Hot Rolled Aluminum Gutter Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

Hot Rolled Aluminum Gutter Coil CNBM Supplier is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

1. Temper: O, F, HXX

2. Thickness: Thickness

3. Width: 1000-1500mm

4. Type: Coil/Roll

5. Surface Treatment: mill finished

6. Application: Decoration, packaging, printing, covering

7. Standard size: Upon customer's demand

8. Quantity: 18tons(±10%)in one 20 feet container

l Product Description

Specification:

Hot Rolled Aluminium coil | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050, 1060, 1070,1100, 1235,1200, ,3003,3005, | O, F, H12, H18, H22, H24,H26,H32, H34, H36, H111, H112, H314 | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

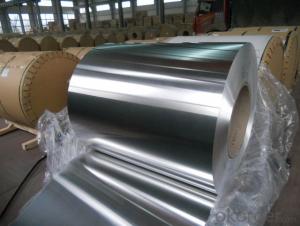

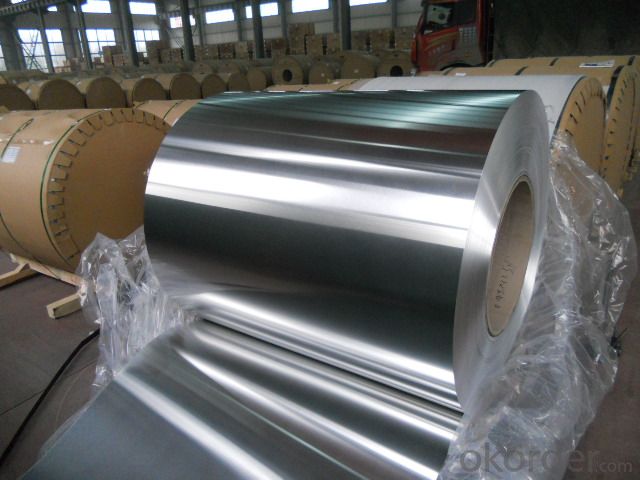

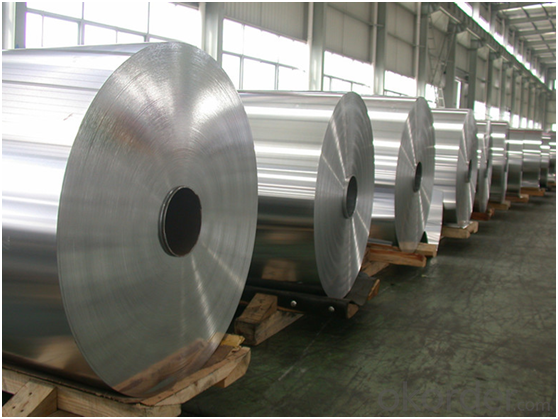

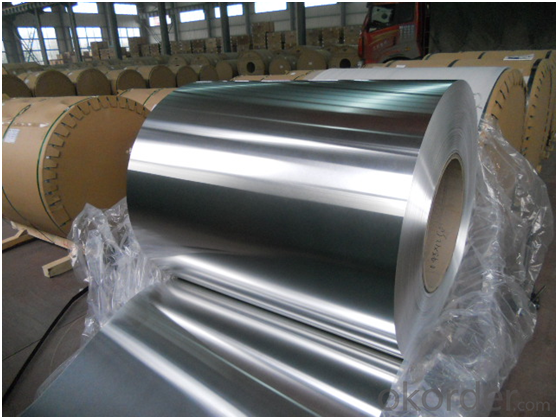

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q: Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be modified through various manufacturing processes to meet specific requirements and applications.

- Q: Are aluminum coils suitable for architectural roofing systems?

- Yes, aluminum coils are suitable for architectural roofing systems. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, which makes it easier to handle during installation and reduces the load on the building's structure. Additionally, aluminum is highly durable and corrosion-resistant, making it a long-lasting option for architectural roofing systems. It also has excellent thermal properties, reflecting heat and reducing energy consumption. Moreover, aluminum coils can be easily shaped and formed into various profiles and designs, allowing for flexibility in architectural styles. Lastly, aluminum is a sustainable material as it is recyclable, making it an environmentally friendly choice for roofing systems. Overall, aluminum coils are a suitable and practical option for architectural roofing systems, providing durability, versatility, and energy efficiency.

- Q: Is it safe and practical to use aluminum coils in cooking processes?

- <p>Aluminum coils can be used for cooking, but with certain precautions. They are commonly used in commercial kitchens for their heat conductivity and durability. However, for home cooking, it's important to avoid acidic or alkaline foods, as aluminum can react with them. Additionally, prolonged exposure to heat can cause aluminum to leach into food, which some studies suggest may have health implications. It's advisable to use aluminum cookware with a protective coating or opt for alternative materials like stainless steel or cast iron for health-conscious cooking.</p>

- Q: What are the different coil handling options available for aluminum coils?

- Some of the different coil handling options available for aluminum coils include coil lifters, coil tongs, coil hooks, coil cradles, coil upenders, and coil cars. These options allow for safe and efficient handling of aluminum coils during transportation, storage, and processing.

- Q: Are there any specific regulations or standards for aluminum coil production?

- Aluminum coil production is subject to specific regulations and standards that exist to guarantee the quality, safety, and sustainability of the process. The American Society for Testing and Materials (ASTM) International standard, specifically ASTM B209, is a crucial standard for aluminum coil production. This standard outlines the necessary chemical composition, mechanical properties, and technical requirements that aluminum coils must adhere to. Aside from ASTM standards, regulatory bodies like the International Organization for Standardization (ISO) and the Occupational Safety and Health Administration (OSHA) also establish regulations and standards. ISO 9001 is a widely recognized standard for quality management systems, while ISO 14001 focuses on environmental management systems. These standards provide guidance and requirements to ensure quality, environmental responsibility, and worker safety during the production process. Moreover, it's important to note that specific regulations may vary depending on the country or region. For instance, in the United States, the Environmental Protection Agency (EPA) oversees emissions and waste disposal related to aluminum coil production through the Clean Air Act and the Resource Conservation and Recovery Act (RCRA). These regulations aim to minimize the environmental impact associated with the production process. Overall, the purpose of these regulations and standards is to uphold the quality, safety, and environmental sustainability of the aluminum coil production industry. Manufacturers must comply with these regulations and standards to ensure that their products meet the necessary specifications and are produced in a responsible manner.

- Q: How are aluminum coils used in electrical applications?

- Due to their advantageous properties, aluminum coils find wide application in various electrical uses. Transformers, motors, and inductors are the primary domains where these coils are employed. Transformers utilize aluminum coils to facilitate the transfer of electrical energy from one circuit to another. These coils are wrapped around a magnetic core, thereby facilitating efficient energy transfer. Aluminum coils are preferred over copper coils in transformers due to their affordability, light weight, and superior conductivity. Moreover, aluminum coils exhibit higher thermal conductivity, enabling better heat dissipation. This feature is crucial for maintaining transformer efficiency and longevity. In motors, aluminum coils serve as the winding material for the stator, which is the stationary component of the motor. By passing an electrical current through the coils, a magnetic field is generated. This magnetic field interacts with the rotating magnetic field produced by the motor's rotor, resulting in motor rotation. Aluminum coils are favored in motors due to their lightweight nature, contributing to overall motor efficiency by reducing its weight. Inductors, another electrical component, employ aluminum coils. Inductors store electrical energy in the form of a magnetic field. When an electric current traverses the coil, a magnetic field is generated, which opposes changes in the current. Aluminum coils are utilized in inductors owing to their high electrical conductivity, facilitating efficient energy storage and release. In summary, aluminum coils are extensively used in electrical applications due to their cost-effectiveness, lightweight nature, excellent conductivity, and high thermal conductivity. Their application in transformers, motors, and inductors plays a pivotal role in ensuring efficient and reliable operation of electrical systems.

- Q: What are the potential health hazards linked to the use of aluminum coils?

- <p>There are concerns about the use of aluminum coils due to the possibility of aluminum leaching into food during cooking. Aluminum has been linked to various health issues, including cognitive decline and Alzheimer's disease, although the evidence is not conclusive. Additionally, aluminum exposure may lead to bone and neurological disorders. However, the health risks associated with aluminum coils are still a subject of debate among researchers. It's recommended to minimize exposure to aluminum by using alternative cooking methods or materials, such as stainless steel or cast iron.</p>

- Q: Are there any specific certifications or qualifications required for aluminum coil suppliers?

- Yes, there are specific certifications and qualifications that are important for aluminum coil suppliers. One of the key certifications for aluminum coil suppliers is the ISO 9001 certification, which ensures that the supplier has implemented a quality management system and meets the international standards for quality. This certification indicates that the supplier has effective quality control processes, consistent product performance, and customer satisfaction. Another important qualification for aluminum coil suppliers is the AS9100 certification, specifically for suppliers serving aerospace industries. This certification ensures that the supplier has met the quality management system requirements specific to the aerospace industry, including stringent quality control, traceability, and compliance with industry standards. Additionally, aluminum coil suppliers may also need to comply with specific industry standards such as the American Society for Testing and Materials (ASTM) standards or the European Union's REACH regulations for chemical substances. These standards ensure that the supplier's products meet the required specifications and are safe for use in various applications. Furthermore, some aluminum coil suppliers may possess specialized certifications or qualifications related to specific industries or applications. For example, suppliers serving the automotive industry may hold certifications such as the International Automotive Task Force (IATF) 16949 certification, which demonstrates their ability to meet the demanding requirements of automotive manufacturers. Overall, while specific certifications and qualifications may vary depending on the industry and application, aluminum coil suppliers should have certifications such as ISO 9001 and industry-specific certifications to ensure their products meet the required quality standards and comply with relevant regulations.

- Q: How do aluminum coils contribute to sustainable manufacturing?

- Aluminum coils contribute significantly to sustainable manufacturing in various ways. Firstly, aluminum is a highly recyclable material, and the use of aluminum coils promotes a closed-loop recycling system. These coils can be easily melted down and reused without losing their original properties, reducing the need for new raw materials and minimizing the environmental impact of mining and extraction. Additionally, aluminum coils are lightweight, which reduces energy consumption during transportation. Their lightweight nature makes them more fuel-efficient to transport, resulting in lower greenhouse gas emissions. This not only reduces the carbon footprint but also saves costs associated with transportation. Moreover, aluminum has excellent corrosion resistance properties, which makes it durable and long-lasting. This durability reduces the need for frequent replacements, leading to less waste generation. It also extends the lifespan of products that use aluminum coils, reducing overall resource consumption and minimizing environmental strain. Furthermore, the use of aluminum coils in manufacturing processes promotes energy efficiency. Aluminum has high thermal conductivity, meaning it can efficiently transfer and dissipate heat, resulting in reduced energy consumption during various manufacturing operations. This energy efficiency translates into lower energy costs and reduced greenhouse gas emissions. Lastly, aluminum is non-toxic and does not release harmful substances during its lifecycle. This ensures the safety of workers, consumers, and the environment. The absence of toxic materials also simplifies the recycling process, making it easier and more environmentally friendly. In conclusion, aluminum coils contribute to sustainable manufacturing through their recyclability, lightweight nature, durability, energy efficiency, and non-toxic properties. By incorporating aluminum coils into manufacturing processes, companies can reduce their environmental impact, conserve resources, and promote a more sustainable future.

- Q: What are the factors that affect the price of aluminum coils?

- The price of aluminum coils can be affected by various factors. One of the main factors is the global supply and demand for aluminum. In the case of an aluminum shortage, the price of aluminum coils is likely to rise. Conversely, if there is an excess supply of aluminum, the price may decrease. Another factor that can impact the price of aluminum coils is the cost of raw materials. Aluminum is obtained from bauxite, and the cost of mining and extracting bauxite can fluctuate depending on factors such as labor expenses, energy prices, and government regulations. Any changes in these factors can affect the overall production cost of aluminum, which in turn can influence the price of aluminum coils. Transportation expenses also play a role in determining the price of aluminum coils. Aluminum is often transported over long distances, and the cost of shipping or trucking can vary based on fuel prices, distance, and other logistical factors. Higher transportation costs can contribute to the overall price of aluminum coils. Currency exchange rates can also have an impact on the price of aluminum coils. Aluminum is traded on global markets, and fluctuations in exchange rates can affect the cost of importing or exporting aluminum. If the currency in which aluminum is traded strengthens against other currencies, the price of aluminum coils may increase. Lastly, market competition can influence the price of aluminum coils. When there are multiple suppliers of aluminum coils, they may compete with each other to attract customers. This competition can result in price fluctuations as suppliers try to offer competitive prices to secure buyers. To sum up, the price of aluminum coils can be influenced by factors such as global supply and demand, the cost of raw materials, transportation costs, currency exchange rates, and market competition. Understanding these factors can help businesses and consumers anticipate and respond to changes in the price of aluminum coils.

Send your message to us

Hot Rolled Aluminum Gutter Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords