1 Inch Wide Aluminum Strips - 1060 O Aluminium Sheet and Coil with High Quality from EU Metal China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

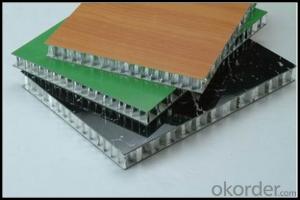

(1).Interior: wall cladding, sulfates, doors...

(2).Exterior: wall cladding, renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Aston Martin, Lotus, Jaguar or Audi are cocooned in an aluminium space frame made up of a combination of aluminium extrusions castings and sheet. Drivers’ safety is also likely to depend on extrusions such as, airbag deployment doors, side impact members and crash management systems.

Air-conditioning in cars has become standard nowadays. These are aluminium extrusions and drawn tubes which are now the norm for heat exchanger components.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

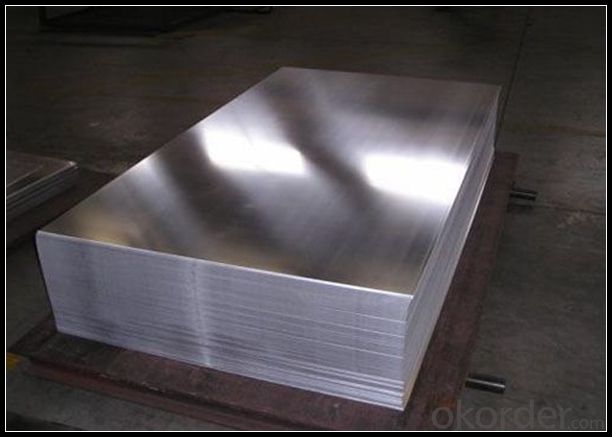

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for guidance on selecting a dependable supplier for aluminum strips, implying the need for criteria to evaluate supplier reliability.

- <p>To choose a reliable supplier of aluminum strips, consider the following: Check their reputation and industry experience. Ensure they have certifications for quality management systems like ISO 9001. Look at their product quality, consistency, and adherence to industry standards. Evaluate their delivery times and reliability. Assess their customer service and after-sales support. Investigate their financial stability to avoid potential risks. Request references from current or past clients to gauge their performance. Finally, consider the supplier's ability to scale up production to meet your growing needs.</p>

- Q: This question asks whether aluminum strips are suitable for use in cold weather conditions.

- <p>Aluminum strips are generally suitable for cold climates. Aluminum has a low coefficient of thermal expansion, which means it doesn't expand or contract significantly with temperature changes. This property makes it resistant to the effects of cold weather. Additionally, aluminum is lightweight, durable, and corrosion-resistant, which are desirable traits in materials used in cold environments. However, it's important to consider specific applications and the quality of the aluminum strip, as certain alloys or treatments may affect performance in extreme cold.</p>

- Q: This question asks for a comparison between aluminum strips and other common roofing materials, highlighting their distinct characteristics.

- <p>Aluminum strips are lightweight, corrosion-resistant, and have a long lifespan, making them ideal for roofing applications. They are also recyclable and can be easily bent and shaped. In contrast, other roofing materials like asphalt shingles are more affordable but have a shorter lifespan and are less eco-friendly. Metal roofing, similar to aluminum, is durable but can be heavier and more expensive. Clay and concrete tiles offer a traditional aesthetic but are heavy, require more maintenance, and are prone to breakage. Wood shakes and shingles are renewable but are less fire-resistant and have a shorter lifespan compared to aluminum.</p>

- Q: Is it possible to utilize aluminum strips for constructing a decorative railing system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a decorative railing system for your home or business. Aluminum is a popular choice due to its durability, low maintenance, and resistance to rust and corrosion. It can be easily shaped and painted to match the aesthetic of your property. Ensure that the railing meets local building codes and safety standards, and consider consulting with a professional to design and install the system for optimal safety and appearance.</p>

- Q: What types of aluminum alloys are known for their higher resistance to corrosion compared to other aluminum types?

- <p>Yes, certain types of aluminum alloys exhibit greater resistance to corrosion. These include 3003, 5052, and 5083 aluminum alloys, which contain magnesium and manganese, enhancing their corrosion resistance. Additionally, 6061 aluminum, which contains magnesium and silicon, is known for its good resistance to atmospheric corrosion. These alloys are often used in marine environments and other corrosive conditions due to their superior corrosion resistance.</p>

- Q: What kind of mask is good for welding aluminum strips?

- However, the overall quality of the active carbon mask is not high, carbon content, filtration efficiency is not up to standard. You can choose some professional brands to produce some products, to avoid these problems.

- Q: This question asks for the various factors that can influence the pricing of aluminum strips.

- <p>The price of aluminum strips is influenced by several factors, including the global supply and demand dynamics, the price of aluminum on the commodities market, production costs, transportation expenses, tariffs and trade policies, market competition, and economic conditions. Additionally, the quality and specifications of the aluminum strips, such as purity and thickness, can also affect pricing. Fluctuations in energy costs, especially for electricity used in the smelting process, can impact production costs and, consequently, the price of aluminum strips. Lastly, geopolitical events and environmental regulations can also have an indirect effect on the availability and cost of aluminum, thus influencing strip prices.</p>

- Q: This question asks for a method to accurately measure the length of aluminum strips.

- <p>To accurately measure the length of aluminum strips, use a digital caliper or a steel ruler with a high degree of precision. Place the strip on a flat surface and align the measuring tool with one end of the strip. Ensure the strip is straight and not bent. Gently extend the measuring tool along the strip until you reach the other end. Take note of the measurement displayed. For best accuracy, measure from the same point on both ends of the strip and repeat the process a few times to account for any potential parallax error. If the strip is very long, consider using a measuring tape with a fine scale. Always check your measuring tool for any wear or damage that could affect accuracy.</p>

- Q: The question asks if it's possible to use aluminum strips as flooring material in kitchen or bathroom areas.

- <p>Aluminum strips can be used for flooring in kitchens and bathrooms, but they are not the most common choice. They are known for their durability, resistance to moisture, and ease of cleaning, which are desirable traits for these areas. However, they can be slippery when wet, making them a less safe option for bathrooms. They also lack the warmth and comfort of other flooring materials, like tiles or wood. For kitchens, aluminum strips can be a good option for their low maintenance and resistance to spills, but they may not provide the aesthetic appeal that many homeowners desire. It's important to consider the specific needs and preferences of your space when choosing flooring materials.</p>

- Q: Is it possible to utilize recycled aluminum strips for construction purposes?

- <p>Yes, you can use recycled aluminum strips in your construction projects. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same strength and durability as new aluminum, making it suitable for various construction applications such as framing, roofing, and cladding. However, it's crucial to ensure that the recycled aluminum meets the required industry standards and specifications for your project to guarantee safety and performance. Always consult with a professional or engineer to confirm the suitability of recycled aluminum for your specific construction needs.</p>

Send your message to us

1 Inch Wide Aluminum Strips - 1060 O Aluminium Sheet and Coil with High Quality from EU Metal China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords