Microporous Mineral Fiber Board: CE,ISO,SGS Certification Heat Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

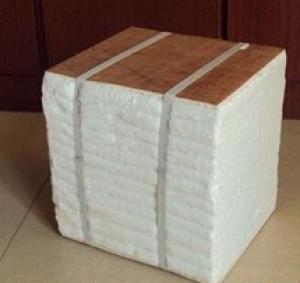

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

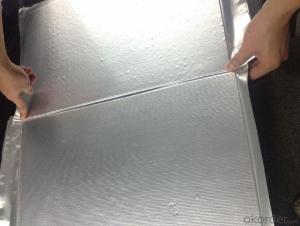

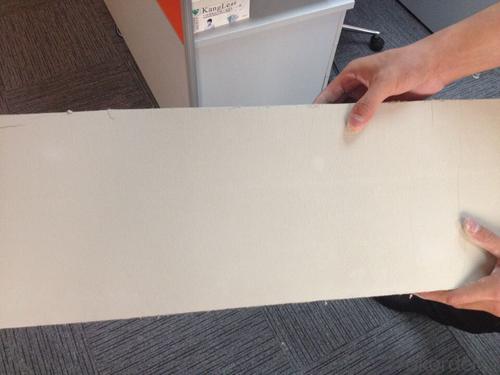

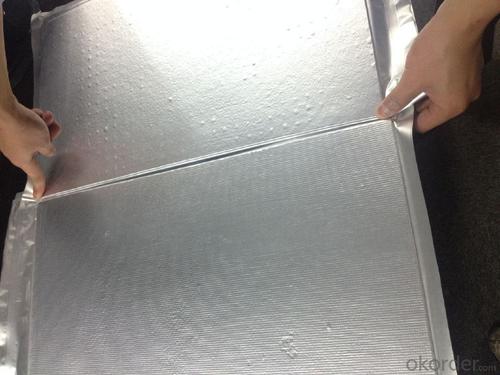

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab crack (crack was autoclaved late cooling stage, it refers to the irregular surface crack, calcium silicate board, or bright or dark is likely to cause fracture, calcium silicate board, low strength, appearance and performance is not up to the requirements)The main reason for the crack is to cool down too quickly.Solution: control the cooling rate, slow exhaust steam.The above is the calcium silicate board equipment in the production of prone to stick, blank, cracks and other phenomena of the reasons and solutions, if you encountered similar problems in production, you can have some reference.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles. Mineral wool board is mineral fiber cotton as raw material, the biggest characteristic is to have good sound absorption and heat insulation effect. Its surface has the effect of knurling and relief, such as star, caterpillar, cross flower, central flower, walnut line, stripe and so on. Mineral wool board can sound and heat insulation, fire prevention, any products do not contain asbestos, harmless to the human body, and has anti sag function.

- Q: What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Superfine glass wool insulation rockwool, steam pipe rubber board, aluminum silicate, calcium silicate products, such as polyurethane insulation form, in the application, to see the price, there are commonly used rock wool and polyurethane, rubber board, the price is relatively low, the thickness of rock wool 65, is the most thin.

- Q: What are the three major effects of fly ash in concrete?

- Fly ash "micro aggregate effect" in the fly ash particle size is very small beads and debris in cement can be the equivalent of unhydrated cement grains, tiny beads equivalent to nano material and lively, can significantly improve and enhance the structural strength of concrete and improve the homogeneity of products, and compactness.

- Q: What's the use of white portland cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: What are the raw materials of cement products? What's the function?

- Cement has a great influence on the properties of concrete. The kinds and quantities of cement containing minerals and the fineness of cement will affect the quality of cement products. The calcium silicate three in cement is an important factor in the coagulation of cement products. The reaction between three calcium silicate and water leads to the production of hydrated calcium silicate, and the hydrated calcium silicate gel acts as a cementing agent for aggregate and aggregate in concrete.

- Q: What are the main use of lime?

- A rigid inorganic cementitious material consisting mainly of calcium oxide. Lime is made from limestone, dolomite, chalk and shell with high content of calcium carbonate and calcined at 900~1100 DEG C. Lime is one of the earliest cementitious materials used in human life. Lime is widely used in civil engineering and can be used in medicine in our country.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- Mild steel is a type of carbon steel, and its carbon content is between 0.1% and 0.3%. The so-called carbon steel is also called carbon steel, refers to the carbon content of less than 2.11% of the iron carbon alloy. As we all know, the carbon content of the impact on the iron and carbon alloy is very large, the higher the content, the greater the hardness, but the smaller the toughness, and therefore easy to damage. Low carbon steel, because of its low carbon content, therefore, good toughness, low hardness, easy to carry out a variety of processing, such as welding, forging, etc.. And after some heat treatment, low carbon steel can obtain various properties, such as wear resistance, corrosion resistance and so on.

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: What is a building energy-saving materials?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

Send your message to us

Microporous Mineral Fiber Board: CE,ISO,SGS Certification Heat Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords