High Quality Aluminum Coils - Mill Finished Aluminum Treadplate with Big Five Bar Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Aluminium Treadplate of Big Five Bar Pattern Description

Mill Finished Aluminium Treadplate of Big Five Bar Pattern is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

Mill Finished Aluminium Treadplate of Big Five Bar | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

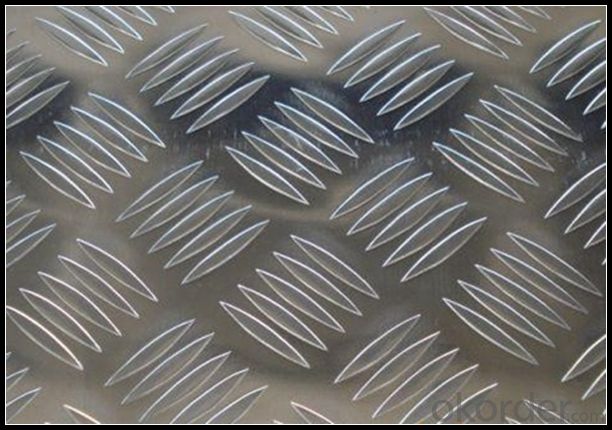

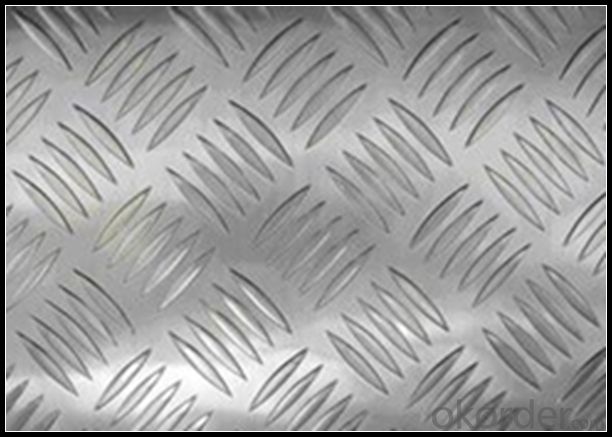

6. Image of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

7. Package and shipping of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils joined together to form larger panels?

- Coil joining or coil-to-panel joining is the technique employed to combine aluminum coils into larger panels. To accomplish this, aluminum coils are fed into a coil joining machine, specifically designed for seamless connection of multiple coils. To initiate the process, the individual coils are inserted into the machine. The machine then unwinds the coils and brings them together, aligning them side by side. Typically, the edges of the coils slightly overlap to ensure a secure and uninterrupted connection. Once aligned, the machine implements various methods to bond the coils together. One prevalent approach involves the application of heat and pressure. By heating the overlapping edges of the coils, the aluminum softens and fuses together. Simultaneously, pressure is applied to ensure a robust bond. Alternatively, mechanical fasteners can be utilized to join the aluminum coils. In this case, the machine punches holes through the overlapping edges and inserts fasteners, such as screws or rivets, for a secure hold. Following the joining process, the machine continues to feed the connected coils forward, facilitating continuous production of larger panels. Excess material from the overlapping edges is typically trimmed off, resulting in a sleek and seamless panel. Overall, precision and specialized machinery are essential for the process of joining aluminum coils to create larger panels. The resulting panels possess durability, lightweight properties, and find widespread application in industries such as construction, automotive, and aerospace.

- Q: How much of a difference does it make? I recently bought a 700 SPS tactical in 308. It has the Houge pillar bedding stock. I love the tacky feeling rubber outside, but noticed that the fore end of the stock flexes a bit (enough to touch the free floating barrel.) I was wondering if the aluminum bedding block version of the same stock (or any other aluminum bedding stock) will be better? I know they cost more, and the experts claim they're great, but will an amateur shooter notice the difference? I like to target shoot, typically around 200 yards. BTW, I was also considering the Bell and Carlson medalist.

- Vote for the Aluminum yet somewhat might like a silver lined one bless by using a Catholic priest that emits holy water. That way in case they are additionally a vampire you nailed them.

- Q: Would an SS scribe scratch an aluminum plate? What is the hardness value of both metals?

- SS and aluminium are available in very many shape and sizes SS is very much harder than aluminium aluminium has a hardness of 28 SS 90 to 100 Guru

- Q: How are aluminum coils protected from damage during transportation?

- Aluminum coils are protected from damage during transportation through a combination of packaging materials and handling precautions. Firstly, the coils are typically wrapped with protective materials such as stretch film or plastic wrap to prevent scratches and abrasions. This helps to maintain the integrity of the coil surface and prevent any potential damage. In addition to the outer wrapping, the coils are often placed on sturdy wooden pallets or skids to provide a stable base for transportation. This helps to minimize any movement or shifting during transit, which could otherwise lead to dents or deformations in the coils. Furthermore, coils may be secured using steel or plastic strapping to further ensure their stability and prevent any unintended unwrapping or unrolling. These straps are tightly fastened around the coils and pallets, creating a secure bundle that can withstand the potential jostling and vibrations that occur during transportation. During loading and unloading, specialized equipment such as forklifts or cranes are used to handle the coils with care. This minimizes the risk of dropping or mishandling, which could cause significant damage to the coils. Overall, a combination of protective packaging materials, secure pallets, and careful handling procedures are employed to safeguard aluminum coils from damage during transportation. These measures aim to preserve the quality and structural integrity of the coils, ensuring that they arrive at their destination in optimal condition.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: Why does the coated aluminum coil have thickness requirement for membrane?

- The purpose of coating is to protect the surface of aluminum coil and make it more aesthetic. The thickness of membrane is closely related to the keep years of products made by aluminum coil.

- Q: Are aluminum coils fire-resistant?

- Aluminum coils possess fire-resistant qualities due to their high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and their inability to burn, rendering them non-combustible. This specific characteristic allows for the utilization of aluminum coils in various applications, particularly in sectors where fire resistance is of utmost importance, such as building construction, electrical wiring, and HVAC systems. Moreover, the remarkable heat conductivity of aluminum facilitates rapid heat dissipation, thereby minimizing the risk of fire incidents. Nevertheless, it is crucial to acknowledge that although aluminum coils themselves exhibit fire-resistant properties, they may be incorporated into systems alongside other components that might not share the same level of fire resistance. Consequently, it is essential to consider the entirety of the system and adhere to proper fire safety regulations and guidelines to ensure comprehensive fire safety precautions.

- Q: Can aluminum coils be coated with protective films?

- Yes, aluminum coils can be coated with protective films. These films provide a layer of protection against scratches, corrosion, and other damage, helping to prolong the lifespan and enhance the appearance of the aluminum coils.

- Q: i came across marine grade aluminum (grade 6082), somebody was telling it is a special grade, i checked in internet, there is nothing specific in marine grade 6082, every manufacturer can produce it. please clarify. thanks

- Marine grade means a specific alloy that resists corrosion, and does not deform easily. Alloys in the 5000 series as well as some 6000 are considered marine grade.

- Q: Is it possible to use aluminum coils in the creation of toys or games for children?

- <p>Yes, aluminum coils can be used to make toys or games for children, but safety considerations must be taken into account. Aluminum is a lightweight, durable, and non-toxic material, making it suitable for various applications, including children's toys. However, it's crucial to ensure that any aluminum used in toys is properly treated to prevent sharp edges or small parts that could pose a choking hazard. Additionally, the toys or games should be designed and manufactured to meet safety standards and regulations to protect children from potential harm.</p>

Send your message to us

High Quality Aluminum Coils - Mill Finished Aluminum Treadplate with Big Five Bar Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords