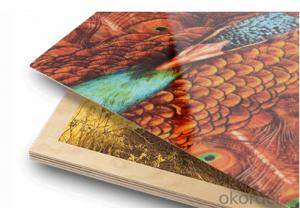

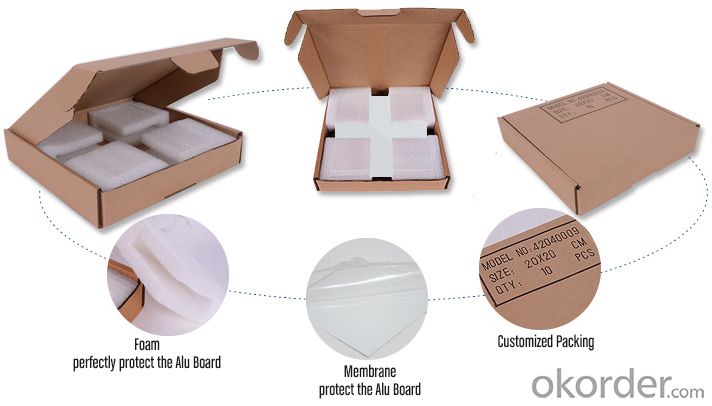

Painted Anodized Aluminum Sheets - Supplier Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

Free sample is OK

- Q: What are the different methods of surface coloring aluminum sheets?

- There are several methods of surface coloring aluminum sheets, including anodizing, powder coating, painting, and dye sublimation.

- Q: which has greater density 5 kg of lead or 10 kg of aluminum

- Pay attention to the terms in the questions! Under normal conditions, 5kg of lead has more density but less mass than 10kg of aluminum.

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- Aluminum okorder /

- Q: What are the different types of coatings available for aluminum sheets?

- There are several different types of coatings available for aluminum sheets, each offering unique properties and benefits. 1. Anodized Coating: Anodizing is a popular coating method that involves immersing the aluminum sheet in an electrolyte bath and passing an electric current through it. This process creates a durable and corrosion-resistant layer of oxide on the surface of the sheet. Anodized coatings can come in various colors and offer excellent abrasion resistance. 2. Powder Coating: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This coating method provides a durable, uniform, and attractive finish. Powder coatings are available in a wide range of colors and textures and offer excellent resistance to chipping, scratching, and UV fading. 3. Paint Coating: Aluminum sheets can also be coated with liquid paint. This method provides versatility in terms of color choices and finishes. Paint coatings offer good resistance to weathering, impact, and chemicals, but they may not be as durable as anodized or powder coatings. 4. Cladding: Cladding is a process in which a layer of a different metal, such as stainless steel or copper, is bonded to the aluminum sheet surface. This provides added protection, improved aesthetic appeal, and can enhance the sheet's mechanical properties. 5. Laminating: Laminating involves bonding a protective layer, such as a film or sheet, onto the surface of the aluminum sheet. This coating method offers protection against abrasion, UV rays, and chemicals, and can also provide decorative finishes. 6. Organic Coating: Organic coatings, such as polyurethane or acrylic coatings, are applied to aluminum sheets to provide protection against corrosion, weathering, and chemical exposure. These coatings offer flexibility, good adhesion, and a wide range of color choices. Overall, the choice of coating for aluminum sheets depends on the specific requirements of the application, such as durability, corrosion resistance, aesthetic appeal, and cost-effectiveness.

- Q: What are the different grades of aluminum sheets?

- The different grades of aluminum sheets include 1100, 3003, 5052, 6061, and 7075.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: Are aluminum sheets suitable for use as materials for windows and doors?

- <p>Yes, aluminum sheets can be used for windows and doors. They are known for their durability, low maintenance, and resistance to corrosion and weathering. Aluminum windows and doors are energy-efficient, lightweight, and offer excellent security. They can also be easily customized in terms of size and design, and are often used in modern architecture for both residential and commercial buildings.</p>

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

- Q: How does aluminum sheet perform in extreme temperatures?

- Due to its unique properties, aluminum sheet exhibits exceptional performance in extreme temperatures. One of its key advantages is its remarkable thermal conductivity, enabling it to efficiently transfer heat. This characteristic allows aluminum sheet to quickly adapt to extreme temperatures, preventing the occurrence of warping or cracking that may be experienced with other materials. Moreover, aluminum possesses a high melting point of approximately 660 degrees Celsius, rendering it highly suitable for usage in high-temperature environments. It remains structurally stable, retaining its strength and integrity even when subjected to intense heat. Additionally, aluminum exhibits a low coefficient of thermal expansion, resulting in minimal expansion and contraction in response to temperature fluctuations. This particular attribute enables aluminum sheet to maintain its shape and dimensions even when exposed to drastic temperature changes. Furthermore, aluminum showcases exceptional corrosion resistance, further augmented by the formation of a natural oxide layer on its surface. This oxide layer serves as a protective barrier against chemical reactions, safeguarding the aluminum from deterioration even in harsh environments or extreme temperatures. In conclusion, aluminum sheet demonstrates outstanding performance in extreme temperatures due to its high thermal conductivity, high melting point, low coefficient of thermal expansion, and excellent corrosion resistance. These properties establish it as a reliable choice for a multitude of applications, including the aerospace, automotive, and industrial sectors, where the ability to perform under extreme temperatures is of utmost importance.

Send your message to us

Painted Anodized Aluminum Sheets - Supplier Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords