Mill Finished Aluminum Coil Plate for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

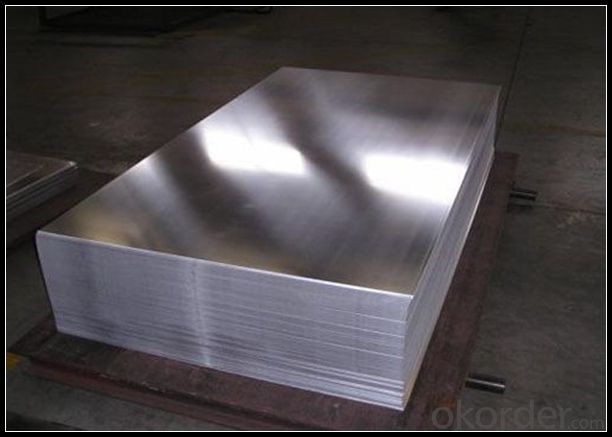

1. Structure of Mill Finished Aluminium Sheet for Punching Description

Mill Finished Aluminium Sheet for Punching is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet for Punching

Mill Finished Aluminium Sheet for Punching | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Sheet for Punching

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet for Punching

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet for Punching

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

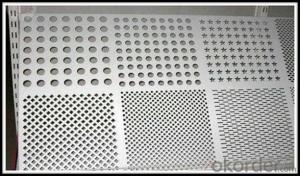

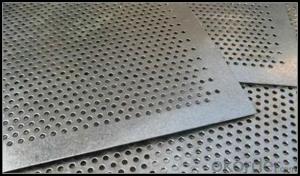

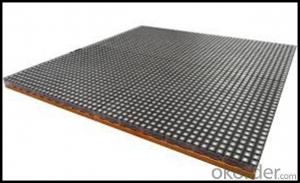

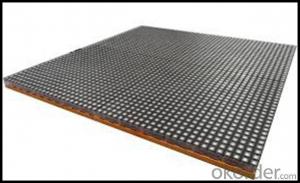

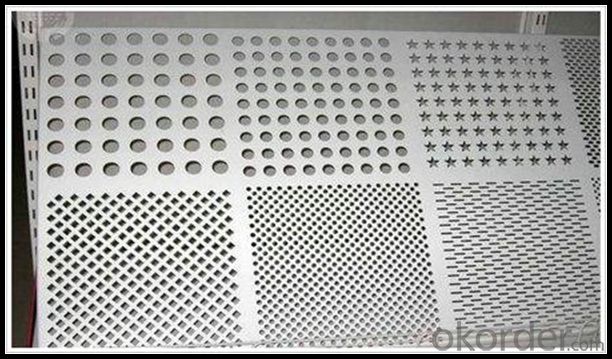

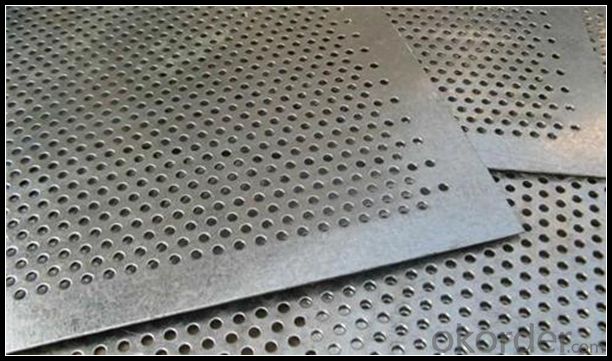

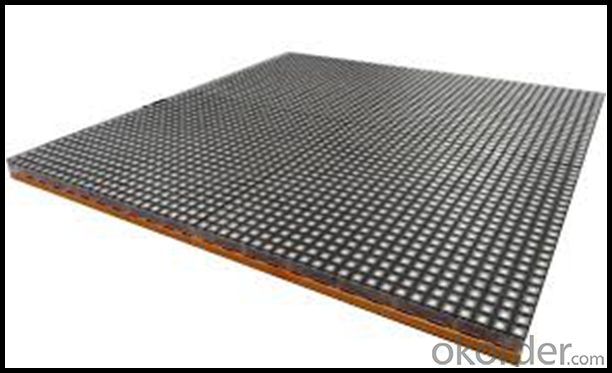

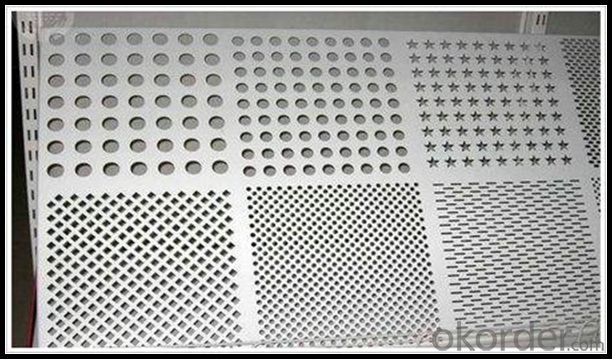

6. Image of Mill Finished Aluminium Sheet for Punching

7. Package and shipping of Mill Finished Aluminium Sheet for Punching

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the transportation and storage requirements for aluminum coils?

- There are several factors that determine the transportation and storage requirements for aluminum coils. Firstly, it is crucial to handle the coils with caution during transportation in order to avoid any harm. Secure packaging is necessary to prevent potential scratches, dents, or deformation. Additionally, safeguarding the coils from moisture is essential as exposure to water or high levels of humidity can result in corrosion. During transportation, it is advisable to employ appropriate vehicles or containers that can sufficiently support the weight and dimensions of the aluminum coils. The coils should be firmly secured to prevent any movement or shifting that may cause damage. Regarding storage, it is of utmost importance to store aluminum coils in an area that is clean, dry, and well-ventilated. Ideally, the storage facility should maintain a stable temperature and humidity level to prevent any negative effects on the coils. If the coils are stored outside, they should be adequately covered and protected from direct sunlight, rain, and other weather conditions. Furthermore, it is crucial to store aluminum coils away from any substances or chemicals that may cause damage. They should be stored in a manner that prevents contact with other materials, as physical contact can lead to scratching or other types of damage. In summary, the transportation and storage requirements for aluminum coils involve careful handling, protection from moisture and corrosive materials, proper packaging and securing during transportation, and storage in a clean and suitable environment. By adhering to these guidelines, the integrity of the aluminum coils can be preserved, ensuring their quality and usability.

- Q: Is there any specific legislation or rules governing the use of aluminum coils in public areas?

- <p>There are no universal special regulations for using aluminum coils in public places. However, regulations can vary by country, state, or even city. In some cases, building codes or safety regulations might dictate the use of certain materials, including aluminum coils, in construction or other applications within public spaces. It's important to check local regulations and guidelines to ensure compliance when using aluminum coils in public areas.</p>

- Q: Aluminum is a transition metal, woudn't the stock naming system apply to this formula?

- For the best answers, search on this site okorder

- Q: Please tell me the the size of the piece of aluminum that you give the weight messurements.

- aluminums gravity is 2.70 and weighs 1.423 troy ozs per cubic inch a note specific gravity of any metal or alloy is weight in grams of one cubic centimeter. also most metals use troy weights and to find troy weight of one cubic inch of any metal or alloy multiply specific gravity by a constant of 0.52686

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: This question is asking about the potential negative effects or hazards associated with the use of aluminum coils.

- <p>The use of aluminum coils can pose certain risks and dangers, primarily due to their high thermal conductivity and reactivity. When used in cooking or heating applications, aluminum coils can cause uneven heat distribution, which may lead to burning or melting of food. Additionally, aluminum can react with acidic or alkaline foods, potentially leaching aluminum into the food and causing health concerns such as neurological disorders and bone diseases. Moreover, aluminum coils can corrode over time, especially when exposed to moisture or certain chemicals, which can weaken their structure and pose a risk of breakage or injury. It's important to use aluminum coils appropriately and to monitor their condition regularly to minimize these risks.</p>

- Q: How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q: What are the different coil pattern options for aluminum coils?

- The different coil pattern options for aluminum coils include flat, stucco, diamond, and tread patterns.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for HVAC ductwork. It offers excellent heat transfer properties and is commonly used in both residential and commercial HVAC systems.

- Q: Can aluminum coils be used in food packaging?

- Yes, aluminum coils can be used in food packaging. Aluminum is a safe and versatile material that has been widely used in the food packaging industry for many years. It offers various benefits such as being lightweight, resistant to corrosion, and having excellent thermal conductivity. These properties make it ideal for food packaging applications where it is important to preserve the quality, freshness, and safety of the food products. Aluminum coils can be easily formed into different shapes and sizes, allowing for customized packaging solutions. Additionally, aluminum is a sustainable material as it is 100% recyclable, which further enhances its appeal for food packaging.

Send your message to us

Mill Finished Aluminum Coil Plate for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords