JS Elastomeric Compound Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Compound Waterproof Coating Description:

Compound waterproof coating is a new green waterproof coating recommended by the ministry of construction of China. composite of two-component waterproof coating,organic liquid and inorganic powder. It has the advantage of high elasticity of organic material and advantages of good durability of inorganic materials . After coated ,it can cover can form high elastic high-strength waterproof coating, and can be according to need to make color coating.All kinds of old and new buildings (example: the roof of the building, underground, external wall, toilet bath and tunnels, Bridges, pool, etc.) for waterproof engineering all can be used.

2.Main Features of Compound Waterproof Coating:

•High strength, water resistance, weather resistance, excellent durability

•Can be added pigment, in order to form colour coating

•Non-toxic, tasteless, no pollution in cold constructionsafe and simple, short time for construction

•High temperature up to 140 ℃

3.Compound Waterproof Coating Specification:

| Name | Test Item | Index | ||

| Compound Waterproof Coating | Solid content | ≥92% | ||

Tensile strength Mpa | ≥1.9 | |||

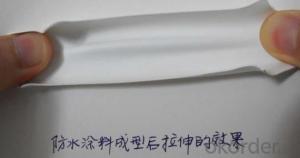

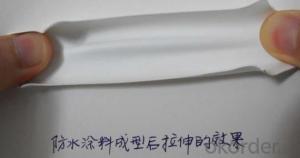

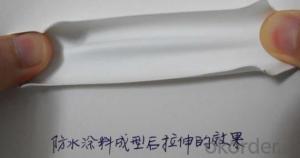

| Elongation at break | ≥550% | |||

| Flexibity at low temperature | ≤-40 |

4.Compound Waterproof Coating Image:

- Q: What is PE waterproof cloth and PVC tarpaulin

- PVC (tarpaulin) Features: coated high-strength polyester waterproof cloth is a high-strength polyester canvas-based cloth, coated with polyvinyl chloride (PVC) paste resin with accelerator, anti-mildew agent, anti-aging agent, anti Electrostatic agents and other chemical additives, made by high temperature plastic. Waterproof, anti-aging, anti-static and other properties; and the product breaking strength, tear elongation, tear strength is much better than the traditional tarpaulin; product appearance colorful, it is pleasing to the eye. The surface of the special treatment from the anti-skid effect, is the international popular waterproof cloth, and the width of large, reaching 2 meters wide, processing products can reduce the patchwork to improve the quality, can be used to heat sealing stitching, The And according to user needs to produce different functions, different colors, different thickness of the product.

- Q: Find the construction steps for waterproof coatings

- 3, note (1) rain weather and five wind above the weather shall not be construction. (2) coating waterproof layer shall not have bottom leakage, cracking, holes and other defects and peeling, bubbling, carcassing and wrinkle phenomenon. Coating waterproof layer and the base should be bonded between the solid, no hollowing, trachoma, delamination and so on. (3) the coating site should be continuous, solid, shall not appear Alice, hollowing parts. (4) rigid protective layer before the completion of any personnel shall not enter the construction site, so as not to damage the waterproof layer; coating of the overlapping parts should be care by the staff. (5) roof should be used lime soil, clay or sub-clay for backfill, thickness 50 cm, backfill shall not contain stones, gravel, ash and organic matter. Artificial compaction of each layer 25 cm, mechanical compaction of each layer 30 cm, rammed to prevent damage to the waterproof layer. In the backfill thickness of more than 50 cm, it is allowed to use mechanical backfill rolling.

- Q: What material is used for waterproofing of tarpaulin

- Cement-based waterproof paste (such as the Swiss Sika) Product category Cement-based materials non-toxic, environmentally friendly, both in the construction process also Is formed after the harmless to humans and animals.

- Q: Home improvement waterproofing problem

- 2, the ground waterproof layer generally turned 20 cm. Use the shower parts generally do more than 2.2 meters.

- Q: How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet to do waterproof, it is recommended to use kitchen and toilet waterproof paste, it is specifically for the kitchen and toilet water and easy to seepage yin and yang angle, pipe, sanitary ware, floor drain and other parts of the development, special materials, so waterproof Ordinary waterproof material is better, and waterproof coating construction is more convenient, only need to brush 2-3 times, the thickness of 1.2-1.5MM on it. Specific construction methods are as follows: 1, will penetrate the root, floor drain and other cracks, need to repair the site cut into "V" shape, and clean, sprinkler moist; 2, the [infiltration of crystalline repair mortar] add water (water and ash weight ratio of 1: 2 ~ 3) mixed evenly, in the early condensate before (5 minutes) to repair the construction, the root of the pipe, the floor drain, yin and yang, Should be made r angle; 3, repair mortar after the final setting, the [durable waterproof paste] powder and liquid material mixing evenly, put it aside for 3 minutes, and then stir evenly after brushing on the base surface, should be cross brush twice, and so on The first time after the dry, can be carried out the second time construction; 4, after the completion of anti-stamped, 48 hours after the closed water test.

- Q: What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: There is no formaldehyde in the finished putty

- Often people are talking aldehyde color change, because the formaldehyde is very polluted environment contains a lot of carcinogenic substances, so into the wall inside unknowingly become an environmental killer.

- Q: FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

- Q: What are the key points and contents of the quality control of waterproof material?

- 3, infiltration of crystalline cement-based waterproof coating: on-site fraud is to use ordinary cement mixed with seafood powder (or 801 glue) so that the cement after the solidification of the color, it will not crack. Genuine infiltration of crystalline cement-based waterproof coating will have a hydrophobic effect that is the effect of lotus leaf water droplets (of course, this hydrophobic effect can not be too much, otherwise it will affect the next process of bonding).

Send your message to us

JS Elastomeric Compound Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords