Neoly Geocells Fiberglass Geogrid High Intensity Low Elongation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Products Profile

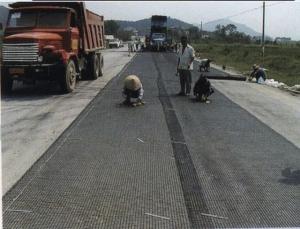

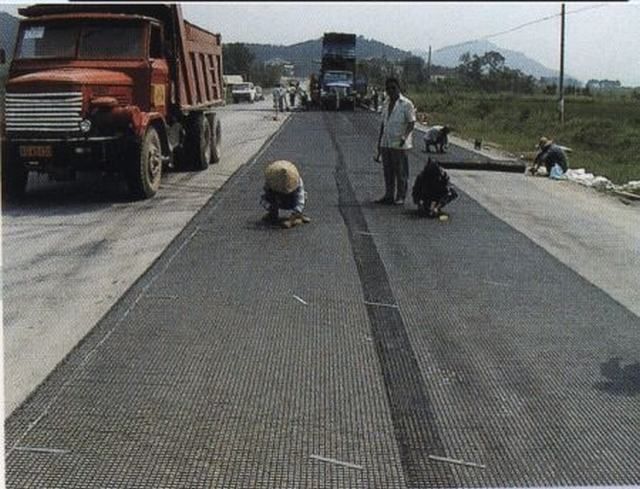

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

Fiberglass Geogrid Products Features

It is characterized by high tensile strength in axial and lateral directions low stretch rate, alkaili-resistance, low temperature-assistance as well as convenience in construcion and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Fiberglass Geogrid Products Advantages

High strength

High modulus

Low temperature resistance

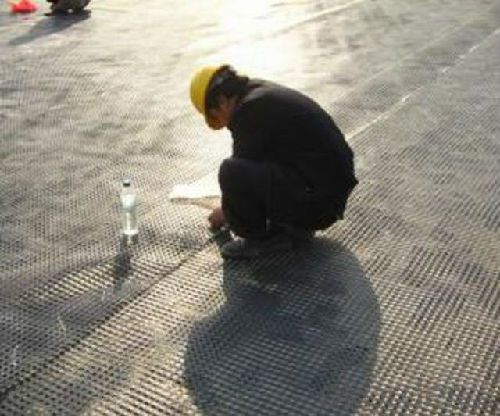

Very convenience in construction

Very competitve price

Fiberglass Geogrid Product Application:

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3. it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4. it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5. it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

Fiberglass Geogrid Technical Standard (standard type):

Geotechnological grid of fiberglass | |||||||

Performance\specification | EGA25-25 | EGA30-30 | EGA40-40 | EGA50-50 | EGA80-80 | EGA200-200 | |

Intensity | Longitudinal | 25 | 30 | 40 | 50 | 80 | 200 |

Crosswise | 25 | 30 | 40 | 50 | 80 | 200 | |

Break elongation ratio% | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

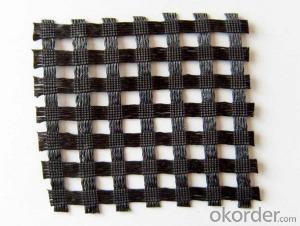

Grid(mm) | 12.7*12.7 25.4*25.4 | ||||||

Breadth(m) | 1—6 | 1—6 | 1—6 | 1—6 | 1—6 | 1—6 | |

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: How do geogrids improve the load-bearing capacity of foundations?

- Geogrids improve the load-bearing capacity of foundations by distributing and transferring the load more evenly across the soil, reducing the potential for settlement and instability. The geogrids act as reinforcement, increasing the tensile strength of the soil and preventing excessive lateral movement. This results in a more stable foundation that can support heavier loads and withstand external forces such as wind or seismic activity.

- Q: What are the benefits of using geogrids in construction?

- Geogrids offer numerous benefits in construction, including improved soil stability, enhanced load-bearing capacity, and increased durability of structures. They help to distribute and reinforce loads, reducing the risk of soil settlement and potential damage to the infrastructure. Geogrids also prevent soil erosion, provide effective drainage, and are cost-effective compared to traditional construction methods. Overall, their use in construction improves the longevity and performance of the built environment.

- Q: Geotextiles for geotextiles - Specification for geotextiles

- 5Protective effect of 6. It has the following characteristics as non-woven geotextile has more than six functions, so it can be widely used in railway, highway, sports venues, dams, water conservancy construction, tunnel, coastal beach reclamation, environmental engineering,. The application of the field of water conservancy engineering geotextile: Seawall dyke Lake embankment projecttarget reservoir; reinforcement; reclamation project; flood control. Highway and railway port engineering: soft foundation reinforcement treatment; slope protection; pavement anti reflection crack structure layer; drainage system; green isolation belt. Electrical engineering: nuclear power plant foundation engineering; thermal power ash dam project; hydropower station project. Port and Waterway Engineering: the performance and application of the port geomembrane: the product has excellent filtration, drainage, isolation, reinforcement, protection. Can be widely used in railway, highway, water conservancy construction, sports hall, dam, tunnel, coastal beach, Ken, environmental protection, power plant, around the airport project.

- Q: How do geogrids enhance the stability of embankments?

- Geogrids enhance the stability of embankments by providing reinforcement and increasing the load-bearing capacity of the soil. They act as a structural element by distributing the applied loads more evenly, reducing the risk of slope failure and settlement. Additionally, geogrids increase the shear strength of the soil, preventing lateral movement and erosion, thereby improving the overall stability of the embankment.

- Q: Are geogrids resistant to hydrolysis?

- Yes, geogrids are generally resistant to hydrolysis.

- Q: Can geogrids be used in reinforcement of embankments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of embankments on collapsible soils. Geogrids provide additional stability and strength to the embankment, helping to prevent soil collapse and reduce potential settlement. By distributing loads more evenly, geogrids can effectively reinforce the embankment and improve its overall performance on collapsible soils.

- Q: Self adhesive fiberglass geogrid price 1m2 how much money

- The higher the tension, the higher the price

- Q: What are the benefits of using geogrids in construction projects?

- Geogrids offer several benefits in construction projects, including increased soil stability, improved load distribution, and enhanced overall structural integrity. These materials reinforce and stabilize the soil, preventing erosion and reducing the risk of slope failure. Geogrids also help distribute loads more evenly, reducing stress on the construction materials and extending their lifespan. Additionally, geogrids can be cost-effective as they often require less excavation and backfill material, saving time and resources during construction.

- Q: Are there any environmental concerns associated with geogrids?

- Yes, there are a few environmental concerns associated with geogrids. The production of geogrids involves the use of non-renewable resources and energy, which contributes to carbon emissions and environmental degradation. Additionally, the disposal of geogrids after their useful life can pose challenges as they are often not biodegradable and may end up in landfills. However, when used properly and managed responsibly, geogrids can still provide environmental benefits such as erosion control and soil stabilization.

- Q: In the reinforced earth retaining wall, the geogrid is connected with the panel

- In order to ensure the continuity of the reinforced soil, laying in the void design based on the engineering environment need to be flexible, prefabricated into various shapes, can provide the same type of geogrid small pieces of good, and cover all the reinforced area; for bend shop visual effect; can also use color cement, add art wall. No panel reinforcement design of geogrid, in the corner there will be some overlap in geogrid, geogrid reinforced earth retaining wall is also called anti package type or wrap-reinforcedearth retaining wall, the wall is made of mesh bags to fill the overlap coefficient of friction will be reduced, must be laying a layer of 10mm ~ 20mm thick the soil geogrid anti package into each layer of geogrid is a special connecting rod is connected with the shape of the coarse sand layer, separate the two layer of Geogrid to ensure friction resistance. As a whole, the mesh bag filling has been mixed for local growth of grass and shrub seeds, seeds, after months of growth after the formation of green ecological wall. The utility model not only protects the safety of the geogrid, but also beautifies the environment of the retaining wall project.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Neoly Geocells Fiberglass Geogrid High Intensity Low Elongation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords