Mill Finish Aluminum Angle Strips for Heat Exchangers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Mill Finish Aluminum Strip For Heat Exchangers

Aluminum strip is widely used for manufacturing of various kinds of heat exchangers:

Air conditioning

Engine cooling

Condensers

Evaporators

Radiators

Heater cores

Charge air coolers/intercoolers

Engine oil coolers/transmission oil coolers

2. Feature of Mill Finish Aluminum Strip For Heat Exchangers

Core Alloy: 1060, 3003, etc

Cladding rate: 4%-18%

Thickness: 0.05-0.2mm

Width: 12-1250mm

Temper: HO, H14 etc

ID: 150mm, 200mm, 300mm, 400mm, 500mm

OD: 900-1450mmm

Other sizes is available according to custodsmer's request

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

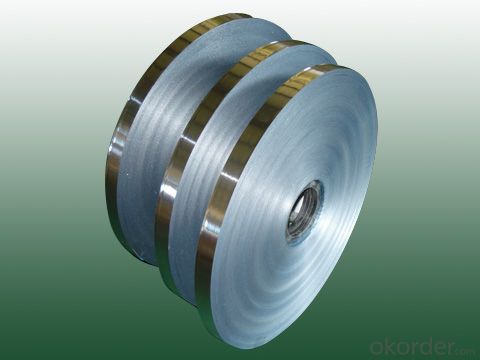

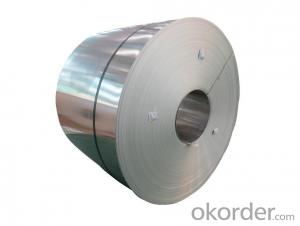

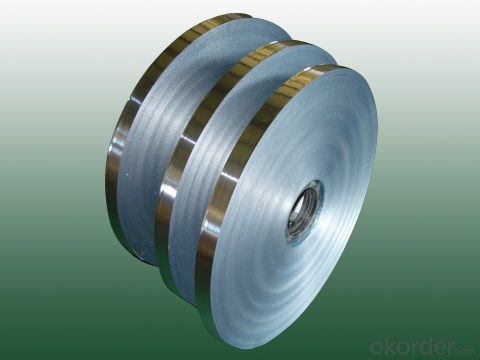

4. Image of Mill Finish Aluminum Strip For Heat Exchangers

5. Package and shipping of Mill Finish Aluminum Strip For Heat Exchangers

eye to Sky

eye to wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q: Explain the distinctions between aluminum foil and aluminum strips in a few sentences.

- <p>Aluminum foil and aluminum strips are both made from aluminum but differ in thickness and application. Aluminum foil is very thin, typically used for food packaging, cooking, and insulation due to its light weight and flexibility. It is also reflective, which makes it useful for cooking and baking. Aluminum strips, on the other hand, are thicker and more rigid, often used in construction, manufacturing, and automotive industries for structural support, heat exchangers, and electrical conductivity. They are not as flexible as foil and are not typically used for food-related applications.</p>

- Q: What are the various kinds of flooring options available that utilize aluminum strips in their construction?

- <p>Aluminum strip flooring comes in several types, each with unique characteristics. One common type is aluminum strip laminate flooring, which combines aluminum strips with a laminate surface for durability and style. Another is aluminum strip interlocking flooring, known for its easy installation and resistance to moisture. There's also aluminum strip parquet flooring, which mimics the look of wood parquet but with the benefits of aluminum. Lastly, aluminum strip modular flooring is popular for its versatility and ability to be easily replaced or reconfigured. Each type offers different benefits, such as resistance to wear, moisture, and heat, making them suitable for various environments, from residential to commercial settings.</p>

- Q: This question asks for an overview of the various types of aluminum strips that are available in the market.

- <p>Aluminum strips are available in various types based on their thickness, width, alloy composition, and surface finish. Common types include: 1) Plain aluminum strips, which are general-purpose and used in packaging and construction. 2) Embossed aluminum strips, used for decorative purposes or to enhance grip. 3) Anodized aluminum strips, which offer improved corrosion resistance and are used in automotive and aerospace applications. 4) Heat-treated aluminum strips, which have enhanced strength and are used in structural components. 5) Coated aluminum strips, which have a protective or decorative layer applied, used in food packaging and electronics. 6) Foil strips, which are very thin and used in food packaging, pharmaceuticals, and thermal insulation. Each type has specific applications and properties that make it suitable for particular industries and uses.</p>

- Q: Is there any health risk associated with the use of aluminum in food packaging?

- <p>There are some concerns about the use of aluminum in food packaging due to its potential to leach into food, especially when in contact with acidic foods. Aluminum exposure has been linked to neurological disorders, including Alzheimer's disease, although the evidence is not conclusive. The World Health Organization states that while there is no clear risk from dietary aluminum, further research is needed. It's important to note that aluminum is naturally present in many foods and drinking water, and the body can only absorb a small amount of aluminum from food packaging. Most aluminum exposure comes from natural sources, not from packaging.</p>

- Q: What are the regular maintenance concerns associated with aluminum siding on buildings?

- <p>Aluminum siding is generally low-maintenance, but there are a few issues that may require attention. These include checking for dents or damage caused by impacts, ensuring proper drainage to prevent water damage, and cleaning to remove dirt and grime that can dull the finish. Additionally, it's important to inspect for signs of corrosion, especially in coastal areas with high salt content, and to address any loose or peeling paint to prevent further damage. Regular inspection and minor repairs can help maintain the longevity and appearance of aluminum siding.</p>

- Q: This question asks for guidance on ensuring the correct installation and ongoing maintenance of an aluminum strip.

- <p>To ensure your aluminum strip is properly installed and maintained, follow these steps: First, ensure the surface where the strip will be installed is clean and free of debris. Use a high-quality adhesive that is compatible with aluminum for installation. Apply the adhesive evenly and press the strip firmly into place. Check for any gaps or misalignments and correct them immediately. For maintenance, regularly clean the strip to prevent dirt buildup. Avoid using harsh chemicals that could damage the aluminum. Inspect the strip periodically for signs of wear or damage and repair or replace as necessary. Proper installation and regular maintenance will extend the life of your aluminum strip and ensure its functionality.</p>

- Q: Is it possible to create a more energy-efficient roof using aluminum strips compared to other materials?

- <p>Yes, aluminum strips can be used to create a roof that is more energy-efficient than some other materials. Aluminum is a good conductor of heat, which can help in reflecting sunlight and reducing heat absorption, thus lowering cooling costs. Additionally, aluminum roofs can be designed with energy-efficient features such as solar reflectance and thermal emittance properties, which can further enhance their energy efficiency. However, it's important to consider the overall design, insulation, and installation quality to maximize energy efficiency.</p>

- Q: What types of aluminum strips are best suited for specific applications?

- <p>Yes, there are various types of aluminum strips tailored for specific purposes. For instance, 1100 series aluminum strips are known for their high ductility and are often used for deep drawing applications. 3003 series is popular for its corrosion resistance and is commonly used for chemical equipment and food processing. 5052 series offers good formability and is used in marine applications and aircraft structures. 6061 series is strong and often used in structural applications such as truck beds and window frames. Each type has distinct properties that make it suitable for different industries and applications.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a wall.

- <p>To install aluminum strips on a wall, first measure and mark the area where you want to install the strips. Clean the wall surface thoroughly to ensure proper adhesion. Apply a strong adhesive or use wall anchors and screws, depending on the weight and size of the strips. Align the first strip at the bottom and press firmly to secure it. Use a level to ensure it's straight. Attach subsequent strips side by side, maintaining a consistent gap if desired. Smooth out any bubbles or wrinkles with a putty knife. Once all strips are installed, allow the adhesive to cure according to the manufacturer's instructions before handling.</p>

- Q: What are the various color options for aluminum strips?

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include natural silver, which is the standard mill finish, black, white, and clear anodized for a protective and decorative finish. Other colors like gold, bronze, and various shades of blue, green, and red are also offered by some manufacturers. Custom colors can be achieved through anodizing or powder coating processes, allowing for a wide range of color options to meet specific design requirements.</p>

Send your message to us

Mill Finish Aluminum Angle Strips for Heat Exchangers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords