Ac Outdoor Unit Aluminum Coil Price - Aluminum Coils 1xxx D.C Mill Finished

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

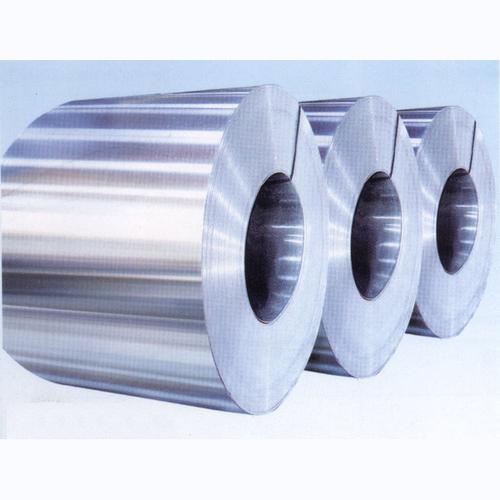

1.Structure of Aluminum Coils 1xxx D.C Mill Finished Description

Aluminum Coils 1xxx D.C Mill Finished has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Coils 1xxx D.C Mill Finished is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Coils 1xxx D.C Mill Finished

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminum Coils 1xxx D.C Mill Finished Images

4.Aluminum Coils 1xxx D.C Mill Finished Specification

| Alloy | AA1xxx (AA1050,AA1060,AA1070,AA1100 etc.) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Coils 1xxx D.C Mill Finished

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Coils 1xxx D.C Mill Finished products.

B.When will you deliver the products?

The Aluminum Coils 1xxx D.C Mill Finished will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum coils be used in pharmaceutical manufacturing?

- Pharmaceutical manufacturing can indeed utilize aluminum coils. In the pharmaceutical industry, aluminum is commonly employed for diverse tasks like packaging and manufacturing equipment. Aluminum coils are capable of producing containers, caps, and closures for pharmaceutical products. Particularly, these coils find extensive use in the manufacturing of blister packs, which are widely employed for packaging tablets and capsules. The preference for aluminum in pharmaceutical manufacturing is due to its exceptional barrier properties, resistance to corrosion, and capacity to safeguard the integrity of pharmaceutical products. Furthermore, aluminum possesses the advantages of being lightweight, recyclable, and having a low melting point, rendering it a versatile and cost-efficient option for pharmaceutical manufacturing.

- Q: This question asks whether aluminum coils are produced using recycled materials.

- <p>Yes, aluminum coils can be made from recycled materials. Recycling aluminum is a common practice because it conserves resources and energy. Recycled aluminum, also known as secondary aluminum, is processed from various waste materials such as used beverage cans, automotive parts, and construction materials. The recycling process involves melting the scrap aluminum, which requires significantly less energy compared to producing aluminum from raw materials. This makes the production of aluminum coils from recycled materials more sustainable and environmentally friendly.</p>

- Q: How are aluminum coils priced?

- Various factors contribute to the pricing of aluminum coils. These factors include the current market price of aluminum, the size and thickness of the coils, the quantity being purchased, and any additional customization or processing requirements. The market price of aluminum is influenced by factors such as supply and demand, global economic conditions, and trade policies. The cost of the coils can be influenced by their size and thickness, as larger or thicker coils typically require more raw materials and production time. The price may also be affected by the quantity being purchased, with larger orders potentially receiving volume discounts. Furthermore, any additional customization or processing, such as coating or shaping, can impact the overall price. In summary, the pricing of aluminum coils is a complex process that considers various factors relating to production costs and market conditions.

- Q: What are the advantages of using aluminum coils in various industries?

- There are several advantages of using aluminum coils in various industries. Firstly, aluminum is a lightweight material, which makes it easier to handle and transport. This also reduces the overall weight of products, leading to improved fuel efficiency. Secondly, aluminum coils have excellent corrosion resistance, making them ideal for applications in industries such as construction and automotive. Additionally, aluminum is a highly conductive material, enabling efficient heat transfer, which is beneficial in industries like HVAC and refrigeration. Lastly, aluminum is recyclable, contributing to sustainability efforts and reducing environmental impact. Overall, the use of aluminum coils offers numerous benefits in terms of weight, corrosion resistance, conductivity, and sustainability.

- Q: What are the maintenance requirements for aluminum coils?

- To ensure optimal performance and longevity, aluminum coils require regular cleaning and inspection. It is recommended to clean the coils at least once a year, or more frequently in areas with high pollution or corrosive environments. Use a mild detergent or coil cleaner along with a soft brush or cloth to remove any accumulated dirt, dust, or debris from the coils' surface. Regular inspection is also crucial to identify any signs of damage, corrosion, or leakage. Bent fins, dents, or corrosion should be promptly addressed to prevent further harm and maintain coil efficiency. If there are any indications of leakage, it is essential to have a professional technician inspect and repair the coils to prevent potential refrigerant leaks. Additionally, it is advisable to keep the area around the coils clean and free from obstructions that may hinder airflow, such as leaves, plants, or debris. This will ensure proper airflow and prevent the coils from overworking, which can result in inefficiency and possible damage. In conclusion, maintaining aluminum coils involves regular cleaning, inspection for damage, corrosion, or leakage, and keeping the surrounding area clear for optimal performance and longevity. By following these maintenance practices, you can ensure the efficient functioning of the aluminum coils and extend their lifespan.

- Q: How are aluminum coils used in the manufacturing of appliances?

- Aluminum coils are used in the manufacturing of appliances as a key component in the production of heat exchangers. These coils are utilized for their excellent thermal conductivity, which enables efficient heat transfer between the appliance and its surroundings. The coils are shaped into a specific design and then integrated into appliances such as refrigerators, air conditioners, and heating systems to facilitate the cooling or heating process.

- Q: What are the different color options available for aluminum coils?

- Aluminum coils offer a range of color options to choose from. Popular choices include white, black, gray, brown, and beige. These colors are obtained by applying a layer of paint to the aluminum coil using a technique known as coil coating. The paint used is of high quality and durability, ensuring resistance against fading, chipping, and cracking. Apart from these standard colors, there is also the option to customize the color according to individual preferences and design requirements. This customization is achieved through a color matching process, where a specific color is created for the project. The wide variety of color options available for aluminum coils ensures that there is a suitable choice for any residential, commercial, or industrial application.

- Q: Are aluminum coils suitable for food processing and packaging?

- Yes, aluminum coils are suitable for food processing and packaging. Aluminum is a versatile metal that offers numerous benefits for the food industry. Firstly, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during food processing and cooking. This property ensures that food is evenly cooked and prevents hot spots or uneven heating. Additionally, aluminum is a highly corrosion-resistant material, which is crucial for food packaging. It helps to protect the food from external factors such as moisture, oxygen, and light, which can degrade the quality and freshness of the product. Aluminum coils can be easily formed into various shapes and sizes, making them ideal for packaging different food products, including cans, pouches, trays, and lids. Furthermore, aluminum is a lightweight material, which makes it convenient for transportation and reduces energy consumption during distribution. It is also recyclable, meaning that it can be reused, reducing the environmental impact of food packaging. Overall, aluminum coils are well-suited for food processing and packaging due to their excellent thermal conductivity, corrosion resistance, versatility, lightweight nature, and recyclability.

- Q: When you open an aluminum beverage can, do particles of aluminum get into the drink?

- Most aluminum cans these days have a thin polymer coating inside that keeps the aluminum from being exposed to the (usually acidic) soft drinks. Aluminum also inevitably has a thin unreactive oxide layer on its surface. (This can be attacked by liquids, but they must be very acidic.) The only exposed aluminum surface when you open the can is around the hole created by the pull-tab. That has a very low surface area and is quickly coated with the unreactive oxide too. Aluminum content in the drink is consequently very low.

- Q: Can aluminum coils be painted?

- Indeed, it is possible to paint aluminum coils. By applying paint to aluminum coils, an extra layer of protection against corrosion can be achieved, along with an improvement in their aesthetic appearance. Nevertheless, it is crucial to properly prepare the surface prior to painting in order to ensure a strong adhesion and durability. This typically involves a thorough cleaning of the coils, the removal of any existing paint or coatings, and the application of a primer specifically designed for aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. For optimal and long-lasting results, it is advisable to use a high-quality paint specially formulated for metal surfaces. Additionally, following the instructions provided by the manufacturer and taking into account any environmental factors, such as temperature and humidity, that could impact the painting process, is of utmost importance.

Send your message to us

Ac Outdoor Unit Aluminum Coil Price - Aluminum Coils 1xxx D.C Mill Finished

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords