Neoly Geocells for Civil Engineering with Low Elongation Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

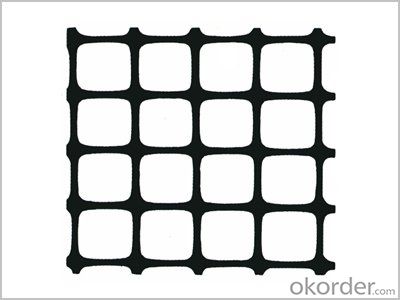

Type:

Geogrids

Place of Origin:

Jiangsu, China (Mainland)

Brand Name:

Lonrace

Model Number:

geogrid

Material:

Polyester

Geogrid allows assembling within the temperature range from -40°C to +60°C. The material is neutral to aggressive environments and ecologically safe. Laying does not require additional machinery. In fold position geogrid does not take much place.Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Slopes and subgrades with rails are a serious problem in railroad construction. Under high pressure the layers slide and deform consequently causing rail deformation, which requires closing railroad segments for a long time. Geogrid application allows carrying out comlex repair operations of the necessary road segment in shortest time (which is very essential in transportation).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geogrids suitable for reinforcing landfill caps?

- Yes, geogrids are suitable for reinforcing landfill caps. Geogrids are commonly used in landfill engineering to enhance the stability and strength of landfill caps. They provide reinforcement and prevent the movement and erosion of soil, thereby increasing the overall efficiency and effectiveness of landfill caps in containing waste materials.

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are commonly manufactured using materials such as polyester, polypropylene, fiberglass, and steel.

- Q: Can geogrids be used in gabion wall construction?

- Yes, geogrids can be used in gabion wall construction. Geogrids are commonly used as reinforcement materials in gabion walls to enhance their stability and strength. They help distribute the load from the wall evenly, preventing bulging or deformation. Additionally, geogrids can also improve the overall performance of gabion walls by reducing settlement and increasing the resistance to external forces such as earthquakes or water pressure.

- Q: Can geogrids be used in slope protection systems?

- Yes, geogrids can be used in slope protection systems. Geogrids are commonly used to reinforce slopes by providing stability and preventing soil erosion. They can be installed horizontally or vertically to improve the strength of the soil and enhance the overall performance of slope protection systems.

- Q: Can geogrids be used in reinforcement of underground storage facilities for hazardous materials?

- Yes, geogrids can be used in the reinforcement of underground storage facilities for hazardous materials. Geogrids are highly effective in providing soil reinforcement and stabilization, which is crucial for ensuring the structural integrity and safety of underground storage facilities. By enhancing the load-bearing capacity of the surrounding soil, geogrids can help prevent ground movements and potential leaks or ruptures, thereby minimizing the risks associated with storing hazardous materials.

- Q: Are geogrids resistant to temperature variations?

- Yes, geogrids are generally resistant to temperature variations. They are specifically designed to withstand a wide range of temperatures, from extreme cold to high heat, without losing their structural integrity or performance. This makes geogrids a reliable and durable solution for various engineering applications where temperature fluctuations are expected.

- Q: Refers to the size of the geogrid mesh holeSpecific attention is not clear, the banner of Chang Chang official CafeThere's something you're looking forGrille generally by the vertical and horizontal staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Geogrid generally by horizontal and vertical staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Q: How do geogrids improve the performance of reinforced soil retaining walls?

- Geogrids improve the performance of reinforced soil retaining walls by adding tensile strength and enhancing stability. They are typically made from high-strength materials such as polyester or polypropylene, which provide reinforcement to the soil mass. When geogrids are incorporated into the retaining wall design, they effectively distribute the applied loads, reducing the stress on the soil and preventing wall failure. Additionally, geogrids increase the overall stiffness of the reinforced soil, minimizing deformation and settlement. This reinforcement technique enables the construction of taller and more structurally sound retaining walls, ensuring long-term stability and improved performance.

- Q: What are the factors affecting the durability of geogrids?

- The factors affecting the durability of geogrids include the quality of materials used in manufacturing, the level of UV resistance, the ability to withstand chemical exposure, the design and construction of the geogrid, and the conditions and environment in which it is installed.

- Q: Can geogrids be used in mechanically stabilized earth walls?

- Yes, geogrids can be used in mechanically stabilized earth walls. Geogrids are commonly used as reinforcements in mechanically stabilized earth walls to improve their stability and strength. They effectively distribute the forces within the soil and reduce potential wall failure.

Send your message to us

Neoly Geocells for Civil Engineering with Low Elongation Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords