HPA Geocells Fiberglass Geogrid for Asphalt Pavement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Manufacturer with Asphalt Pavement

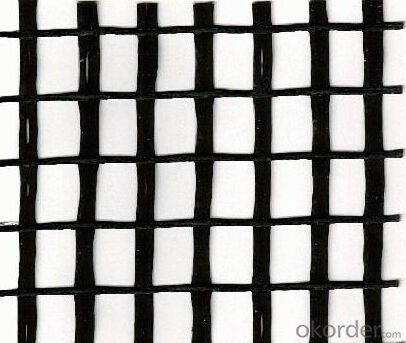

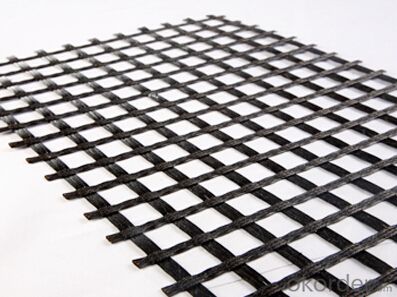

Description Of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance.The products after surface covering own the favorable property of alkali resistance and aging resistance. It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle. This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed.

Main Features of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

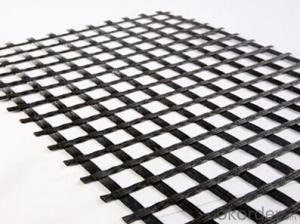

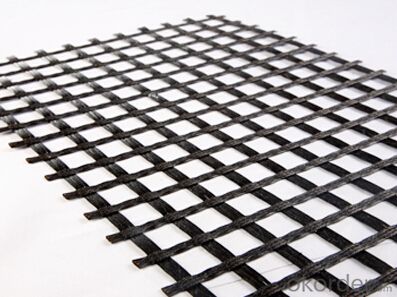

IMages of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

FAQ of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the factors that influence the design and selection of geogrids for reinforcement?

- There are several factors that influence the design and selection of geogrids for reinforcement. These include the type and characteristics of the soil, the specific application or project requirements, the anticipated loads or stresses on the geogrid, the desired design life and durability, and cost considerations. Additionally, factors such as installation conditions, site constraints, and environmental conditions may also play a role in determining the appropriate geogrid design and selection.

- Q: way grille HS codingAlso do not know what is the basis of the grid HS code pointsAlas! !Thanks in advance!!!Hard, can you tell me how much is the tax rebate rate? Thank you

- 35069190 glass fiber geogrid emulsion adhesive38249090 honeycomb packing

- Q: What is the price of geogrid? There are geogrid manufacturers that good?

- According to the general price of geogrid kn accounting, namely 10kn/m, 20kn/m, 50kn/m and so on, the higher the price the greater force kn. The raw materials of different prices in different tension kn,

- Q: Glass fiber grille material.

- Glass fiber grille is made of glass fiber

- Q: Are geogrids resistant to temperature variations?

- Yes, geogrids are generally resistant to temperature variations. They are specifically designed to withstand a wide range of temperatures, from extreme cold to high heat, without losing their structural integrity or performance. This makes geogrids a reliable and durable solution for various engineering applications where temperature fluctuations are expected.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth retaining walls on soft soils?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth retaining walls on soft soils. Geogrids are commonly used to enhance the stability and load-bearing capacity of retaining walls by providing tensile strength and reducing lateral movement of the soil. In soft soils, geogrids can help distribute the applied loads evenly and prevent excessive settlement or deformation of the retaining wall system.

- Q: What is the meaning of the geogrid check bond frequency 2%

- Geogrid has a break elongation

- Q: What is the name of the geotextile woven from polyester and polyester threads?Should be with a flat woven out, like polyester yarn is double stranded and

- Generally speaking two nouns can be used in generalThe earliest polyester is said polyester, the full name is "terephthalic acid two polyethylene glycol ester". Later, the type of polyester fiber gradually expanded, many also known as modified polyester

- Q: Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are often used as reinforcement materials in soil stabilization and retaining walls, providing strength and stability to the construction site. They can be easily installed and removed, making them suitable for temporary applications.

- Q: Can geogrids be used for reinforcement in asphalt overlays?

- Yes, geogrids can be used for reinforcement in asphalt overlays. Geogrids are commonly used in pavement applications to enhance the structural integrity of asphalt overlays by reducing cracking and improving overall pavement performance.

Send your message to us

HPA Geocells Fiberglass Geogrid for Asphalt Pavement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords