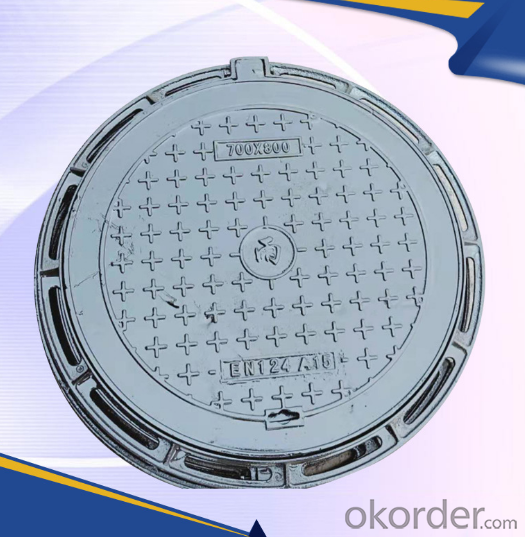

OEM ductile iron manhole covers with superior quality manufactured in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Samples are available for free.

2. Our products: produced by the hydraulic Press.

3. Our price: we are the factory that provide the most competitive price with good quality, and large order quantity will get big support by us! Meanwhile, our products are hot sale in China also the rest of the word.

4. Our srevice: OEM srevice.

(If you have any problems, please do not hesitate to contact us!)

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| TD1221 | D400 | 1220*675 | 1378*831 |

| TD1222 | D400 | 1220*675 | 1370*830 |

Advantages

Compressive prices, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast iron manhole covers but the cost is 30% or so lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. What is your minimum order requirement?

A: We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

3.How do we start our cooperation?

If you are wholesalers, please send us the detailed information of the products you are handling, like Cover size, clear opening size, loading Grade and so on. we will give you our best advices. We can start from sample order.

Sometimes if meet the size we don’t have, the new mould with your size and design can be considered from us. Let's talk more details about the New Mould and Charges.Then start our Cooperation.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting.

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- For the nodular cast iron, the hardness, strength and wear resistance are improved, such as used in the manufacture of automobile, tractor, diesel engine crankshaft, connecting rod and other important parts. A normalizing and hypereutectoid ball annealing before, can eliminate the mesh two cementite spheroidizing annealing, to ensure that all spheres of cementite. Annealing is a metal heat treatment process, which means the metal is slowly heated to a certain temperature, sufficient for a long time, and then cooled at an appropriate speed. The purpose is to reduce hardness, improve machinability, eliminate residual stress, stabilize size, reduce deformation and crack tendency, refine grain, adjust microstructure and eliminate tissue defects. Its purpose: (1) reduce hardness and improve machinability; (2) eliminate residual stress, stabilize size, reduce deformation and crack tendency; (3) refine grain, adjust microstructure and eliminate tissue defects. In production, annealing process is widely used.

- Q: The casting defects of pores, trachoma how to repair?

- Metal repair can be used to fill the repair. Airhole 2mm following LT102 recommend the use of liquid metal repairing agent.

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What is the difference between casting and stamping parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

OEM ductile iron manhole covers with superior quality manufactured in Hebei

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches