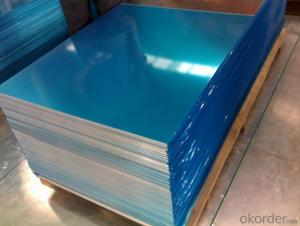

Mill-Finished Aluminum Sheets 1xxx - Aluminum Sheets Saint Paul Mn

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

alloy | Thickness(mm) | Width(mm) | Length(mm) | temper |

1100-8011 | 0.16-8.0mm | 20-2300mm | no limitation | O,H12,H14,H16,H18,H24.....H112 |

2.Mechanical Property:

alloy | Tensile strength(MPa) | Yield strength | Elongation(%) |

1100-8011 | 125~165 | 110 | 2~5 |

2.Chemical Composition:

alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

8011 | 0.50~0.9 | 0.60~1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | 0.08 | spare |

8011A | 0.40~0.8 | 0.50~1.0 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.05 | spare |

| name | 2012 newest the coated Alumiunum sheets/plates 3105/1050/1060/1100 |

| temper | O-H112 |

| type | plate |

| advantages | excellent quality,good credit competitive price,comfortable service Samples for free fast delivery,small order accepted Good rust resistance clean, flat, no wrinkle, no scratch, oil free. |

| package | Standard seaworthy exporting carton, Wooden pallets,waterproof paper and plastic coverage or or as per customer's requirements |

| Kindly attention | specifications can be customized as customer's requirements |

- Q: Can aluminum sheet be painted?

- Certainly, painting aluminum sheet is possible. However, it is crucial to adequately prepare the surface beforehand to guarantee strong paint adhesion and long-lasting results. Typically, this involves thoroughly cleaning the aluminum sheet to eliminate any dirt, grease, or oxidation. Subsequently, a primer is applied to enhance adhesion. Once the primer has dried, you can proceed with applying your desired paint. For optimal outcomes, it is recommended to select a high-quality paint suitable for metal surfaces. Moreover, if the aluminum sheet will be exposed to outdoor conditions, it is advisable to utilize a paint specifically designed for exterior use. This will ensure protection against weathering and corrosion.

- Q: What is an aluminium plate? What is the difference between carbon steel sheet, galvanized sheet and stainless steel plate?What is the order of the price? Thank you

- It is aluminized sheet, which is mainly resistant to high temperature than galvanized sheet

- Q: I am using Reeves Acrylic Colour Set and I plan on painting on Heavy Duty Ralphs Brand Aluminum Foil. Will the paint be able to go on the foil well? Tips? Thank you.

- i use aluminum foil to mix colors on and when it dries it DOES stick, however, it will scratch off really easy. just try experimenting. what do u need the foil for? maybe you can try the aluminum foil leaves? the flakes that you put ontop on the art instead of under it. that way you can glue it on and dont have to worry about it scratching off. foil looks beautiful on paintings :) how it turns out great

- Q: I need some aluminum sheets for an art project. I'm not sure where to find such a thing, though. I've looked at Home Depot briefly and aluminum flashing is the closest thing I've found. Flashing comes in a roll and is just a bit too thin. I need flat sheets of aluminum that are somewhat stiff, but not more than, say, 1/4 thick. Are there any stores that sell such things? A larger sheet would be fine if I could either get it cut at the store or find some way to cut it to the size I want. How do you cut aluminum, anyway? Any suggestions are greatly appreciated!

- For sheets of aluminum I always go to a Commercial print shop. they use large sheets of aluminum for printing posters and things. It will have some kind of printing on one side but they can tell u what to use to remove it. It is fairly cheep. I usually pay scrap aluminum price for it I is thick enough to use for craft projects or even like I did made homemade shingles to reroof my house with. Took me 2 winters to make enough shingles. To cut it just lay a straight edge and scribe it with a sharp instrument. and it will break clean..

- Q: This question asks for methods to ensure that the connections between aluminum sheets are both secure and resistant to water leakage.

- <p>To ensure that the joints between aluminum sheets are secure and watertight, use a combination of sealants and appropriate fasteners. First, clean the surfaces to be joined thoroughly. Apply a high-quality, waterproof sealant along the joint. This sealant should be compatible with aluminum and resistant to UV, temperature changes, and water. Then, use corrosion-resistant fasteners such as stainless steel screws or rivets to join the sheets. Ensure that the fasteners are tightened correctly to prevent leaks. Additionally, consider using a gasket or a weatherstrip along the joint for added watertightness. Regularly inspect and maintain the joints to ensure ongoing watertight integrity.</p>

- Q: What safety measures should be taken into account when installing aluminum sheets?

- <p>When installing aluminum sheets, it's important to follow safety precautions. Always wear appropriate personal protective equipment, including gloves and safety glasses. Ensure the work area is clear of debris and other hazards. Use the correct tools for cutting and handling aluminum sheets to prevent injuries. Be cautious of sharp edges and corners that can cause cuts. Ensure the aluminum sheets are properly secured to avoid them falling and causing harm. Follow all manufacturer guidelines for installation to ensure the stability and longevity of the aluminum sheets.</p>

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable metal, which means it can be easily shaped and bent without fracturing or breaking. However, the degree of bendability may vary based on the thickness and alloy composition of the aluminum sheet.

- Q: This question asks for a list of various methods used to treat the surface of aluminum sheets to improve their properties or appearance.

- <p>There are several types of surface treatment for aluminum sheets, each serving different purposes. These include: Anodizing, which creates a protective oxide layer and enhances corrosion resistance; Chemical Conversion Coating, such as chromate conversion, to improve paint adhesion and corrosion resistance; Electrolytic Polishing, which provides a smooth, shiny surface; Powder Coating, an electrostatic process that applies a durable coating; Paint Coating, offering a wide range of colors and finishes; and Mechanical Polishing, which smooths the surface and improves reflectivity. Each treatment has its specific applications and benefits, depending on the desired outcome for the aluminum sheet.</p>

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. It is a popular choice for roofing due to its lightweight, durability, corrosion resistance, and ability to withstand harsh weather conditions.

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- Gluing Aluminum

Send your message to us

Mill-Finished Aluminum Sheets 1xxx - Aluminum Sheets Saint Paul Mn

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords