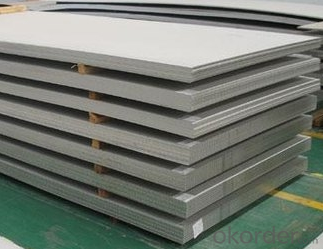

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, DIN, GB, JIS | Grade: | A572,A573,A633,A678,A709,A710,G3101,G3136,etc | Thickness: | 1mm-200mm |

| Brand Name: | SHOU GANG GROUP, AN STEEL | Model Number: | Q235 | ||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | widely | Special Use: | High-strength Steel Plate | Width: | 1000mm-3000mm |

| Length: | 1000mm-12000mm | Price Term: | FOB CIF CFR |

Packaging & Delivery

| Packaging Details: | standard seaworthy export packing or as the request of customers |

| Delivery Detail: | 10 days after deposit or according to customers' quantity |

Specifications

hot rolled carbon steel sheet

1.Thickness:1mm-200mm

2.Length:1000mm-12000mm

3.Width:1000mm-2000mm

hot rolled carbon steel sheet

| Product | HR steel plate prices carbon steel plate prices per kg |

| MOQ | 25 ton |

| Thickness | 1mm-200mm |

| Width | 1000mm-3000mm |

| Length | 1000mm-12000mm |

| Application | widely |

| Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

| Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

| Tpye | Steel plate |

| Surfacing | Coated |

| Productive Technology | Hot Rolled & Cold Rolled |

| Port | |

| Payment Terms | L/C,T/T,Western Union,MoneyGram |

| Product Ability | 5000 tons per month |

| Delivery | 10 days after deposit or according to customers' quantity |

| Packing | standard seaworthy export packing or as the request of customers |

- Q: Can steel sheets be used for making shipping containers?

- Yes, steel sheets can be used for making shipping containers. In fact, steel is the most commonly used material for constructing shipping containers due to its strength, durability, and resistance to various weather conditions and environmental factors. Steel sheets are typically cut, bent, and welded together to form the walls, roof, and floor of the container. This construction method ensures that the shipping container is sturdy and capable of withstanding the rigors of transportation, including stacking, lifting, and exposure to harsh marine environments. Additionally, steel containers are easily customizable and can be modified to meet specific requirements for cargo storage and transportation.

- Q: What are the different methods of cutting steel sheets?

- There are several different methods of cutting steel sheets, including traditional methods such as shearing, sawing, and plasma cutting, as well as more modern techniques such as laser cutting and waterjet cutting. Each method has its own advantages and limitations, and the choice of method depends on factors such as the thickness and type of steel, desired precision, and production volume.

- Q: Can steel sheets be used in high-temperature environments?

- Yes, steel sheets can be used in high-temperature environments. Steel is known for its high strength and resistance to heat, making it a suitable material for applications that involve elevated temperatures. However, the specific type of steel and its composition should be considered to ensure it can withstand the desired temperature range without excessive deformation or deterioration.

- Q: What are the advantages of using steel sheets in construction?

- There are several advantages of using steel sheets in construction. Firstly, steel sheets offer excellent strength and durability, making them ideal for supporting heavy loads and withstanding extreme weather conditions. Additionally, steel sheets are highly resistant to fire, corrosion, and pests, ensuring the longevity of the structure. Furthermore, steel sheets are flexible and can be easily customized and fabricated to fit various architectural designs. Lastly, steel sheets are eco-friendly as they can be recycled, reducing waste and promoting sustainability in the construction industry.

- Q: Can steel sheets be used in earthquake-resistant construction?

- Certainly, earthquake-resistant construction can utilize steel sheets. Steel, being a robust and durable material, has been extensively employed in seismic design and construction. As structural elements, steel sheets can function as beams, columns, and bracings, offering stability and strength to buildings. Steel possesses various properties that render it suitable for earthquake-resistant construction. Firstly, its flexibility and ductility allow it to deform without fracturing under seismic stress. This flexibility enables steel structures to absorb and dissipate seismic energy, thereby minimizing damage and reducing the impact on buildings. Additionally, steel boasts a high strength-to-weight ratio, meaning it can withstand considerable forces while remaining relatively lightweight. This feature is advantageous in earthquake-resistant construction as it reduces the overall weight of the structure, subsequently lessening the seismic forces exerted on the building. Moreover, steel is a homogeneous material, meaning it exhibits consistent properties and behavior throughout its structure. This characteristic facilitates accurate and predictable analysis and design of steel structures, ensuring their ability to withstand seismic forces. Furthermore, steel structures can be custom-designed and constructed with specific earthquake-resistant features, such as base isolation or energy dissipation devices, to further enhance their seismic performance. These features aid in absorbing and dissipating seismic energy, thereby minimizing the impact on the structure and enhancing its resistance to earthquakes. To conclude, steel sheets can indeed be utilized in earthquake-resistant construction. Their flexibility, strength, and capability to dissipate seismic energy make them an appropriate material for withstanding earthquake forces, ensuring the safety and stability of buildings in seismic regions.

- Q: What are the cost considerations for steel sheets?

- The cost considerations for steel sheets depend on various factors including the type and grade of steel, the size and thickness of the sheets, the quantity being purchased, and the current market conditions. Additionally, factors such as transportation costs, processing fees, and any additional customization or finishing requirements may also impact the overall cost of steel sheets.

- Q: Are steel sheets suitable for construction applications?

- Yes, steel sheets are highly suitable for construction applications. Steel is known for its strength, durability, and versatility, making it a popular choice in the construction industry. Steel sheets are commonly used in various applications, such as roofing, flooring, wall panels, structural frames, and cladding. They offer excellent load-bearing capacity, allowing for the construction of large and sturdy structures. Steel sheets are also fire-resistant, which enhances the safety of the building. Additionally, steel is resistant to pests, rot, and corrosion, ensuring a longer lifespan for the construction. Furthermore, steel sheets can be easily fabricated and customized to fit different construction needs, making them a cost-effective and efficient option. Overall, steel sheets are highly suitable for construction applications due to their strength, durability, versatility, and numerous other beneficial properties.

- Q: What is the average weight of a steel sheet per square foot?

- The weight of a steel sheet per square foot can change based on its thickness and the type of steel employed. Nevertheless, a typical weight range for a steel sheet per square foot falls between 40 and 70 pounds. It is crucial to understand that this is a rough approximation, and the actual weight may deviate due to specific factors like alloy composition and the manufacturing process.

- Q: What is the price range of steel sheets?

- The price range of steel sheets can vary depending on several factors such as the type and grade of steel, the thickness and size of the sheet, and the market conditions. Generally, the price range for steel sheets can range from around $0.60 to $1.50 per pound. However, it is essential to keep in mind that these prices are approximate and can change frequently due to fluctuations in the steel market and other economic factors. It is advisable to check with local suppliers or online platforms to get the most accurate and up-to-date pricing information for steel sheets.

- Q: Can the steel sheets be bent without cracking?

- Yes, steel sheets can be bent without cracking if the bending process is done within the material's acceptable limit of ductility and the correct bending techniques are used.

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords