Non Woven Coir Geotextiles - Continuous Filament PET Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PET Woven Geotextile

PET Woven Geotextile Introduction

Woven Geotextile is made of high tenacity and high molecular weight polyester yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

PET Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

PET Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

PET Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

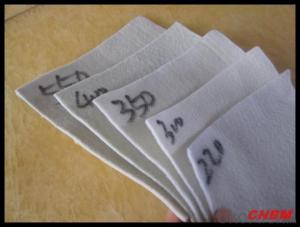

PET Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: What are the applications of geotextiles in geotechnical engineering?

- Geotextiles have a wide range of applications in geotechnical engineering. They are commonly used for soil stabilization, erosion control, and drainage systems. Geotextiles can be used to reinforce soil, preventing slope failures and improving the stability of embankments and retaining walls. They also serve as a barrier against soil erosion by maintaining the integrity of the soil structure. In addition, geotextiles are used for filtration and separation purposes, allowing water to pass through while preventing the movement of fine particles. Overall, geotextiles play a crucial role in enhancing the performance and longevity of various geotechnical structures.

- Q: What are the specifications for geotextiles in sediment control projects?

- The specifications for geotextiles in sediment control projects typically include factors such as material type, weight, tensile strength, permeability, and durability. These specifications ensure that the geotextiles effectively prevent soil erosion, retain sediment, and allow for proper drainage in sediment control projects.

- Q: Geotextile in the asphalt layer under what role

- Geotextile manufacturers need to elaborate

- Q: How do geotextiles help with sediment control in water bodies?

- Geotextiles act as a physical barrier that prevents sediment from entering water bodies. They are designed to filter and separate sediment particles, allowing water to pass through while retaining the sediment. This helps in reducing erosion, improving water quality, and protecting aquatic ecosystems from the harmful effects of sedimentation.

- Q: What are the different geotextile installation techniques for roadways?

- There are several different geotextile installation techniques for roadways, including the overlay method, the trench method, and the sandwich method. - The overlay method involves placing the geotextile directly on top of the existing soil or subgrade before adding the new road material, such as asphalt or concrete. This technique helps to separate the soil layers and prevent the mixing of materials, providing stability and reducing the risk of road failure. - The trench method involves excavating a trench along the road alignment and placing the geotextile in the trench before backfilling it with soil or aggregate. This technique is commonly used for drainage applications, as the geotextile acts as a filter to prevent fine particles from clogging the drainage system, while allowing water to flow through. - The sandwich method is a combination of the overlay and trench methods. It involves placing a layer of geotextile between the existing soil and the new road material, as well as placing another layer of geotextile on top of the new road material. This technique provides additional reinforcement and separation, enhancing the overall performance and durability of the roadway. Overall, the choice of geotextile installation technique depends on the specific requirements and conditions of the road project, such as soil type, traffic load, and drainage needs.

- Q: Can geotextiles be used in geosynthetic clay liners?

- Yes, geotextiles can be used in geosynthetic clay liners. Geotextiles are often used as a protective layer or separator between the clay liner and other materials in order to enhance the performance and longevity of the geosynthetic clay liner system.

- Q: This is a large sample of gravel anti-filter how this project count

- Lack of slope and total length, can not accurately calculate the amount of engineering. Approximate estimates of cross-sectional area, then only a few simple graphics: clay tamping (rectangular), coarse gravel (trapezium), gravel and gravel (zoned plus parallel quadrilateral), geotextile (four sections)!

- Q: What are the different geotextile reinforcement techniques?

- Some of the different geotextile reinforcement techniques include mechanical stabilization, soil confinement, and erosion control. Mechanical stabilization involves using geotextiles to increase the strength and load-bearing capacity of soils, such as in road construction or retaining walls. Soil confinement refers to the use of geotextiles to prevent soil erosion and maintain the stability of slopes or embankments. Erosion control techniques involve using geotextiles to protect soil surfaces from the erosive forces of water or wind, helping to maintain the integrity of the landscape.

- Q: What are the advantages of using geotextiles in green roof systems?

- There are several advantages of using geotextiles in green roof systems. Firstly, geotextiles act as a barrier between the growing medium and the drainage layer, preventing soil erosion and ensuring proper water drainage. This helps to maintain the integrity and stability of the rooftop garden. Secondly, geotextiles can enhance water retention and reduce irrigation needs by improving moisture distribution throughout the green roof system. This promotes healthier plant growth and reduces the overall maintenance requirements. Additionally, geotextiles provide an added layer of protection against root penetration, preventing potential damage to the roof membrane. Overall, the use of geotextiles in green roof systems helps to optimize the performance, longevity, and sustainability of these systems.

- Q: Can geotextiles be used in coastal erosion control structures?

- Yes, geotextiles can be used in coastal erosion control structures. Geotextiles are permeable fabrics that can be placed directly on the soil surface or embedded within it to enhance erosion control. They can help stabilize coastal slopes, prevent soil movement, and provide protection against wave action and erosion.

Send your message to us

Non Woven Coir Geotextiles - Continuous Filament PET Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords