Aluminum Kick Plate Coil Price - Aluminium Hot Rolling Coil for Flat Cold Rolling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Hot Rolling Coil for Flat Cold Rolling

Alloy: 1050, 1060, 1100, 1200, 3003, 3004, 3105, 1235, 8011, 8079, 8006, 5005, 5052, 5754, 5083,etc

2) Temper: Free

3) Thickness: ≥3mm

4) Width: 900-2300mm

5) Weight: 7-8 tons per coil

6) Dimensions and weight can be produced according to clients' specifications.

7) Inner Diameter: 505mm, 605mm

8) Packing: Export standard, wooden pallet.

9) Delivery time: 10-20 days

10) Minimum order quantity:20 tons per size.

11) The term of payment: T/T, irrevocable L/C at sight.

12) Surface: Bright

13)Origin: China

2. Application of Aluminium Hot Rolling Coil for Flat Cold Rolling

Aluminium Hot Rolling Coil is raw material of subsequent production of sheet and coils.

3. Feature of Aluminium Hot Rolling Coil for Flat Cold Rolling

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

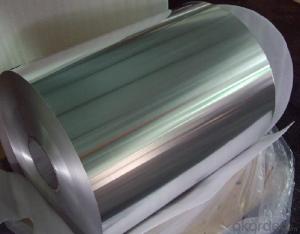

5. Image of Aluminium Hot Rolling Coil for Flat Cold Rolling

6. Package and shipping of Aluminium Hot Rolling Coil for Flat Cold Rolling

eye to sky

eye to wall

with wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How to deal with too much aluminum powder in aluminum striping?

- Currently, there are bag dust-removal system and water dust-removal system. The former is very popular with enterprises because of low maintenance cost, accounting for over 90%. But the problem is the dust accumulation because the ventilation and dust removal systems are not produced in strict accordance with the standard. For example, controlling wind speed does not meet the requirement; ventilation and dust removal system does not meet the requirements of explosion-proof, including the set of pipes, series and parallel connection, the choice of dust removal system, the spark detection and extinguishing measures.

- Q: How do you store aluminum coils to prevent damage?

- To store aluminum coils and prevent damage, there are several important steps you can follow. First, it is crucial to ensure that the storage area is clean, dry, and free from any moisture or humidity. This is because moisture can lead to corrosion and damage the aluminum coils over time. Second, you should store the coils in an upright position, preferably on pallets or racks, to prevent any bending or warping. By keeping them upright, you minimize the risk of coil deformation and maintain their shape for future use. Furthermore, it is advisable to cover the coils with a protective material such as plastic or tarp to shield them from dust, dirt, and other contaminants. This protective layer will also isolate the coils from any potential chemical exposure that could accelerate corrosion. Additionally, it is essential to handle the coils with care during storage, as rough handling or dropping them can lead to dents or scratches. To prevent any physical damage, use appropriate lifting equipment, such as forklifts or cranes, when moving or stacking the coils. Lastly, it is recommended to periodically inspect the coils during storage to ensure there are no signs of damage or corrosion. Regular visual checks will allow you to identify any issues early on and take necessary steps to prevent further damage. By following these storage practices, you can effectively prevent damage to aluminum coils, ensuring their longevity and preserving their quality for future use.

- Q: Can aluminum coils be used in pharmaceutical manufacturing?

- Yes, aluminum coils can be used in pharmaceutical manufacturing. Aluminum is a commonly used material in the pharmaceutical industry due to its excellent properties such as corrosion resistance, light weight, and ability to maintain product integrity. Aluminum coils are often utilized for packaging purposes, such as in blister packs, due to their suitability for protecting the medicine from moisture, light, and external contaminants.

- Q: Can aluminum coils be fabricated or formed into different shapes?

- Yes, aluminum coils can be fabricated or formed into different shapes. Aluminum is a malleable metal, which means it can be easily shaped and manipulated without cracking or breaking. Coil fabrication techniques such as bending, rolling, and stamping can be used to transform aluminum coils into various shapes and designs. These coils can then be further processed or assembled to create products with specific geometries, such as automobile parts, kitchen utensils, electrical components, or even architectural structures. The flexibility of aluminum as a material allows for a wide range of possibilities when it comes to shaping and forming it into different configurations.

- Q: Can aluminum coils be used in the production of solar reflectors?

- Certainly! Solar reflectors can utilize aluminum coils in their production. Due to its exceptional reflectivity and durability, aluminum is widely employed in the manufacturing of these reflectors. The coils can be manipulated and molded into the desired shape for the reflector, facilitating efficient sunlight reflection onto the solar panels. Furthermore, aluminum's lightweight nature simplifies its handling and installation in solar reflector systems.

- Q: This question asks about the suitability of aluminum coils for outdoor applications based on their weight and strength.

- <p>Yes, aluminum coils are lightweight and strong, making them suitable for outdoor use. Aluminum is known for its high strength-to-weight ratio, which means it can withstand significant stress without adding much weight. It also has excellent corrosion resistance, which is crucial for outdoor applications where exposure to weather elements can lead to degradation. Additionally, aluminum's malleability allows it to be easily shaped and formed into various configurations for different outdoor structures and applications. Its light weight also reduces the load on structures, which can be an advantage in many construction scenarios.</p>

- Q: so i have a dirtbike and i wanted to polish the swing arm.i have 100 grit,400,800 and 1200.i use to 100 to take off the coating the swing arm has and once its off its like a natural aluminum left.well i polished it before and it came out real good to a mirror finish.well i did the other half of the swing arm exactly the same even with new sand paper and it just didnt shine like the other half!i wet sanded it and i used car wax as my buffing compound,yes i used a soft buffing wheel.the car wax works really good!thats how i got the first half to a mirror shine but the other half just wasnt working for me.any suggestions?oh and i sanded in all one direction.

- Use 1200 to 2000 grit. Your sandpaper is way too course! The paper probably got gummed up With aluminum particals. Use water or oil to wash away particals. In other words wet sand it. Then get this polish called Mothers Aluminum Polish. And two micro fiber cloths. Use the mothers and wipe off with first towel. Then use second towel. Trust me! I spend alot of time in my machine shop making custom aluminum parts. If you can trickle water over the surface of what your polishing it helps. The 1200 to 2000 grit can be purchased at Walmart in the auto section.

- Q: A piece of aluminum foil 0.550 mm thick and 1.00 cm square is allowed to react with bromine to form aluminum bromide?a) How many mole of aluminum were used? ( The density of aluminum is 2.699 g/cm3.)I keep getting the same answer which I know is wrong. I used a formula to get the volume and then the mass to get the moles, but maybe this is wrong. Could someone explain the process. I got 4.32 x 10-1 mol Al, but the answer is 5.50 x 10-3 mol Al.

- 0.550mm = 0.055cm 0.055 x 1 x 1 = 0.055cc x 2.699g/cc = 0.1484g Al. Mol.mass = 27 g/mole 0.1484 ÷ 27 = 0.0055 moles. (5.5 x10-?)

- Q: Aluminum silicate felt fiber needle blanket noise reduction?

- And in the heat insulation, aluminum silicate needled blanket technology with a special one-time plastic molding, as the car chassis fireproof heat insulation layer, and now Xiamen Kinglong has reached a cooperation agreement.

- Q: im melting aluminum and what should i use for metal. cans will just oxygenize( i forget the word for it sorry)

- aluminum, in general, will just oxidize if heated in air. it is not just cans that behave that way when they (alcan, alcoa) smelt aluminum industrially they keep it in a reducing environment and do not allow molten aluminum to contact air. so use any aluminum you like but prevent it from contacting air.

Send your message to us

Aluminum Kick Plate Coil Price - Aluminium Hot Rolling Coil for Flat Cold Rolling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords