Aluminum Metal Strips for HVAC / Air Condition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminum strip is widely used in industry, such as packaging & building industry. Because the good anti heat and anti wet specification. it's very good for HVAC system / Air Condition materials. Normally it's outside bright and inside is matt.

2.Specification and Application

Specification

| Alloy | 1100/1060/1100/8011 |

| Temper | Soft |

| Process | CC |

| Thickness | 0.09~0.5mm |

| Width | As required |

| Core ID | As required |

Property

| Tensile strength | ≥90Mpa |

| Elongation | ≥10% |

| Tolerance of size | As GB Standard |

3. Advantages

We've been specialized in aluminium for more than ten years, we know this product very well, and we have good finacial support from government. And also flexible payment term and fast delivery.

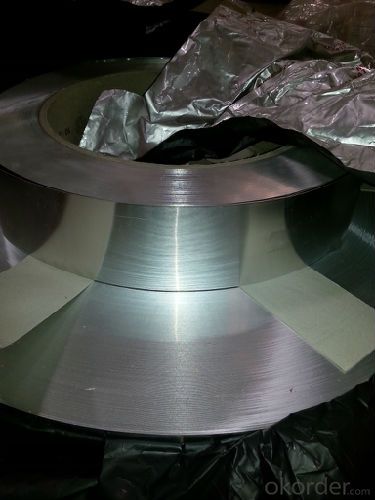

4. Pictures

5. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your minimum order quantity?

3tons per size.

- Q: What precautions should be taken into account when handling aluminum strips to ensure safety?

- <p>When using aluminum strips, safety concerns include avoiding skin contact with sharp edges to prevent cuts, ensuring proper ventilation to prevent inhalation of aluminum dust which can cause respiratory issues, and using protective eyewear to shield against flying debris. Additionally, it's crucial to handle aluminum strips carefully to prevent them from becoming projectiles, especially when cutting or bending. Always use appropriate tools designed for metal work and follow safety guidelines specific to the task at hand.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum strips in roofing systems.

- <p>Aluminum strips in roofing offer several advantages such as durability, resistance to corrosion and rust, lightweight nature, and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum strips can be easily recycled, contributing to environmental sustainability. However, there are downsides, including higher initial costs compared to other roofing materials and potential for denting if not properly installed or maintained. Aluminum can also be noisy during rain, and may require more frequent replacement due to its lighter gauge compared to some other materials.</p>

- Q: What benefits does aluminum provide compared to other metals when used for roofing applications?

- <p>Aluminum offers several advantages for roofing, including its lightweight nature, which reduces structural load. It is highly resistant to corrosion, making it suitable for various climates and environments. Aluminum's malleability allows for easy shaping and forming, enabling complex designs. It also has excellent reflectivity, which can help in reducing heat absorption and improving energy efficiency. Additionally, aluminum is recyclable and has a lower environmental impact compared to some other metals. These properties make aluminum a popular choice for roofing materials.</p>

- Q: Is it possible to construct awnings or shelters using aluminum strips?

- <p>Yes, you can use aluminum strips to make awnings or shelters. Aluminum is a popular choice due to its lightweight, corrosion resistance, and strength. It can be bent and shaped easily to create the desired structure. However, it's important to consider the thickness and grade of aluminum to ensure it can withstand the weight and environmental conditions it will be subjected to. Proper support and reinforcement should also be included in the design to maintain stability and durability.</p>

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: Does aluminum corrode in a manner similar to rusting?

- <p>Aluminum does not rust in the same way as iron or steel. Instead, aluminum reacts with oxygen in the air to form a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further corrosion, unlike rust which can compromise the integrity of iron and steel. While aluminum can tarnish or become discolored due to exposure to certain elements or chemicals, it does not rust in the traditional sense.</p>

- Q: This question asks for a step-by-step guide on how to install aluminum strip siding on a building.

- <p>To install aluminum strip siding, first, prepare the surface by cleaning and leveling the exterior walls. Measure and cut the siding strips to the required lengths. Apply construction adhesive to the back of the strips and press them onto the wall, starting from the bottom and working upwards. Use a nail gun to secure the strips, spacing nails evenly along the length. Overlap the strips by about 1/2 inch and trim the top edge to fit the eave or soffit. Apply caulk to seal any gaps and finish with a touch-up paint if necessary. Always follow the manufacturer's instructions for specific siding materials.</p>

- Q: What characteristics of aluminum strips make them an ideal material for roofing purposes?

- <p>Aluminum strips are suitable for roofing due to their lightweight nature, which reduces structural load. They offer excellent corrosion resistance, protecting against rust and decay, and are highly durable, maintaining their integrity for decades. Aluminum's malleability allows for easy shaping into various profiles, enhancing design flexibility. Additionally, aluminum strips reflect heat well, reducing energy consumption for cooling, and they are recyclable, contributing to environmental sustainability.</p>

- Q: This question asks if aluminum strips can be used as a substitute for conventional roofing materials in regions with cold weather conditions.

- <p>Yes, aluminum strips can be used to replace traditional roofing materials in cold climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand harsh weather conditions, including snow and ice. It is also low maintenance and has a long lifespan. However, it's important to consider thermal insulation properties, as aluminum is a poor insulator. Proper insulation and underlayment should be used to prevent heat loss and protect the structure from moisture. Additionally, ensure that the installation meets local building codes and consult with a professional to address any specific concerns related to cold climates.</p>

- Q: What types of aluminum strips are best suited for solar panel applications?

- <p>Yes, there are specific types of aluminum strips that are particularly suitable for use in solar panels. These include high-purity aluminum strips with low iron content, which are known for their excellent electrical conductivity and corrosion resistance. They are often used as busbars in solar cells to collect and transmit the generated electrical current. Additionally, aluminum strips with a high-strength alloy composition are used for structural support and frame components in solar panels due to their lightweight and durability. These aluminum strips are engineered to withstand harsh environmental conditions and maintain their integrity over the long lifespan of the solar panel.</p>

Send your message to us

Aluminum Metal Strips for HVAC / Air Condition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords