Out Decking/WPC/ Wood Plastic Composite DIY Floor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

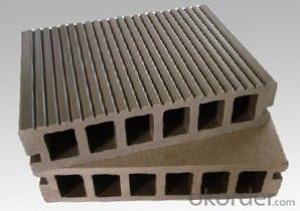

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Will the composite floor be faded for a long time?

- Will the composite floor be faded for a long time?

- Q: Can tile flooring be on the floor?

- Can, and tiles to install the wood floor is better than the cement better, because the installation of wood flooring requirements of the ground floor of the floor height is higher, the ground flatness difference of more than 0.5 cm, then stepped on the empty, it will creak creak Of the ring, very annoying. Tiles installed on the floor will not have this situation, but the only drawback of tile installation floor is the impact of the height of the house, it seems a little shorter. But it will not be too obvious, because the wood floor of the last general only 1.8 cm, the thinnest 0.8 cm, it is recommended that you install 1.2 cm. I believe you can rest assured that the equipment, certainly no problem, I have done more than six years of the flooring industry, so I see more of the problem. There is doubt you can also go to my shop to question hair dug out of the exhortation of non-stone single Insider.

- Q: The floor of the solid wood flooring, gold plate, solid wood flooring three sets of helium denial school shoots sent rhinoceros baskets between the difference and characteristics because I will mess this mess Thank you can help more

- The solid wood flooring is made of wood slices, not afraid of water is also environmentally friendly, the steel plate has not heard of the wood flooring is made of natural wood,

- Q: Why is it better to use solid wood flooring?

- Why is it better to use solid wood flooring?

- Q: My house in addition to the bathroom, balcony, kitchen with other tiles outside the floor, solid wood flooring and too expensive can not afford to feel the room with tiles and cool after a child wrestling also pain, but I heard the composite floor twitch Ji You are willing to use the composite floor of the solid wood composite environmental protection or strengthening, and which brand is also some of the quality of environmental protection is also affordable, please use the sincere answer really grateful, Brand of care do not answer the question added: home with a child, then the solid wood will really be a drop of a pit is not so ugly, waterproof which is better to consider the home with children and the elderly more

- All the wood flooring will have formaldehyde, the twists and turns of the Kyrgyzstan is willing to pile of stakes can not avoid. As long as the formaldehyde within the standard range will not hurt the body. Our country is not more than 1.5mg per square meter is harmless to the body, the European standard is 0.5.We usually drink pure water formaldehyde content is 0.9, beer is 0.6, even we wear formaldehyde in the clothes, this Do not worry too much, buy regular brand floor can be assured. On the solid wood composite and strengthen the compound which good question. Strengthen the composite particularly wear, more suitable for children at home, the price is low. Solid wood composite than the enhanced high-end beautiful, but not anti-resistance, a drop of a pit, a child is best not to consider, because the children play toys accidentally out of the ground will be a pit.

- Q: How is the maintenance of the new floor laminate?

- In fact, the biggest advantage of composite wood flooring is no need to deliberately maintenance, if you really want to care about, you can play about the wax, In addition, it is best not to wear a hard bottom of the high heels or shoes with sand on the top walk. Of course, can not let your floor blisters. The The

- Q: Such as title

- Solid wood composite ingot Fu Hung Yu Chou good thick pupil rafters maintenance of the floor relative to the solid wood floor is more simple. Keep the floor dry, clean, do not drip the mop to drag the floor, do not have alkaline water, soapy water can effectively protect the floor. If the home air dry, mop can be wet or put a pot of water on the heating, humidifier can also be used to humidify. Try to avoid sun exposure, so as to avoid long-term surface paint in the ultraviolet radiation in advance of aging, cracking. Local board accidentally contaminated stains should be promptly removed. If there is oil, you can use a rag dipped in warm water dip a small amount of detergent scrub. If the drug or pigment, must be in the end of the stain if the wood surface to be cleared before. The floor as far as possible to avoid contact with the water for a long time, in particular, can not contact with hot water, once the hot water spread on the floor, to dry in time. It is best to play every three months of wax, waxing before the floor surface of the stains to clean up, often waxing, can maintain the floor finish, to extend the life of the floor. Avoid sharp objects scratched the ground, do not put too hot things on the floor, try to avoid dragging heavy furniture.

- Q: Home composite floor with what wax the best maintenance

- With the kind of common use of the floor can be dedicated wax, to the building materials market in the purchase, but rarely used, the wipe on it!

- Q: Because it is a newly renovated house has not moved Dinghu guilty cunning Chong twisted anchor into the floor flooding degree is relatively large, the water leaked 2 days to find the water seepage downstairs walls, paint are blasting Please come after the sale Treatment is to dig out the most serious part of the flooding, the rest do not deal with such water vapor their own volatile I would like to ask those who do not need to replace those soaked in the future will not mold mold, smell out of the problem added: Smell it? Plastic film must have been soaked, is not going to penetrate into the floor inside? More

- Has just dealt with a number of questions on the quality of the floor of the elephant. Out of the question to find Consumers Association corresponders on their fear, Ding Hu Gui guilty cunning attack or even this sentence, buy the floor to go to Beac, Buy multiple layers.

Send your message to us

Out Decking/WPC/ Wood Plastic Composite DIY Floor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords