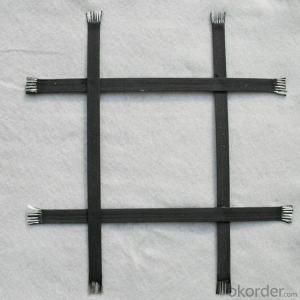

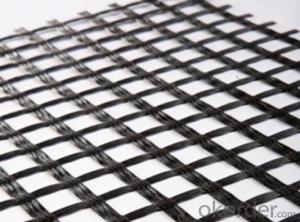

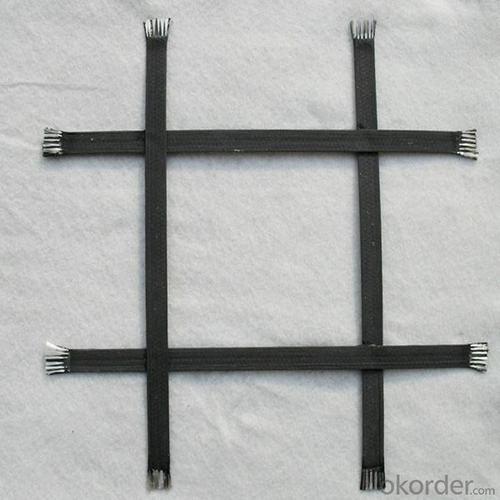

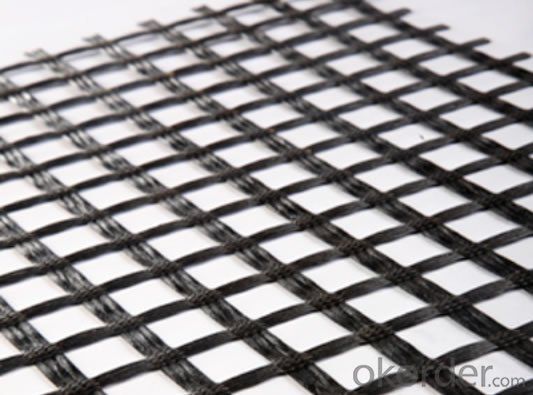

Miragrid Gx Reinforcement and Separation Geogrids for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

OEM or Road

Model Number:

EGA50-50, EGA80-80, EGA100-100

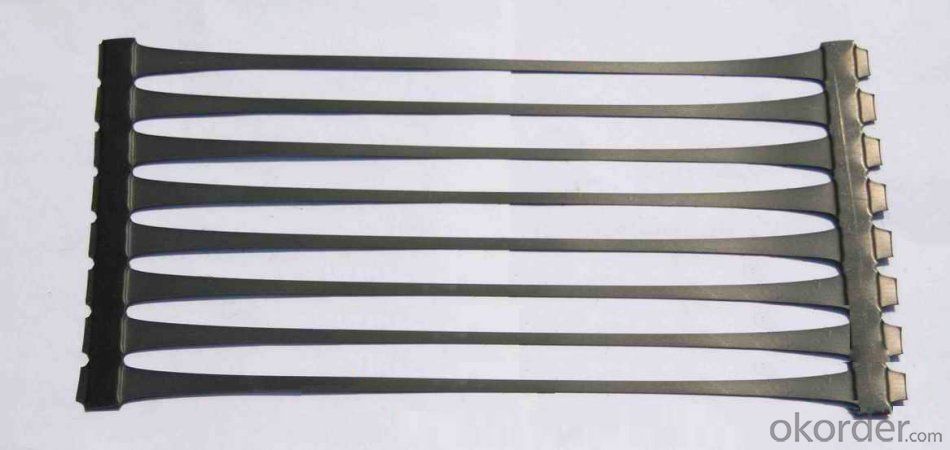

Uniaxial geo grids typically have their tensile strength in the machine (roll) direction. They are mainly used to reinforce the soil mass in a steepened slope or segmental retaining wall. On occasion, they function as a wrapping to confine the aggregate in the wire forms of welded wire faced steepened slopes.

Our niaxial geogrids are made from polyester yarn, knitted or woven into a stable structure and have a PVC or polymeric coating. These flexible, user-friendly geogrids are inert to biological degradation and resistant to creep, strain and naturally found chemicals.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in riverbank protection projects?

- Yes, geogrids can be used in riverbank protection projects. Geogrids provide reinforcement and stability to the soil, preventing erosion and slippage along the riverbank. They are effective in enhancing the strength of the soil while allowing for proper drainage. Geogrids can be installed easily and are a cost-effective solution for protecting riverbanks against erosion and maintaining their stability.

- Q: Can geogrids be used in erosion control blankets?

- Yes, geogrids can be used in erosion control blankets. Geogrids are commonly used as reinforcement materials in erosion control applications to provide additional strength and stability to the blanket, preventing soil erosion and promoting vegetative growth.

- Q: Can geogrids be used for load distribution?

- Yes, geogrids can be used for load distribution. Geogrids are synthetic materials that are used in a variety of civil engineering applications to reinforce soil and distribute loads. They are commonly used in road construction, retaining walls, and slope stabilization projects to enhance the structural integrity of the soil and spread the load more evenly.

- Q: How do geogrids improve the performance of mechanically stabilized slopes during seismic events?

- Geogrids improve the performance of mechanically stabilized slopes during seismic events by providing additional reinforcement and enhancing the stability of the slopes. They act as a tension element, distributing and transferring the seismic forces throughout the slope, thereby reducing the potential for slope failure and displacement. Geogrids also increase the strength and stiffness of the soil, improving its resistance to shear and lateral movement caused by seismic shaking. Overall, geogrids enhance the structural integrity of mechanically stabilized slopes, making them more resistant to seismic events.

- Q: What are the specifications and models of Geotextiles and geogrids on the highway

- You are production, or sales, or procurement, the question asked, what kind of model is determined by the designer

- Q: Can geogrids be used in retaining walls for recreational areas?

- Yes, geogrids can be used in retaining walls for recreational areas. Geogrids are commonly used in retaining walls to reinforce and stabilize the soil, providing additional strength and stability to the structure. This is particularly important in recreational areas where safety is a priority, as geogrids help prevent soil erosion and potential collapse of the retaining wall.

- Q: What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one primary direction, typically in the machine direction. This means they provide reinforcement in one direction only. On the other hand, biaxial geogrids have strength and stiffness in both the machine direction and cross-machine direction, providing reinforcement in two perpendicular directions.

- Q: Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids are commonly used in civil engineering projects to improve the stability and strength of weak soil or subgrade. They help distribute load and reduce settlement, preventing soil deformation and enhancing overall performance. Geogrids effectively reinforce soft subgrades by confining the soil particles and increasing their shear resistance, resulting in improved stability and reduced risks of failure.

- Q: How to determine the number of geogrid detection method

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.3) fill: after the completion of the grille, should be timely (48 hours) filling. Each layer should be carried out according to the principle of "the first two sides, the middle of the back". The packing is not allowed to be unloaded directly on the geogrid. It must be unloaded on the soil surface which has been paved. The soil unloading height is not more than 1m. All vehicles and construction machinery shall not be allowed to walk directly on the paved geogrid, but only to be allowed to travel along the axis of the embankment.4) the upper and lower sides of the geogrid, and 8 cm from the grid layer shall not be more than 6 cm in diameter.

- Q: What are the design considerations for geogrids in mechanically stabilized earth walls?

- Some of the key design considerations for geogrids in mechanically stabilized earth (MSE) walls include selecting the appropriate geogrid material and strength, determining the required geogrid spacing and length, considering the connection and anchorage details, assessing the interface friction between the geogrid and the soil, and evaluating the long-term durability and performance of the geogrids in the specific environmental conditions. Additionally, proper installation practices and quality control measures should be implemented to ensure the geogrids are correctly positioned and tensioned within the MSE wall system.

Send your message to us

Miragrid Gx Reinforcement and Separation Geogrids for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords