Mill Finished Aluminum Two Bars Treadplate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Two Bars Aluminium Treadplate Description

Mill Finished Two Bars Aluminium Treadplate is one semi-finished aluminium material. This plate can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Two Bars Aluminium Treadplate

Mill Finished Two Bars Aluminium Treadplate | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Two Bars Aluminium Treadplate

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Two Bars Aluminium Treadplate

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Two Bars Aluminium Treadplate

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

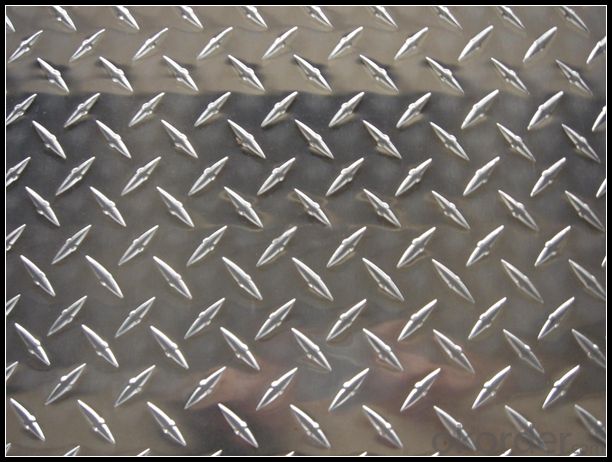

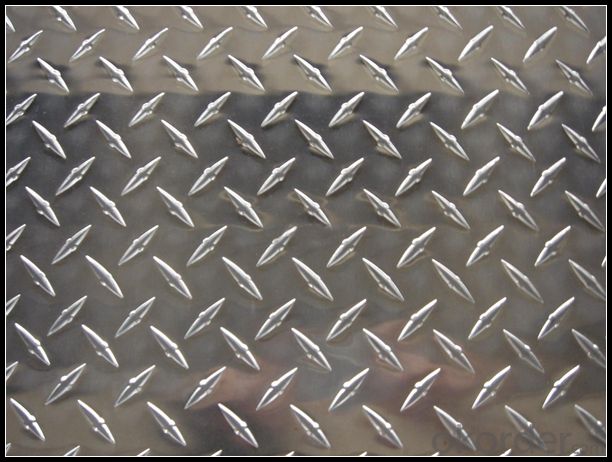

6. Image of Mill Finished Two Bars Aluminium Treadplate

7. Package and shipping of Mill Finished Two Bars Aluminium Treadplate

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks about the impact of adding silicon to aluminum alloys on their characteristics.

- <p>Adding silicon to aluminum alloys significantly enhances their properties. Silicon increases the alloy's strength and hardness, making it more durable. It also improves the alloy's resistance to corrosion, particularly in harsh environments. The addition of silicon can also reduce the melting point of the alloy, which can be beneficial for casting processes. However, it should be noted that excessive silicon content can lead to a decrease in ductility and workability of the alloy. Overall, silicon is a common alloying element used to improve the mechanical properties and performance of aluminum alloys in various applications.</p>

- Q: How can we decrease our reliance on aluminum in everyday life?

- <p>Yes, there are several ways to reduce the use of aluminum in daily life. Opt for glass, ceramic, or stainless steel containers instead of aluminum ones. Choose wooden or bamboo utensils over aluminum ones. When possible, select products with minimal aluminum packaging. Avoid non-stick cookware, as it often contains aluminum. Use a cast iron or glass baking sheet instead of aluminum foil in the oven. Educate yourself on the presence of aluminum in everyday products and make conscious choices to reduce exposure.</p>

- Q: Is it possible to use pure aluminum to create tools and equipment with increased longevity?

- <p>Pure aluminum is not typically used for making tools and equipment that require durability and strength. While it is lightweight and corrosion-resistant, pure aluminum is relatively soft and lacks the strength needed for most tools and equipment. Alloys of aluminum, which combine aluminum with other elements like copper, magnesium, or silicon, are often used instead. These alloys offer improved strength, hardness, and wear resistance, making them more suitable for long-lasting tools and equipment.</p>

- Q: Is it possible to create jewelry using aluminum as the primary material?

- <p>Yes, aluminum can be used to make jewelry. It is a lightweight, durable, and affordable metal that is often used in costume jewelry and fashion accessories. Aluminum's low cost and ease of shaping make it a popular choice for designers looking for a versatile material that can mimic the look of more expensive metals. However, it is not as strong or valuable as precious metals like gold or silver, and it may not be suitable for fine jewelry due to its lower durability and potential for oxidation.</p>

- Q: What are the positive environmental impacts associated with the use of aluminum?

- <p>Aluminum offers several environmental benefits. It is highly recyclable, which means it can be reused multiple times without losing its properties, reducing the need for raw materials and the energy required for extraction and processing. Aluminum is also lightweight, which can reduce fuel consumption and emissions in transportation. Additionally, aluminum is a good conductor of heat and electricity, making it energy-efficient in various applications such as insulation and electrical wiring. Its durability and resistance to corrosion mean it lasts longer, reducing waste and the need for frequent replacements.</p>

- Q: The question seeks to understand the steps involved in producing aluminum, from raw material extraction to the final product.

- <p>The process of aluminum production involves several key steps. Initially, bauxite, the primary aluminum ore, is mined. This ore is then crushed and washed to remove impurities. The next phase is the Bayer Process, where bauxite is dissolved in a caustic soda solution under high temperature and pressure, resulting in a solution rich in aluminum hydroxide. This solution is then seeded with aluminum hydroxide crystals, causing more crystals to form, which are then harvested. The final step is the Hall-H茅roult Process, where the aluminum oxide is dissolved in a molten cryolite bath and electrolyzed to extract pure aluminum. This process involves passing an electric current through the bath, causing aluminum ions to be reduced at the cathode, forming molten aluminum which is then tapped off for further processing or use.</p>

- Q: What are the various applications and benefits of using aluminum in the automotive industry?

- <p>Aluminum is widely used in automobiles for its lightweight properties, which improve fuel efficiency and reduce emissions. It's used in engine parts, such as pistons and cylinder heads, to decrease weight and increase performance. Aluminum is also used in body panels, wheels, and suspension components, enhancing vehicle handling and reducing unsprung weight. Additionally, aluminum's corrosion resistance makes it ideal for exterior parts, and its recyclability aligns with environmental sustainability efforts in the automotive industry.</p>

- Q: Is it possible to utilize aluminum as a material for food containers?

- <p>Yes, aluminum is commonly used to make food containers due to its lightweight, durability, and good thermal conductivity. It's important to note that aluminum containers are often coated or lined with materials like plastic or enamel to prevent direct contact with food, as aluminum can react with acidic or alkaline foods and potentially leach into the food. Additionally, while aluminum is generally safe, there are concerns about its long-term health effects, so its use in food containers is regulated to ensure safety.</p>

- Q: This question asks for an overview of the various types of aluminum alloys that exist.

- <p>Aluminum alloys are categorized into several series based on their primary alloying elements. The main types include: 1. 1xxx series: Pure aluminum alloys with 99.00% minimum aluminum content. 2. 2xxx series: Aluminum-copper alloys, known for their high strength. 3. 3xxx series: Aluminum-manganese alloys, which offer good formability and moderate strength. 4. 4xxx series: Aluminum-silicon alloys, used for welding wire and filler materials. 5. 5xxx series: Aluminum-magnesium alloys, characterized by good formability and corrosion resistance. 6. 6xxx series: Aluminum-silico-magnesium alloys, known for their high strength and excellent machinability. 7. 7xxx series: Aluminum-zinc-magnesium alloys, which are the strongest and most widely used in the aerospace industry. These alloys have various applications based on their unique properties, such as strength, corrosion resistance, and formability.</p>

- Q: Describe the key differences between aluminum and stainless steel in terms of their properties and uses.

- <p>Aluminum and stainless steel are both metals with distinct properties. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, making it ideal for applications like beverage cans, aircraft parts, and electrical wiring. It is also non-magnetic and has a lower melting point compared to steel. Stainless steel, on the other hand, is an alloy that contains chromium and is known for its strength, durability, and resistance to staining and corrosion. It is commonly used in cutlery, appliances, and construction materials. Stainless steel is heavier, stronger, and more resistant to high temperatures than aluminum.</p>

Send your message to us

Mill Finished Aluminum Two Bars Treadplate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords