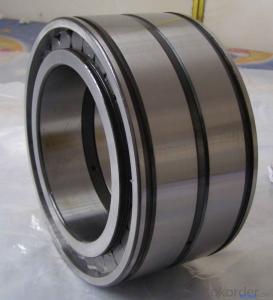

Needle Roller Bearing K 12X17X13 High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Product | Best Price Needle Roller Bearing K 12x17x13 |

Precision Rating | ABEC1,ABEC3,ABEC5 |

Clearance | C0,C2,C3,C4,C5 is available |

Sealed Cap | Rubber or Metal |

Paypal | Acceptable |

OEM | Accept |

Vibration Level code | V1,V2.V3 |

Material | Gcr15 |

Seals Type | ZZ/ZRS.RZ/RS. Open |

Mass | 0,0044kg |

Bore Size | 12 mm |

Outside Diameter | 17 mm |

Hign | 13 mm |

Regular export packing | Plastic drum+White box+ carton |

industrial packaging or as your requirement | |

MOQ | 1 pcs |

Delivery Time | 3-7 days after receiving your payment |

Payment Terms | L/C,T/T,Western Union |

Port of shippment by sea | Shanghai,guangzhou,qingdao |

Place of Origin | China |

Samples | Available |

Product Advantage:

1.High Precision Needle Roller Bearing

2.ISO Standard Bearing

3.High quality &competitive price

4.Many famous brand is available

5.Low Noise & Long life

Our advantages:

1. Manufacturer,the most competive price and good quality

2. Perfect group of technical engineers give you the best support

3.Well-trained group of international sales provide the best service

4.OEM brand aviliable

5.Rich stock and quick delivery

Shipping:

1.Small quantity, can delivery by global express: DHL TNT FedEx ARAMEX EMS UPS.this is door to door.

2.Large quantity, can delivery by air, by sea, this is port to port.

Payment:

T/T, L/C, Money Gram, Payal, Western Union etc.

Lead Time:

Sample Lead-times: generally 3-5 workdays.

Production Lead-times: 3-5 days after get payment or as contract required

- Q: I got a new bmx frame, my old one was flatland and looked funny on all my street parts.Anyway, i tried putting my old fork into the new frame, along with everything else to see if it would even fit. When i put in the fork, obviously it fit since its standard 1-1/8. However,once i tried pushing the fork all the way up, the bearings at the bottom wouldn't allow the fork to go any higher, they seem to big for the frame. i took the bearings out and tried the fork alone, the fork fits fine and looks like there is still space for bearings, but much smaller bearings. is there such a thing? smaller bearings? i thought it was all standard.. if there are i will simply go to the bike shop and buy these bearings.

- In the old days they just put grease, and roller bearings until it was full, then reassemble.Depends on the races.

- Q: i wannn know to see if its a good idea to try :)

- The gasoline will strip away the grease that lubes the bearings. It will make the bearings wear out faster if thats what you are wanting.

- Q: I'm getting some ABEC 5 bearings, but I don't know if I need them sealed or shielded. Right now I'm a beginner so I'm just cruising with the occasional hill if that makes a difference in what I need.

- Some people mistakenly call shields as seals. No one actually uses seals on skates or boards, they create too much drag. If the drag wasn't there, they would be great since they would actually keep water out. It doesn't matter if you get bearings with metal shields or the neoprene coated ones (more likely to be mistakenly called seals. The neoprene ones are all removable for cleaning and lubricating. Most metal shields are removable but occasionally you find non serviceable bearings that have shields that are permanently staked in place. With some work, you can remove the shields on non serviceable bearings by destroying one of them. You only need one shield that is the side of the bearing you see from the outside.

- Q: Im just wondering how important it is to clean and regrease a cars wheel bearing. Working as a bicycle mechanic, this is something I do on a daily basis to every other bike we work on. And so Ive always wondered why I dont hear about wheel bearing going out on cars, or why I dont hear about having them serviced...Im assuming they are sealed bearings, but still it seems like they should need serviced every so often. I drive an early 90s ford truck, nothing fancy. Is this something I should consider doing, or should I not worry about it unless they start making noise?Thanks!

- you rarely hear them going out on cars because most of the time the symptom gets disguised by worn brakes, when its the wheel bearing your brakes will get worn quicker, if you have a hub rotor designed for brakes then every time someone takes out the rotor they should have cleaned and repacked that rotor. if you have a floating rotor the bearings are pressed in and not really practical for servicing

- Q: I have a 2001 Dodge Durango and it has been making a roaring/humming noise when I drive usually it gets loud when I get up to 15-20 mph. The rpm's are fine and it doesn't overheat so I suspected my wheel bearings. This morning, I jacked up the front and tested both tires. The passenger side had a lot of play in it and when I spun the wheel, it made a slight grinding noise as if something was rubbing. The driver side did not make this noise.1) is this a problem with the bearings?2) if yes, what goes into replacing them?3) is there a website that gives step-by-step instructions for replacing them?

- 2 wheel drive or 4 wheel drive??

- Q: How do i put bearings in a skateboard if i dont have a tool?

- Best way is just push them in with your fingers or place one in the wheel and slide in on the truck and turn it over and do the other side that works good, they pop in place with a little presure from your hand onto the truck. Good luck

- Q: I have a shaft that is in a vertical position. I need to support the axial (vertical) and the radial (side) force. I can understand how to support the side force with the ball bearings. I would just slip the bearings through the shaft and then create some kind of housing and bolt it to a structure close to it. But the radial force? The ball bearings I have do not have any type of set screw, so their is nothing to lock it into place.

- You might want to think about using a conical bearing race. It can support both rotational and thrust forces. Without knowing the specifics of the application,It's not possible to recommend a specific one. Ask again with specifics- shaft dia. rpm's- torque, etc. and I'll try to help you ! Good Luck !!

- Q: how long do skatebaord bearings last?

- Depends on what kinda they are. I've seen cheap $10 Abec 3s and 5s works just as fine as some Bones bearings. As long as you take care of them, they will stay in good condition. But since a decent set of bearings don't cost all that much, just use them until you feel like changing them. I've skated for 5 years and I had a set of bearings that lasted me through out the year. Bones REDS? I'm pretty sure you're familiar with the name. But they are really durable. They ain't fast, but they are durable.

- Q: I have a pair of rx15 bauer roller blades and I need to get new wheels, bearings and spacers for them. I am a hockey player so I need some good wheels and bearings that will hold up, but I also don't want them to be expensive. If anyone has some good suggestions that would be great. I usually just buy the stock bearings and wheels, but they are getting expensive. Also is it worth it to get bigger wheels for the back two and smaller ones for the front?

- you can get any number of any parts that you want.

- Q: So my wheels used to spinn for 1 minute and a half...now if only spinns for 20-30 sec due to the rust...is it worth switching to bones reds? Will it make them spin for more than 20-30 sec?Thank You

- Yes it will make them go faster and longer provided you don't let them rust again and grease the once in a wile. Bone Red Swiss are good but generally all Bone Reds are good.

Send your message to us

Needle Roller Bearing K 12X17X13 High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords