Mill Finish Cost Price Aluminum Kick Plate Coil 1 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

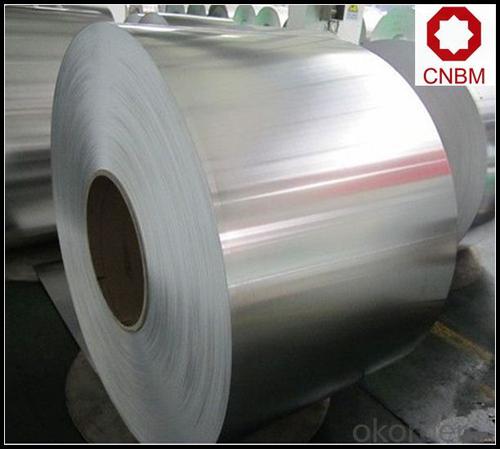

1. Specification of Mill Finish Cost Price Aluminum Coil

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Mill Finish Cost Price Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Cost Price Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

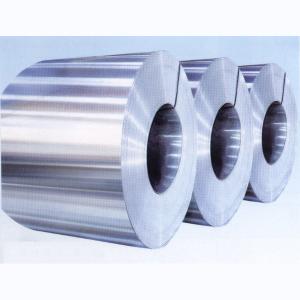

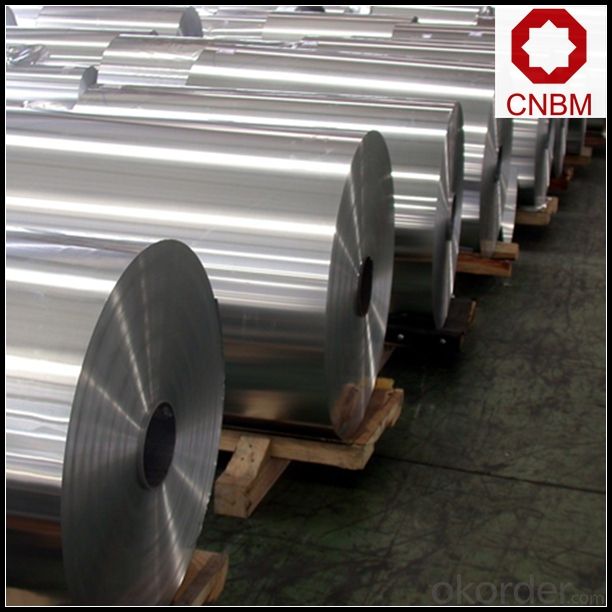

5. Image of Mill Finish Cost Price Aluminum Coil

6. Package and shipping of Mill Finish Cost Price Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: To put aluminum heads on my car do i have to add other things or basically can i just get them and put them on

- Aluminum heads will warp the first time the engine accidentally overheats. Why would you go with aluminum?

- Q: Can aluminum coils be used for window frames?

- Yes, aluminum coils can be used for window frames. Aluminum is a popular choice for window frames due to its lightweight, durable, and corrosion-resistant properties. It is also easily customizable and can be painted or anodized to achieve different aesthetics.

- Q: Can aluminum coils be painted for custom designs?

- Yes, aluminum coils can be painted for custom designs. Painting aluminum coils allows for endless possibilities in terms of customization and aesthetics. The coils can be painted with various colors, patterns, and designs to suit individual preferences and requirements. The paint application process involves cleaning the surface, applying a primer, and then applying the desired paint or coating. By painting aluminum coils, it is possible to create unique and eye-catching custom designs for a range of applications, including architectural elements, signage, automotive parts, and more. Additionally, the paint helps protect the aluminum from corrosion and enhances its durability.

- Q: I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- What is your machine that you will be using? Can you weld AC on it? Do you have a High Freq. Box? Will you GTAW it or use GMAW? What Alloy of Aluminum is it? Need much more info than you have provided. If GMAW best to have a pull or a push / pull wire feed system such as in a spool gun. Aluminum is too soft to just push from a wire feeder unit.

- Q: We have all heard the Us saying aluminum and their euro counterparts saying aluminium. I assumed this was just a small difference in culture or location. But, while reading my chemistry book (Chemistry the Central Science 12th) i came across a section saying: Cations formed from nonmetal atoms have names that end in -ium: NH4+ ammonIUM ion, H3O+ hydronIUM ion. So, i have came up with a hypothesis, could it be possible that when the periodic table was coming together, the aluminium was changed to aluminum to allow the rules to work? Thus making aluminum the correct spelling? Give me your thoughts.

- www.okorder ... aluminum (n.) 1812, coined by English chemist Sir Humphry Davy (1778-1829), from alumina, name given 18c. to aluminum oxide, from Latin alumen alum (see alum). Davy originally called it alumium (1808), then amended this to aluminum, which remains the U.S. word, but British editors in 1812 further amended it to aluminium, the modern preferred British form, to better harmonize with other metallic element names (sodium, potassium, etc.).

- Q: Are aluminum coils suitable for air conditioning systems?

- Yes, aluminum coils are suitable for air conditioning systems. Aluminum coils are commonly used in air conditioning systems due to their many advantages. Firstly, aluminum is a lightweight material, making it easier to handle and transport during installation. This also reduces the overall weight of the unit, making it more energy-efficient. Furthermore, aluminum coils have excellent heat transfer properties, allowing for efficient cooling of the air. They provide enhanced thermal conductivity, which helps in transferring heat quickly and effectively. This results in better cooling performance and improved energy efficiency, reducing electricity consumption and saving costs in the long run. Aluminum coils also offer superior corrosion resistance compared to other materials like copper. This is important in air conditioning systems, as they are exposed to moisture and humidity. Aluminum coils can withstand these conditions without corroding or deteriorating, ensuring longer lifespan and reliable performance. Another advantage of aluminum coils is their affordability. Aluminum is a cost-effective material, making it a popular choice for air conditioning manufacturers. This affordability can translate to lower costs for consumers, making air conditioning systems more accessible and affordable. In conclusion, aluminum coils are suitable for air conditioning systems due to their lightweight, excellent heat transfer properties, corrosion resistance, and affordability. They provide efficient cooling, durability, and cost-effectiveness, making them a preferred choice for air conditioning units.

- Q: Yep a slogan...the element Aluminum

- Aluminum: Keeping stoners amazed for over 50 years!

- Q: This question asks for criteria or methods to determine if an aluminum coil is of high quality.

- <p>To identify a good quality aluminum coil, consider the following factors: purity indicated by the alloy number, surface finish which should be smooth and free from defects, thickness consistency, and mechanical properties such as tensile strength and elongation. Check for certifications or quality standards compliance. Look for uniform color and absence of oil stains or rust. The coil should have precise dimensions and be free from dents or scratches. Additionally, consider the supplier's reputation and customer reviews.</p>

- Q: How is Aluminum formed??Thanks!!

- okorder nice.

Send your message to us

Mill Finish Cost Price Aluminum Kick Plate Coil 1 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords