Cement-based Osmotic Crystallization Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cement-based Osmotic Crystallization Waterproofing Coating Description:

Cement-based permeable crystallization waterproofing material is a kind of inorganic gray pulverous, high efficient to protect environment waterproofing material. it has a special active substances, and it has an affinity to the water.It is a kind of catalyst.It uses the intrinsic to the chemical characteristics of cement concrete and porous, with water as the carrier and the help of osmosis, transmitting y filling in the pores of concrete,to catalyze the particacles in the concrete and the ingredients of no completely hydrating happening the hydration again. And it forms of insoluble tendrils crystal and combinewith concrete into one whole. So water and other liquids from any direction is blocked, to achieve permanet effect of waterproofing, moistureproofng and protecting steel bar and reinforcing concrete structure strength.

2.Main Features of Cement-based Osmotic Crystallization Waterproofing Coating:

•High strength, water resistance, weather resistance, excellent durability

•Can be added pigment, in order to form colour coating

•Non-toxic, tasteless, no pollution in cold constructionsafe and simple, short time for construction

•High temperature up to 140 ℃

3.Specification of Cement-based Osmotic Crystallization Waterproofing Coating

| Flexural strength | ≥2.80(7d) | |||

| compressive strength Mpa | ≥12.0(7d | |||

| Wet base adhesive strength Mpa | ≥1.0 | |||

| Permeability pressure(28d) | ≥0.8 | |||

| Osmotic pressure ratio(28d) | ≥20 |

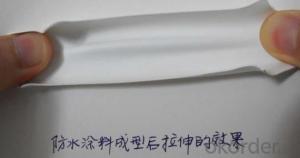

4.Cement-based Osmotic Crystallization Waterproofing Coating Images:

- Q: Bathroom first leveling or do waterproof, what is the difference

- Is the first water and then leveling. Home improvement toilet ground specific process practice: 1. The base layer, and which layer with the structural board, with cement mortar wipe. It is recommended to set the floor drain, the grassroots level should be flat and the direction of the leak to the slope. Against the wall and the root of the root should be wiped rounded.

- Q: What is the car waterproof sticker material?

- B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q: What is PE waterproof cloth and PVC tarpaulin

- PE tarpaulin, anti-aging, anti-aging, anti-corrosion, light, easy to fold, relative to the PVC tarpaulin, PE tarpaulin cheaper price for the freight yard, the service life will be shorter.

- Q: Home improvement waterproofing problem

- 3, waterproof as to do more than 2 centimeters of closed water 24 hours or more closed water test, check whether there is leaking and dampness downstairs phenomenon.

- Q: What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q: Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q: How does the finished ventilator manufacturer waterproof?

- Rooftop natural ventilator waterproofing measures are mainly two kinds, one is the traditional silicone, adhesive tape waterproof, the other is the structure of water, the national standard Atlas 11CJ33 "ventilation and light skylight" recommended the use of structural waterproof technology.

- Q: Nanning building waterproof material market where

- to buy what materials are going to go to some factories, such as paper, printing materials and other manufacturers in the Nanning High-tech Zone or Nanning Economic Development Zone may be more

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material is divided into four categories, namely, PVC material, aluminum gusset material, waterproof gypsum board, sauna board. Kitchen bathroom ceiling material 1: PVC material ????PVC is made of vinyl chloride in the role of the initiator made of thermoplastic resin, made of honeycomb shape. Suitable for use in damp places such as kitchen and toilet, because the PVC material ceiling in the life of a certain guarantee, you can use for 50 years without damage, while waterproof, heat insulation effect is good, but also has a certain noise Effect, in the kitchen is the best use of the ceiling material.

- Q: Waterproof material water leakage construction should pay attention to what

- 2, wall treatment · Wall treatment to do about 300mm high waterproof coating, to prevent water infiltration wall back tide. · Bathroom between the wall and the ground (plane and elevation) brushing height should be greater than 100mm. · The height of the shower room in the bathroom is not less than 1800mm. · If there is a bathtub, the height of the wall adjacent to the bathtub should be 300mm higher than that of the bathtub. · Waterproof height of tub is not less than 800mm. · The height of the squat should be more than 900mm. For the transformation of the toilet wall and self-built light wall, the proposed height of the waterproof to do the top.

Send your message to us

Cement-based Osmotic Crystallization Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords