Our Best Pre-Painted Galvanized/Aluzinc Steel Coil for Roof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

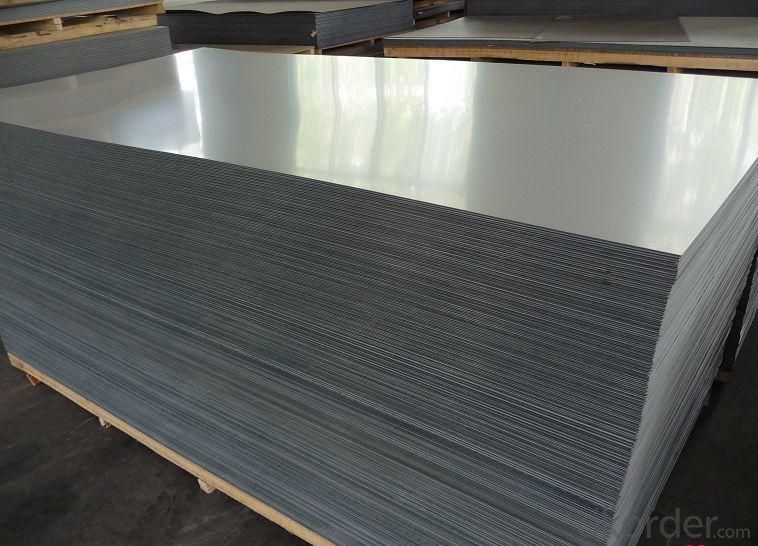

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the difference between regular steel stainless steel? Why does steel rust but stainless wont? Is stainless some kind of alloy or something? Any knowledgeable input would be great. Thanx!

- In metallurgy, stainless steel is defined as a steel alloy with a minimum of 11.5% chromium content by mass. Stainless steel does not stain, corrode or rust as easily as ordinary steel (it stains less), but it is not stain-proof. It is also called corrosion resistant steel when the alloy type and grade are not detailed, particularly in the aviation industry. There are different grades and surface finishes of stainless steel to suit the environment to which the material will be subjected in its lifetime. Common uses of stainless steel are cutlery and watch straps. Stainless steel differs from carbon steel by amount of chromium present. Carbon steel rusts when exposed to air and moisture. This iron oxide film is active and accelerates corrosion by forming more iron oxide. Stainless steels have sufficient amount of chromium present so that a passive film of chromium oxide forms which prevents further corrosion

- Q: How are steel coils used in the manufacturing of metal containers?

- Steel coils are used in the manufacturing of metal containers as they are typically unrolled and cut into specific sizes and shapes to form the body of the container. These steel coils provide strength and durability to the containers, making them suitable for storing various products such as food, beverages, chemicals, and more.

- Q: I am in the US and looking for a price on wide flange steel. I need a price of one W10x30 and 20 feet long.

- The price of steel is increasing daily, so an exact answer is rough. A W10x30 is a fairly common shape and shouldn't be too hard to find. For a very rough ballpark number, say $700/ton (installed price), the piece you require should be in the range of about $250.00 or less as I assume you'll be doing the installing. Please don't take this as the gospel, however. Price varies on location, stock, and availability. Open the phone book and contact your local steel supplier. Because the piece you require is fairly short, you might get lucky and find someone who has a waste piece that length that they will give you a good deal on. --------------------------------------... I just checked the AISC web site to verify the number I quoted above and they posted an article stating that the average mill price had just increased to over $1000/ton in May. The best advice I can provide at this point is to buy the W10 now and don't wait any longer.

- Q: What are the different types of steel finishes available for coils?

- There are several types of steel finishes available for coils, including hot rolled, cold rolled, galvanized, and stainless steel. Hot rolled steel has a rough surface and is often used for structural applications. Cold rolled steel has a smoother surface and is commonly used in appliances and automotive parts. Galvanized steel has a protective zinc coating to prevent corrosion and is used in outdoor applications. Stainless steel is resistant to corrosion and staining, making it suitable for food processing and medical equipment.

- Q: How are steel coils used in the production of scaffolding?

- Steel coils are used in the production of scaffolding as they are typically cut and shaped into various components such as tubes, frames, and brackets. These coils provide the necessary strength and durability required for scaffolding structures, ensuring the safety and stability of workers who use them.

- Q: How are steel coils used in the production of automotive exhaust systems?

- Steel coils are used in the production of automotive exhaust systems as they are shaped and formed into various components such as pipes, mufflers, and catalytic converters. These coils are cut, bent, and welded to create the necessary shapes and sizes required for efficient exhaust flow and noise reduction. Additionally, the strength and durability of steel make it an ideal material for withstanding high temperatures and harsh conditions that exhaust systems endure.

- Q: an 18k steel and gold, screw style bracelet how much would it be worth?

- Steel does not come in an 18k version and is worth only about $1.50/pound. 18k gold (.750 or 75% pure) is currently worth about $40.20/gram, based on the spot price of gold of $1,667/ounce at this moment.

- Q: How does adding carbon to Iron make it stronger? How does steel look the molecular structure in comparison to Iron? looking for a very scientific answer =]

- Cast Iron' is typically brittle, while 'Maleable Iron' has a small percentage of carbon which allows it to be hammered and formed. Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron. Steel is a crystalline structure of iron molecules interspersed with carbon molecules. This is properly known as cementite. The hardness and malleability of steel depends not only on the carbon content, but on how the carbon and iron molecules are arranged to one another. Internal stresses in the steel's crystalline structure will increase or decrease depending on the temperature it is subjected to and the rate at which molten steel is cooled. This 'tempering' can increase the strength of the steel at the expense of brittleness.

- Q: Hello. right now i have been playing electric and acoustic guitar for 6 years. I currently became very interested in learning the pedal steel guitar. I will be teaching myself so is it really hard to learn? Are there a lot of songs online that could give me tabs? Basically im asking if it is worthwhile to spend a lot of money. I dont want it if there are only 3 songs im gona learn. im up for the challenge im just curious how hard it was to learn. thanks for your help.

- 12 string guitars have harmonies. Theres the original six sounds, but the extra harmonies. 12 string guitars are slightly harder to play and not good for beginers

- Q: What are the common coil storage conditions?

- The common coil storage conditions include keeping the coils in a dry and well-ventilated area, away from direct sunlight and extreme temperatures. It is also important to store the coils in an upright position, on pallets or racks, to prevent damage and ensure easy access for handling and transportation.

Send your message to us

Our Best Pre-Painted Galvanized/Aluzinc Steel Coil for Roof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords