils into various projects provides a cost-effective and visually pleasing solution for adding decorative elements.

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a popular choice for coil materials in refrigeration systems due to its excellent heat transfer properties and corrosion resistance. Aluminum coils are lightweight, durable, and efficient in transferring heat, making them suitable for use in various refrigeration applications such as air conditioning units, refrigerators, and freezers. Additionally, aluminum coils are easier to shape and install compared to other materials, making them a preferred choice for manufacturers.

- Q: The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- a magnet can help to determine if it's steel, since brass isn't magnetic. as for aluminum, they'll have aluminum look to them, they never paint them to allow you to identify them, so silvery grey isn't what you're looking for. essentially, as long as the case isn't magnetic and isn't shiny grey, you should be fine. on a side note, I don't really understand why a gun range would forbid steel and aluminum cased ammo, unless they're trying to force the customers into buying the range's ammo instead of less expensive surplus or aluminum cased ammo. PS: Sirbobby, some ranges have a it touches the ground it's ours policy and they do strictly abide by it, if you pick up spent brass, they give you a warning and if you do it again, they throw you out and ban you from the range. they own the property and range and make the rules. I would always read their rules before applying for a membership or even going there.

- Q: Can aluminum coils be used in high-altitude environments?

- Yes, aluminum coils can be used in high-altitude environments. Aluminum is known for its lightweight and corrosion-resistant properties, which make it suitable for various applications, including those in high-altitude environments. Additionally, aluminum has a high strength-to-weight ratio, allowing it to withstand the challenges posed by high altitudes.

- Q: What are the common testing methods for aluminum coils?

- To ensure the quality and performance of aluminum coils, various testing methods are utilized. These methods encompass: 1. Visual inspection: A comprehensive examination of the coils is conducted to identify any visible defects like dents, scratches, or surface irregularities. This serves as an initial and fundamental step in the testing process. 2. Dimensional measurement: The dimensions of the aluminum coils are measured to verify if they meet the specified requirements. This involves assessing the length, width, and thickness of the coils. 3. Tensile testing: The mechanical properties of the aluminum coils, such as strength and elasticity, are evaluated through tensile testing. This procedure entails applying a tensile force to a sample of the coil until it fractures or deforms, enabling the determination of its tensile strength. 4. Hardness testing: The suitability of aluminum coils for specific applications is determined by assessing their hardness. Various methods, such as Rockwell or Brinell hardness tests, are employed to measure the coil's surface resistance to indentation or scratching. 5. Chemical composition analysis: The chemical composition of the aluminum coil is analyzed to ensure it meets the required specifications. Common techniques used for this analysis include spectroscopy or X-ray fluorescence (XRF) analysis. 6. Corrosion resistance testing: Due to exposure to harsh environmental conditions, it is crucial to assess the resistance of aluminum coils to corrosion. Tests such as salt spray testing or electrochemical impedance spectroscopy (EIS) are conducted to determine the coil's ability to withstand corrosion. 7. Coating quality assessment: If the aluminum coil is coated with a protective layer, testing methods such as adhesion testing, coating thickness measurement, or impact resistance testing are employed to ensure the quality and durability of the coating. These testing methods are commonly employed for aluminum coils. By conducting these tests, manufacturers can guarantee that the coils meet the required standards and perform optimally in their intended applications.

- Q: Some makes like KIA make a point of having aluminum engines. I thought this was for weight, but was more prone to failure, especially in a high mileage car.

- depends. i had a 79 F150, obviously engine made of steel. I let the water run out, the oil run out, the tranny fluid run out, etc. Couldnt kill that truck. I think the aluminum engines built today are fine, depending on the manufacturer. You cant run these engines into the ground though. I have had hondas and toyotas that ran forever with aluminum engines. Chrysler (dodge and plymouth) aluminum engines i have found are junk. I have been told by people who know to never buy a kia. if you can't afford a new car, buy a used one, like toyota, honda, never a nissan though. engines are just as good but the rest of the car is made out of pot metal. mazda is my favorite and many a ford has mazda engineering inside. the ford escape 4 cylinder is what i drive. it has a mazda engine.

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- How thick is the shaft? Even if it is solid, if it is fairly thin in order to be light weight like competition weapons I would not bet my life on blocking with something like that. If your shaft is solid and maybe one to 1 1/2 inches thick then maybe. A weapon does not have to be heavy to be powerful. If the practitioner is strong and fast he can generate quite a bit of power even with a lighter weight weapon. A bokken is not very heavy at all but in the hands of a skilled practitioner it can generate enough force to kill. The effectiveness of a weapon is in the technique not the weight. So don't underestimate a weapon and let weight fool you.

- Q: This question asks for methods to prevent rusting on aluminum coils during storage and transportation.

- <p>To prevent rusting on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Use a protective coating or wrapping to shield them from moisture and contaminants. Store the coils in a cool, dry place away from direct sunlight and corrosive substances. Avoid stacking them where they may come into contact with acidic materials. During transportation, secure the coils properly to prevent movement that could lead to scratches or damage. Use moisture-resistant covers to protect them from the elements. Regularly inspect the coils for signs of corrosion and address any issues promptly.</p>

- Q: My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- Aluminium is bad for you and too much aluminium can cause Alzheimer's disease and other problems. External deodorants are displaced by your perspiration and don't last long. Liquid chlorophyll is an internal deodorant that deodorises your body odours and perspiration odours before they come out of your pores. A table spoon of high strength liquid chlorophyll every day is all you need. Liquid chlorophyll also has a cooling effect so you perspire a bit less. You can find further information in a search for liquid chlorophyll + deodorant.

Send your message to us

Aluminum Coil NJ - PE Prepainted Aluminum Coil for Gutters

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords