High-Quality Affordable Aluminum Angle Strips for Aluminum Composite Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

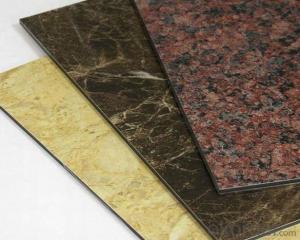

Aluminum composite panel

3005-H15 0.35mm*680mm ID:508mm

Application:

1, building external wall, curtain wall plate.

2, the old building exterior wall modification and retrofit.

Unit 3, balcony, equipment, interior compartments.

4, panels, logo plate, display platform.

5, the interior wall decoration panel, ceiling, advertising signs.

6, industrial materials, cold car body.

7, air conditioning, TV and other electrical appliances shell.Layer or acrylic coating

The upper and lower the minimum thickness of aluminum plate is not less than 0.50 mm, total thickness shall be not less than 4 mm.Aluminum material shall comply with the requirements of GB/T 3880, typically use the series of aluminum alloy plate, such as 3000, 5000, coating fluorocarbon resin coating should be adopted.

B. exterior wall decoration and advertising with aluminous model board

T-shirt bag | Width | 200-400mm |

Length | 300-600mm | |

Thickness of film | 0.01-0.05mm | |

Speed | 250-300pcs/min | |

Machine | Weight | 2600kg |

Power | 12.5kw | |

Air compression | 10hp | |

Dimensions | 7000x1600x1800mm |

PE primary use is in packaging (plastic bag,plastic films, geomembranes, containers including bottles, etc.). Many kinds of polyethylene are known, with most having the chemical formula.

.

- Q: What types of aluminum are more cost-effective for specific applications?

- <p>Yes, there are different types of aluminum alloys that offer varying degrees of cost-effectiveness depending on the application. For instance, 1100 series aluminum, which is 99% pure, is the most cost-effective due to its low alloying content but has limited strength. On the other hand, 6000 series alloys, like 6061, are stronger and more durable, making them ideal for structural applications but slightly more expensive. The choice depends on factors like strength, corrosion resistance, and weight requirements, which can influence the cost-effectiveness of an aluminum alloy for a specific use.</p>

- Q: What are the unique production techniques employed in the manufacturing of high-quality aluminum strips?

- <p>High-quality aluminum strips are produced using specialized manufacturing methods to ensure precision and consistency. Key methods include precision casting to achieve uniform thickness, continuous casting for improved material properties, and cold rolling to refine the strip's dimensions and surface finish. Annealing processes are also crucial for enhancing ductility and reducing hardness. Additionally, advanced surface treatments like anodizing or coating may be applied to improve corrosion resistance and aesthetics. Quality control measures such as strict dimensional checks and surface inspections are integral to ensuring the strips meet stringent quality standards.</p>

- Q: Is it possible to utilize aluminum strips in constructing a rainscreen wall system?

- <p>Yes, aluminum strips can be used to create a rainscreen wall system. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It allows for proper ventilation and drainage behind the cladding, which helps prevent moisture damage and thermal stress. When designing a rainscreen system with aluminum strips, ensure that the installation follows building codes and standards, and that the strips are properly spaced and sealed to maintain the system's effectiveness.</p>

- Q: This question asks for an overview of the various types of aluminum strips that are available in the market.

- <p>Aluminum strips are available in various types based on their thickness, width, alloy composition, and surface finish. Common types include: 1) Plain aluminum strips, which are general-purpose and used in packaging and construction. 2) Embossed aluminum strips, used for decorative purposes or to enhance grip. 3) Anodized aluminum strips, which offer improved corrosion resistance and are used in automotive and aerospace applications. 4) Heat-treated aluminum strips, which have enhanced strength and are used in structural components. 5) Coated aluminum strips, which have a protective or decorative layer applied, used in food packaging and electronics. 6) Foil strips, which are very thin and used in food packaging, pharmaceuticals, and thermal insulation. Each type has specific applications and properties that make it suitable for particular industries and uses.</p>

- Q: This question asks if it's possible to use various types of siding materials on a home's exterior to achieve a desired aesthetic.

- <p>Yes, you can use different types of siding on your home's exterior to match your style. Mixing materials such as vinyl, wood, brick, or stone can create a unique and personalized look. It's important to consider the architectural design and ensure that the materials complement each other in terms of color, texture, and style. Consult with a professional to help you choose the right combination that suits your home and preferences while also considering factors like durability, maintenance, and cost.</p>

- Q: Is it possible to utilize recycled aluminum in a project as an alternative to new raw materials?

- <p>Yes, you can use recycled aluminum in your project instead of new raw materials. Recycled aluminum is not only more environmentally friendly but also often more cost-effective. It requires significantly less energy to produce compared to new aluminum, reducing carbon emissions. Additionally, using recycled aluminum can help conserve natural resources and reduce waste in landfills. However, it's important to consider the quality and purity of the recycled material to ensure it meets the specifications required for your project.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: This question asks for a list of various types of aluminum strips that are specifically used for exterior applications.

- <p>Aluminum strips used for exterior applications come in various types, each serving specific purposes. These include: 1) Architectural Aluminum Strips, used for facades and building exteriors due to their durability and weather resistance. 2) Anodized Aluminum Strips, which offer enhanced corrosion resistance and a wide range of colors for aesthetic appeal. 3) Extruded Aluminum Strips, known for their strength and customizability, suitable for structural applications. 4) Embossed Aluminum Strips, which provide a textured surface for improved grip or decorative purposes. 5) Heat Insulating Aluminum Strips, used to reduce heat transfer in exterior applications. 6) Reflective Aluminum Strips, used for safety markings or to enhance visibility in outdoor settings. Each type is chosen based on the specific requirements of the project, such as strength, appearance, and environmental conditions.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof or wall.

- <p>To install aluminum strips on a roof or wall, follow these steps: 1. Measure and mark the area where the strips will be installed. 2. Clean the surface thoroughly to ensure proper adhesion. 3. Cut the aluminum strips to the required length using a hacksaw or tin snips. 4. Apply a bead of construction adhesive along the top edge of the strip. 5. Press the strip firmly into place, starting from one end and working your way along the surface. 6. Use a level to ensure the strip is straight and secure it with nails or screws at regular intervals. 7. Fill any gaps between the strips and the surface with caulk to create a watertight seal. 8. Finish with a coat of paint or sealant to match the surrounding area and protect the aluminum from weathering. Always follow the manufacturer's instructions for the specific adhesive and sealant products you are using.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

Send your message to us

High-Quality Affordable Aluminum Angle Strips for Aluminum Composite Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords