Mullita ladrillo refractario refractarios aislantes JM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mullita ladrillo refractario refractarios aislantes JM 23

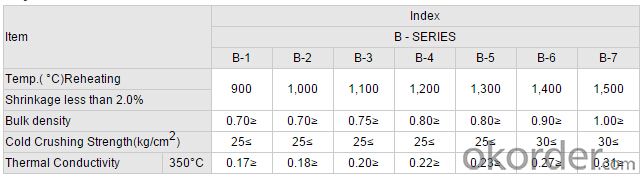

Aislamiento de calor de la serie okorder ladrillo

La serie okorder ladrillo es un eficaz aislamiento térmico, ahorro de energía, baja en carbono, la protección del medio ambiente avanzado, de acuerdo a la norma ASTM la fabricacion de productos.Okorder serie productos son mejores Li Ning y aislamiento en todo tipo de hornos industriales en el sector metalurgico, aluminio, petroquímica, energía eléctrica y materiales de cerámica de vidrio.Pueden ser utilizados como parte de la capa de aislamiento termico o non - Fusion.Los productos han sido ampliamente utilizados en el horno, logra resultados satisfactorios.

Aplicación de la preservación del calor de ladrillo

Industria metalurgica: Blast Furnace, hot alto horno, horno de calefaccion, etc.

Industria petroquímica: etileno horno horno de cracking, producción de hidrógeno, reformador primario, horno de calefaccion, etc.

Industria: horno de rodillos de cerámica, horno, etc.

Industria del vidrio: vidrio horno regenerador, etc.

Industria de carbono: carbono horno, etc.

Sector de la electrólisis de aluminio: aluminio reducción celular, etc.

Otras industrias: horno de tunel, Servicio de horno, etc.

Ventajas de ladrillo del aislamiento de calor

Baja conductividad térmica: mayor porosidad traerá buen aislamiento termico, ahorro de energía.

Alta resistencia al aplastamiento: alta resistencia al aplastamiento, la estabilidad de volumen.

Almacenamiento de calor: pequeños de almacenamiento de calor bajo para absorber más calor, ahorro de efecto es evidente.

Gao Chundu: hierro, metal alcalino de bajo contenido de impurezas.

El tamaño exacto: tamaño de ladrillo precision de procesamiento, forma especial de corte y molienda, acelerar el ladrillo.

Foto de ladrillo aislante

Problema común soluciones

1.¿Que productos tienes?

Disponemos de todo tipo de ladrillos refractarios, refractarios materiales de fundicion, mortero, cemento, productos de fibra cerámica, etc.

O usted puede hojear nuestros productos a elegir lo que usted necesita.

2.¿Cómo controlar la calidad del producto?

Con sistema de estricto control de calidad en la seleccion de materiales y el proceso de producción, tenemos la calidad de materiales refractarios y productos de fibra cerámica para satisfacer las necesidades de los clientes.

Desde la seleccion de materias primas, la calidad de nuestro control para empezar.El certificado de calidad de la materia prima es necesaria, cada lote de los productos serán probados en el uso de la línea.En el proceso de producción, el control de calidad por los trabajadores, y luego cada pieza de la clasificación, y mediante la supervisión de la calidad y la inspección.

3.¿Me puedes dar una breve introducción a la aplicación de su producto?

Mi empresa se dedica principalmente en refractarios en el acero, cemento, vidrio, cerámica, petroquímica, energía eléctrica y otras industrias.

4.¿Qué información necesitas si te necesito?

Con el fin de seleccionar los productos adecuados, que nos proporcionará la información, tales como los Estados Unidos, datos técnicos, cantidad de pedido, la aplicación del producto, etc.

Si usted tiene alguna pregunta, por favor pongase en contacto con nosotros.

- Q: What are the raw materials used in the production of insulating fire bricks?

- Insulating fire bricks are produced using a blend of alumina, silica, and assorted additives. Alumina is obtained from bauxite ore, which is then processed to extract the alumina content. Silica, on the other hand, is typically sourced from quartz or silica sand. These two substances serve as the primary constituents of insulating fire bricks, granting them exceptional heat resistance and thermal insulation properties. Supplementary to alumina and silica, additional additives may be incorporated into the manufacturing process to enhance specific characteristics of the bricks. For instance, clay can be included to improve the workability and plasticity of the mixture during shaping and molding. Various binders, such as organic or inorganic materials, can also be integrated to fortify the strength and structural integrity of the bricks. Depending on the desired qualities and specific requirements of the insulating fire bricks, other materials may be added as well. These can include zirconium, magnesium, calcium, or other refractory materials. These additives aid in further bolstering the heat resistance, mechanical strength, and insulation properties of the bricks. In summary, the amalgamation of alumina, silica, and other additives gives rise to a composition capable of withstanding high temperatures, offering excellent insulation, and exhibiting commendable structural integrity. Consequently, insulating fire bricks are highly regarded materials in various industries such as metallurgy, ceramics, and kiln construction.

- Q: Are insulating fire bricks suitable for use in steel manufacturing plants?

- Insulating fire bricks are a suitable choice for steel manufacturing plants. Their excellent thermal properties, including high heat resistance and low thermal conductivity, make them ideal for high-temperature environments like steel manufacturing plants. These bricks can endure the extreme heat generated during steel production processes such as melting, casting, and forging. Furthermore, they assist in conserving energy by minimizing heat loss, thereby enhancing the overall efficiency of the plant. Additionally, they possess considerable mechanical strength and can withstand the physical stresses and strains associated with steel manufacturing operations. In summary, incorporating insulating fire bricks in steel manufacturing plants can enhance safety, boost productivity, and improve energy efficiency.

- Q: Are insulating fire bricks resistant to fire?

- Absolutely, insulating fire bricks are resistant to fire without a doubt. These bricks are meticulously crafted and engineered to endure soaring temperatures and offer exceptional insulation properties. Made from lightweight refractory materials like ceramic fibers or expanded clay, insulating fire bricks possess low thermal conductivity and boast high melting points. Consequently, they excel at retaining heat and safeguarding against extreme temperatures. Their wide usage in furnaces, kilns, and fireplaces, where intense heat prevails, is a testament to their effectiveness. In essence, insulating fire bricks are tailor-made to be highly fire-resistant, making them an ideal choice for insulation against heat and fire prevention.

- Q: Can insulating fire bricks be used for high-temperature applications?

- Yes, insulating fire bricks can be used for high-temperature applications. These bricks are designed to withstand extremely high temperatures and provide excellent insulation, making them suitable for use in industries such as metallurgy, glassmaking, and kiln construction. They can effectively retain heat, minimize heat loss, and provide thermal protection in high-temperature environments.

- Q: How do insulating fire bricks affect the overall noise insulation of a building?

- Insulating fire bricks can significantly enhance the noise insulation of a building. These bricks have excellent sound-absorbing properties due to their high density and ability to dampen sound vibrations. By reducing the transmission of airborne and impact noises, insulating fire bricks help create a quieter and more peaceful indoor environment.

- Q: Can insulating fire bricks be cut or shaped to fit different spaces?

- Indeed, it is possible to cut or shape insulating fire bricks to suit various spaces. These bricks are crafted from lightweight materials, enabling effortless customization using ordinary tools like saws, knives, or rasps. Consequently, they can be perfectly tailored to fit fireplaces, kilns, furnaces, and other high-temperature settings. Nevertheless, it must be emphasized that caution must be exercised while cutting or shaping insulating fire bricks, as they may generate dust or debris.

- Q: Are insulating fire bricks resistant to ammonia gas?

- Yes, insulating fire bricks are generally resistant to ammonia gas. Their high temperature resistance and low thermal conductivity make them suitable for applications involving ammonia gas. However, it is always recommended to refer to the specific manufacturer's specifications and consult with experts to ensure the compatibility of insulating fire bricks with ammonia gas in a particular setting.

- Q: Can insulating fire bricks be used in high-temperature insulation blankets for aerospace applications?

- Insulating fire bricks are not typically used in high-temperature insulation blankets for aerospace applications due to their solid and rigid nature, which makes them unsuitable for flexible and conformable insulation. Instead, aerospace insulation blankets are typically made from flexible and lightweight materials like ceramic fiber or silica fiber. These materials offer excellent thermal insulation properties and can easily mold and shape to fit complex geometries. They provide effective heat insulation and protection for critical components. Additionally, insulation blankets in aerospace applications must meet stringent requirements such as low outgassing, high thermal stability, and resistance to vibration and mechanical stress. Insulating fire bricks may not satisfy these specific requirements and may not withstand the extreme conditions in aerospace environments. In conclusion, while insulating fire bricks excel in certain high-temperature insulation applications, they are not appropriate for aerospace insulation blankets. The aerospace industry demands insulation materials that are flexible, lightweight, and high-performing, capable of conforming to intricate shapes and enduring the unique challenges of this sector.

- Q: Can insulating fire bricks be cut or shaped using common tools?

- Indeed, common tools can be utilized to cut or mold insulating fire bricks. These bricks are typically composed of lightweight refractory substances like clay and minerals, making them more amenable to cutting and shaping than conventional fire bricks. To achieve the desired dimensions and design, one can employ basic tools such as a handsaw, angle grinder, or even a chisel and hammer. However, it is crucial to prioritize safety when handling insulating fire bricks by donning protective gear like gloves, goggles, and a dust mask. This precautionary measure is necessary to avert any potential health risks.

- Q: Can insulating fire bricks be used for pizza ovens?

- Yes, insulating fire bricks can be used for pizza ovens. Insulating fire bricks are designed to withstand high temperatures, making them a suitable choice for creating a well-insulated and efficient pizza oven. They help retain heat, allowing the oven to reach and maintain the desired temperature for baking delicious pizzas.

Send your message to us

Mullita ladrillo refractario refractarios aislantes JM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords