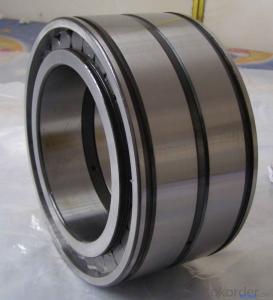

The supply of high-quality entity ferrule needle bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Entity by a needle bearing ring or two rings and a cage with needle rollers. According to different applications, can be divided into the bearings with inner ring or inner ring.Therefore, the physical ring needle roller bearings can meet the requirements of light weight, small space occupation, large transmission power requirements. Size and higher carrying capacity physical ring needle roller bearings with smaller.

The main structures

Outer double wall (or double lock ring) with cage of needle roller bearings NA, NKI type

The inner and outer rings can be installed separately (with a lock ring, a full set of needle roller and cage), access high speed, divided into single and double row two.

If the shaft can not be used as a raceway, hardened shaft that if grinding is not possible orthe economy, you can use these needle roller bearings with inner ring.

There is no inner needle bearing cage

NA, NKI type bearings without inner ring is RNA, NK type needle roller bearings.

Such bearings without inner ring, radial mounting dimensions for the supporting structurerestricted, and the match of the journal bearing is directly used as a rolling surface. As a raceway shaft, and grinding the hardware must be quenched, and only be processed to the appropriate size and shape accuracy, service life and operation precision set of needle roller bearings to higher. At the same time, because of the inner ring, the diameter of the shaft may also be appropriate to increase, thus increasing the rigidity.

Sealed needle roller bearings with or without inner ring

Needle roller bearings, single or double seal can effectively prevent the intrusion of dirt,bearing in lithium base grease amount. This type of bearing inner ring outer ring width than, and ensure a good seal and prevent injury to the bearing pollution can also which makes the bearing have micro displacement in the shaft to the bearing box. The inner ring of the bearing has the lubrication oil hole, can be configured according to the needs, from the outer ring or inner added lubricating.

Entity by a needle bearing ring or two rings and a cage with needle rollers. Size and higher carrying capacity it has smaller. Therefore, the bearing can meet the light weight, small space occupation, large transmission power requirements. According to different applications, can use the bearings with inner ring or inner ring. Outer double wall (or double lock ring) with cage of needle roller bearings NA, NKI type

The inner and outer rings can be installed separately (with a lock ring, a full set of needle roller and cage), access high speed, divided into single and double row two.

If the shaft can not be used as a raceway, hardened shaft that if grinding is not possible orthe economy, you can use these needle roller bearings with inner ring.

2 there is no inner needle bearing cage

Edit

NA, NKI type bearings without inner ring is RNA, NK type needle roller bearings.

Such bearings without inner ring, radial mounting dimensions for the supporting structurerestricted, and the match of the journal bearing is directly used as a rolling surface. As a raceway shaft, and grinding the hardware must be quenched, and only be processed to the appropriate size and shape accuracy, service life and operation precision set of needle roller bearings to higher. At the same time, because of the inner ring, the diameter of the shaft may also be appropriate to increase, thus increasing the rigidity.

3 with or without inner ring sealed needle roller bearing

Edit

Needle roller bearings, single or double seal can effectively prevent the intrusion of dirt,bearing in lithium base grease amount. This type of bearing inner ring outer ring width than, and ensure a good seal and prevent injury to the bearing pollution can also which makes the bearing have micro displacement in the shaft to the bearing box. The inner ring of the bearing has the lubrication oil hole, can be configured according to the needs, from the outer ring or inner added lubricating.

- Q: I'm asking this because like every time I googled it, it came up with answers from like 2-3 years ago.. So basically I'm just wondering if it is still not good for them... Also I would like to know what cleaners i should use for mine, and types of lubricant.. Thanks so much.

- WD-40 is not a lubricant. It's a penetrant, usually for use for rusty bolds or hinges. You can use paint thinner to clean bearings and use light weight oil to lubricate them once they dry. Don't use too much oil or it will slow the bearing down and also attract dirt. Just a thin layer of coating on the ball bearings. If you want the service life longer you could also use grease to lubricate them, but it will slow it down, but offer more protection. It's up to you to choose between protection and speed.

- Q: The bearings on one of my longboard wheels got rusted. I feel like it's unnecessary to buy a whole new set of bearings when only two of them are messed up, but it's pretty noticeable. Any hope for fixing them?And don't suggest WD-40. It screws up your bearings.

- I heard that soaking them in Coca Cola will get rid of the rust (but you gotta clean them realllly good after). Otherwise, you can buy another set of bearings, then when some of them rest, mix and match and throw out old, rusted bearings as needed.

- Q: how long does crankshaft bearings take to replace on snowmobile?

- Quite a while. 4 hours+ The engine case has to be split apart.

- Q: How do i change the wheel bearings on a four-wheel drive 96 jeep grand cherokee?

- pull the wheels first, then you will have to remove the caps on the axles ( front ones ) , there is a tool to remove the nut that holds the wheel bearings in place , you have to remove that, the brake calipers and rotors will have to come off too, the rotor has the wheel bearings inside of it, the outter and inner, , use new bearings -they usually are under 30 bucks for the front bearings, and about the same for the rear bearings, the rear bearings are on the drive axle, so you will have to pull the axles to have the rear bearings removed, and they are pressed on, so you will need to take them to a shop with a press for r/r of the wheel bearings

- Q: i have 4 wheels and when i spin 3 they sound fast and they make a roaring sound and they spin for at least 40 seconds but when i spin the last wheel it makes no sounds and it spins for atleast 20 seconds, and when i ride on my skateboard it makes a weird sound

- The okorder /

- Q: is it cheaper to fix it or replace?

- It's cheaper just to replace the pedals you can get them for $4 to $20 on line or at a bike shop.

- Q: how do theymake steel ball bearings so perfectly round and of the same size?

- check out National Geographic channel or discovery channel in your area. Got a progran called How it's made. Shows 4 different things each time it's aired and it airs couple times a day. I know for a fact they had ball bearings on there once. Done with a machine. May be on one of their websites too.

- Q: http://www.amazon .uk/Bones-Reds-Skateboard-Bearings-Red/dp/B000FDRQ1S/ref=sr_1_1?ie=UTF8qid=1377987075sr=8-1keywords=bones+redsAnd tell me if the price is good for their quality.

- These bearings are amazing for skateboarding. I bought a pack and I love them. They are well built and durable bearings for a fantastic price. I would buy them for sure.

- Q: I have a sector 9 Cosmic 2 board and one of the bearings messed up. i need to buy spare bearings. i can't find longboard bearings while skateboard bearings r easy to find. r they the same? and whats a good place to buy beartings

- yes they use the same type of bearings and you can find them from your local skate shop or you can try fixing the broken bearing by cleaning it. what i do i put wd-40 and let it run through so all the dirt comes out and they once all the dirt is out you spin the bearing until the wd-40 drys out and then you put speed cream in it. but if you buy new bearings get bones reds.

- Q: I bought the trailer today. It's in fairly good shape but its been sitting in a field for about a year. I'm going to get new tires, but before I take the trailer any distance at all, I need to repack the ball bearings on the axle. I could probably figure all this out by myself, but if anyone has any suggesions or can offer any help, I would certainly appreciate it.

- So far nobody answered your question,let me try.To repack the bearings you first have to remove the wheel and hub assy.from the axle.To do this first remove the metal cap at the center of the wheel,you will find a large nut with a cotter pin through it,remove the pin and remove the nut.The whole wheel and hub will slide off of the axle.The outer bearing will fall into your hand,the rear one wont fall out because of the rear seal.You can purchase wheel bearing grease at any auto supply store. You will now be able to see if there was water,dirt etc.inside the hub.Now you have to decide if just adding grease is enough or replacement is necessary. With your hand work the grease into the bearing and adding grease in the back of the wheel.Reassemble,when you tighten the nut back on do not over tighten,just snug,reinstall the cotter pin and replace the dust cap. Hope this helps

Send your message to us

The supply of high-quality entity ferrule needle bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords