Ac Aluminum Coil Oxidation Mirror Finish Aluminium Coil for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mirror Finish Aluminium Coil for Building Materials

l Product Information

1. Alloy: 1100, 1145, 1050, 1060, 1070, 3003, 3105, 3A21, 3005, 3105, 3A21, 5052,5754,5082, 5083, 5182,5A03, 6063,6061,6082,8011 |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payment.

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is a popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality aluminium coil to the world.

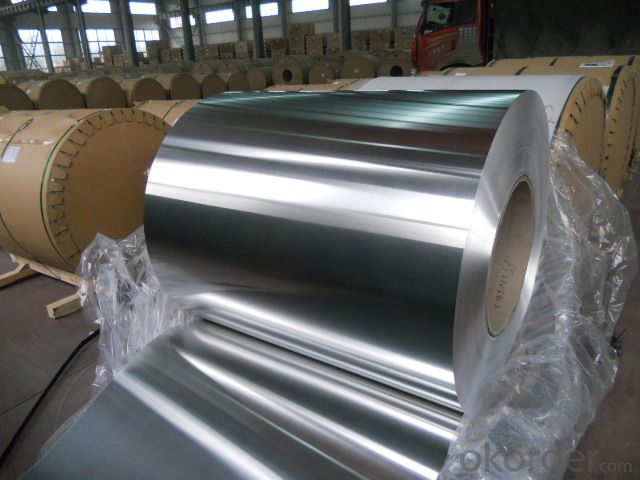

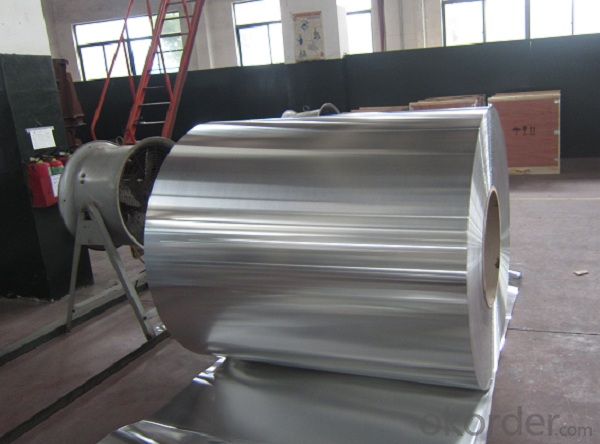

l Product Images

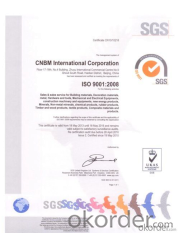

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Can aluminum coils be used in the production of aluminum composite doors?

- Aluminum composite doors can indeed incorporate aluminum coils. These doors are crafted by sandwiching a core material between two aluminum sheets. The core material can consist of various substances, such as polyethylene or fire-resistant minerals. There are several benefits to using aluminum coils in the manufacturing of aluminum composite doors. Firstly, aluminum is a lightweight substance, rendering the doors easier to handle and install. Secondly, aluminum boasts exceptional resistance to corrosion, guaranteeing the doors' longevity and durability. Moreover, aluminum coils can be manipulated and molded with great ease, allowing for the creation of personalized designs and styles. The utilization of aluminum coils in the production of aluminum composite doors further provides flexibility in terms of color choices. Aluminum can be powder coated or painted in a myriad of hues, enabling a broad spectrum of options to cater to diverse architectural styles and individual preferences. In conclusion, aluminum coils are a fitting and widely employed material in the fabrication of aluminum composite doors due to their lightweight nature, resistance to corrosion, and customizable properties.

- Q: What are the potential applications of coil-brushed aluminum coils?

- Due to its unique properties, coil-brushed aluminum coils have a wide range of potential applications. Here are several examples: 1. Architectural projects can benefit from the use of coil-brushed aluminum coils. These coils can be utilized for building facades, roofing, cladding, and decorative elements, adding a sophisticated and modern look to structures. 2. In the field of interior design, coil-brushed aluminum coils can be used for wall paneling, ceiling tiles, partition screens, and decorative accents. The brushed texture provides a sleek and stylish appearance, making them suitable for residential, commercial, and hospitality settings. 3. Coil-brushed aluminum coils can be incorporated into furniture designs, including tables, chairs, shelves, and cabinets. The brushed finish adds a contemporary touch to the furniture pieces, making them suitable for modern and minimalist styles. 4. The lightweight and corrosion-resistant nature of aluminum make it an ideal material for automotive applications. Coil-brushed aluminum can be used in the manufacturing of interior trim, dashboards, door panels, and other decorative components in cars, trucks, and motorcycles. 5. The excellent conductivity and heat dissipation properties of coil-brushed aluminum make it suitable for the production of electronic devices such as smartphones, laptops, and tablets. The brushed finish adds a premium feel to these products. 6. Coil-brushed aluminum coils are also useful in the manufacturing of signage and branding elements. The brushed texture enhances the visibility and aesthetics of the signs, making them stand out and convey a sense of quality and professionalism. 7. In the kitchenware and appliances industry, coil-brushed aluminum is a popular choice due to its durability, heat resistance, and easy cleaning properties. It can be used to produce cookware, bakeware, kitchen utensils, and appliance panels, providing a sleek and modern look. 8. Coil-brushed aluminum coils are also utilized in the production of packaging and labeling materials. The brushed finish adds an elegant touch to product packaging, making it visually appealing and attractive to consumers. In conclusion, coil-brushed aluminum coils have a wide range of potential applications in various industries, including architecture, interior design, automotive, electronics, kitchenware, signage, and packaging. Their unique properties make them versatile and desirable for different projects.

- Q: Can aluminum coils be used in packaging industries?

- Yes, aluminum coils can be used in packaging industries. Aluminum is lightweight, flexible, and has excellent barrier properties that protect the packaged products from moisture, oxygen, and light. It is commonly used for packaging food, beverages, pharmaceuticals, and other consumer goods due to its durability and ability to preserve product quality.

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for pharmaceutical packaging due to its various beneficial properties. It is lightweight, corrosion-resistant, and has excellent barrier properties, making it ideal for protecting pharmaceutical products from external factors such as moisture, oxygen, and light. Aluminum coils can be easily formed into different shapes and sizes, providing versatility for packaging needs. Additionally, aluminum is non-toxic and non-reactive, ensuring the safety and integrity of pharmaceutical products.

- Q: Is it possible to recycle aluminum coils without any loss in their quality?

- <p>Yes, aluminum coils can be recycled without damaging their quality. Aluminum is one of the most recycled materials due to its ability to be recycled indefinitely without any loss in quality. The recycling process involves melting the aluminum, which can then be reshaped into new coils or other products. This process is energy-efficient and environmentally friendly, as it requires significantly less energy than producing aluminum from raw materials. Recycled aluminum maintains the same strength, durability, and appearance as new aluminum, making it a sustainable choice for various applications.</p>

- Q: How do aluminum coils compare to nickel coils in terms of conductivity?

- Compared to nickel coils, aluminum coils typically exhibit lower electrical conductivity. This is mainly attributable to the fact that aluminum has a higher resistivity than nickel. Concerning conductivity, nickel emerges as a superior electrical conductor owing to its lower resistivity. Consequently, nickel coils are frequently favored in situations where high conductivity is vital, like in electrical circuits or heating elements. Nonetheless, it is crucial to acknowledge that aluminum coils still possess reasonable conductivity and may prove suitable for specific applications where cost-effectiveness or lightweight properties outweigh other considerations.

- Q: How are aluminum coils tested for surface hardness?

- Aluminum coils are typically tested for surface hardness through a variety of methods, including the use of a hardness tester or durometer. These instruments measure the resistance of the coil's surface to indentation or penetration by applying a specific amount of force. The results are then compared to a standardized scale to determine the surface hardness of the aluminum coil.

- Q: Is it possible to use a grinder for cutting aluminum coil?

- <p>Yes, you can use a grinder to cut aluminum coil, but it's essential to choose the right type of grinder and blade. A metal cutting grinder with a suitable blade designed for cutting aluminum is recommended. Ensure the blade is sharp and the grinder is powerful enough to handle the material. Always wear appropriate safety gear, including gloves and eye protection, as cutting aluminum can produce sharp edges and flying debris. Be cautious of the heat generated during cutting, as it can warp or damage the aluminum.</p>

- Q: What is the maximum coil weight that can be produced?

- Several factors, including the type of material being coiled, the size and capacity of the coiling equipment, and the strength and durability of the coil itself, determine the maximum weight of a coil that can be produced. Generally, the maximum weight of a coil can vary from a few pounds to several tons. However, it is important to consider that exceeding the recommended maximum weight of a coil can result in safety hazards, equipment damage, and compromise the quality and integrity of the coil. Therefore, it is crucial to refer to the manufacturer's guidelines and specifications to ascertain the maximum weight of a coil that can be safely and effectively produced for a specific application.

- Q: Can aluminum coils be embossed or textured?

- Aluminum coils possess the capability to undergo embossing or texturing, thereby enabling the creation of patterns or designs on their surface. This can be achieved through mechanical or chemical processes. The resulting embossed or textured surface not only enhances the visual appeal but also improves the functionality of the aluminum coil, by augmenting its grip or minimizing glare. Consequently, these aluminum coils, with their embossed or textured features, have found widespread utilization across industries like construction, automotive, and packaging.

Send your message to us

Ac Aluminum Coil Oxidation Mirror Finish Aluminium Coil for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords