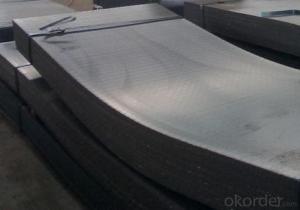

Mild Carbon Steel Sheets 20G CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 300 Series | Standard: | JIS, AISI, ASTM, DIN, EN | Length: | 1000-6000 |

| Thickness: | 0.5-100mm | Width: | 1000-2000 | ) | |

| Brand Name: | putan | Model Number: | Q235.Q345 | Type: | Plate |

| Application: | Construction plate,boiler plate,container plate,shipbuilding plate,all | Certification: | BV | type: | plate |

Packaging & Delivery

| Packaging Details: | Export standard package,bundled or be required. The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) 25tons about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) 25tons about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) 25tons about 68CBM |

| Delivery Detail: | 7-15 days after receiving the deposit |

Specifications

Q235 Carbon sheet

Original :China

thickness 0.5mm~100mm,

coil steel Processing.

MOQ : 25TON

Carbon Steel plate

Product | SS400 carbon steel plate price |

Standard |

GB/T700-2006,ASTMA283/A283M-03,ASTMA572/A572M,JISG3101-2004,SS400, JIS G3135-1986,SPEC590,EN10025/2-2004,S235JR or S235J2,E335 or S335JR…

|

Width | 500-2000mm |

WT | 0.5 –60mm |

length | 2000—6000mm |

Applications range |

Construction plate,boiler plate,container plate,shipbuilding plate,all kinds of industries and manufacturing structural applications.

|

MOQ | 25 ton / according to customers' requirement |

Quality | good attestation of honour choosed by customers SGS |

Supply capability | 5,000 ton / month |

Key to success | advanced technique and service and low price |

Authentification | ISO9001:2008 |

Market | North/South America, Europe, Asia,Africa,Mid East,ect. |

Packaging |

Standard seaworthy packing / according to the customers’requirement

|

Port | |

Delivery term |

T/T,L/C 30% deposit the balance before shipment,the balance paid by the copy of B/L OR L/C at sight

|

Delivery time | In 15 – 45 days after contract |

- Q: Can steel sheets be used for transportation applications?

- Yes, steel sheets can be used for transportation applications. Steel is a durable and strong material that can withstand the rigors of transportation, making it suitable for various applications such as automobile bodies, shipping containers, and railway carriages.

- Q: Can steel sheets be formed into curved shapes?

- Yes, steel sheets can be formed into curved shapes through a process known as cold forming or bending. Cold forming involves applying pressure to the steel sheet to reshape it without heating it. This process can be achieved through various methods such as roll forming, press braking, or stamping. The flexibility of steel allows it to be easily shaped into curves, making it a versatile material for various applications in industries such as construction, automotive, and aerospace.

- Q: What is the typical weight of steel sheets?

- The typical weight of steel sheets varies depending on their size, thickness, and type of steel being used. Generally, steel sheets can range in weight from a few pounds to several tons. For example, a standard 4x8 foot steel sheet with a thickness of 1/4 inch can weigh around 110 pounds, while a larger 10x10 foot sheet with a thickness of 1 inch can weigh over 1,000 pounds. It is important to note that these are just general estimates, and the weight can vary based on specific factors such as the alloy composition or any additional coatings applied to the steel sheets.

- Q: Can steel sheets be painted or coated?

- Yes, steel sheets can be painted or coated.

- Q: What are the different surface treatments for stainless steel sheets?

- Some of the different surface treatments for stainless steel sheets include brushing, mirror polishing, bead blasting, etching, and electroplating. Each treatment provides a different aesthetic appearance and can also enhance the corrosion resistance and durability of the stainless steel.

- Q: Can steel sheets be bent or folded?

- Yes, steel sheets can be bent or folded to a certain extent depending on their thickness and tensile strength.

- Q: Can steel sheets be used for mezzanine floors?

- Yes, steel sheets can be used for mezzanine floors. Steel is a commonly used material for constructing mezzanine floors due to its strength, durability, and ability to support heavy loads. Steel sheets can be used as the primary flooring material or as a subflooring layer, providing a stable and secure platform for various applications.

- Q: Are steel sheets suitable for oil rig platforms?

- Yes, steel sheets are suitable for oil rig platforms. Steel is widely used in the construction of oil rig platforms due to its exceptional strength and durability. Oil rig platforms are subjected to harsh environmental conditions, such as extreme temperatures, high winds, and corrosive saltwater, and steel has proven to be able to withstand these conditions effectively. Steel sheets provide a strong and stable foundation for the oil rig platforms, ensuring that they can support the weight of the rig, equipment, and personnel. The high strength of steel allows for the construction of large and complex structures while maintaining stability and safety. Furthermore, steel is highly resistant to corrosion, making it an ideal material for offshore applications. The oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. Steel sheets, however, can be specially treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is also a versatile material that can be easily shaped and fabricated into various components required for oil rig platforms. This flexibility allows for efficient and cost-effective construction processes, reducing both time and resources required for installation and maintenance. Overall, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

- Q: Can steel sheets be used for railway track components?

- Yes, steel sheets can be used for railway track components. Steel is a commonly used material in the construction of railway tracks due to its strength, durability, and resistance to wear and tear. Steel sheets can be used to manufacture various components of railway tracks, such as rails, sleepers, and fasteners, ensuring a reliable and long-lasting infrastructure for trains.

- Q: What is the cost of steel sheets compared to other metals?

- The cost of steel sheets can vary depending on various factors such as the type of steel, thickness, size, and market conditions. However, in general, steel sheets tend to be more affordable compared to other metals such as titanium or gold while still offering excellent strength and durability.

Send your message to us

Mild Carbon Steel Sheets 20G CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords