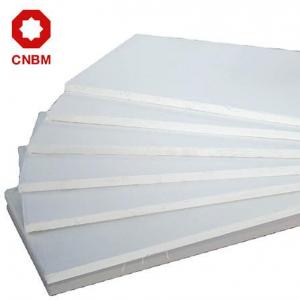

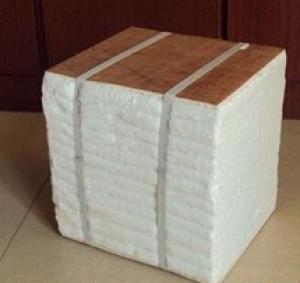

LG Calcium Silicate Board (1100 Degree)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m3 pc

- Supply Capability:

- 1000 per day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of LG Calcium Silicate Board (1100 Degree)

LG Calcium silicate board is an asbestos-free thermal insulation product that can withstand continuous operating temperature up to 1100. It is light weight, low thermal conductivity, high strength, easy to install, reliable and durable.

LG Calcium Silicate Board (1100 Degree) is commonly used as furnace backup insulation in cement, glass industry, steel, petrochemical, ceramic, and fire protection in building construction.

It not only increases production efficiency, but also provides energy saving and gives personnel protection in industrial safety aspect.

Feature of LG Calcium Silicate Board (1100 Degree)

High theral insulation value;

High strength;

Low bulk density;

Low thermal conductivity;

Easy to install;

Application of LG Calcium Silicate Board (1100 Degree)

Glass tank;

Shuttle kiln;

Tunnel kiln;

Annealing furnace;

Transfer ladle;

Rotary kiln;

Aluminum melting and holding furnace;

Heat processing equipments;

Other high temperature ovens;

Technical Data

- Q: What are the production methods of calcium silicate board material?

- Calcium silicate (microporous calcium silicate) material and calcium silicate board are produced by static steaming method, dynamic hydrothermal synthesis method and two reaction method.

- Q: What is the difference between calcium silicate board and cement fiber board?

- How to distinguish fiber cement, pressure plate and calcium silicate board?1, calculate density: calcium silicate board density is much lower than the fiber cement pressure plate, through the weight of the plate can calculate its approximate density.2, look at the color: Although there are manufacturers in order to pretend to be fiber cement pressure plate and deliberately add carbon black and so on, the board made dark, but not natural cement color.3, ask whether there are super thin plate and super thick plate, if not or can not do, it means that he is selling calcium silicate board or ordinary fiber cement, non pressure plate.4, if you go to the factory, you can visit its workshop, if there is steam pressure (commonly known as bullets), it is certainly calcium silicate board manufacturers, if there is no press, it is a common cement plant.

- Q: What's the difference between white carbon and carbon black? Can they be replaced?

- There are two kinds of substances. Some aspects can be substitutedCarbon black is the hydrocarbon gas in the process of strict control of incomplete combustion or pyrolysis of a black powder.

- Q: What are the high temperature resistant insulation materials at 400?

- According to the general rules of equipment and piping insulation, heat insulation material is a material with a thermal conductivity of less than 0.14W/ (m*K) when the average temperature is equal to or less than 623K (350 degrees Celsius). Heat insulation material is usually light, porous, porous, small thermal conductivity characteristics. Generally used to prevent heat loss of equipment and pipes, or frozen (also known as general cold) and low temperature (also known as cryogenic) use, so in our country, insulation materials, also known as insulation or cold preservation materials. At the same time, because of the porous and fibrous structure of thermal insulation material, it has good sound absorption function, so it is also widely used in the construction industry.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- Calcium silicate board is calcium silicate gypsum board, mainly with gypsum. At present, mainly 600*600MM, mostly used as large space, clear keel ceiling. But the family area is small, makes the Ming keel, the cost is high, also does not look well. This is why most families use a ceiling ceiling panels (gypsum board, calcium silicate board) ceiling.

- Q: What are the main use of lime?

- Lime milk and mortar, slaked lime or lime paste, with lots of paint. Lime mortar or slaked lime powder can be used to prepare lime mortar or cement lime mixture mortar for masonry or plastering engineering.

- Q: What is the main role of fly ash added in concrete products?

- Fly ash can inhibit the bleeding of fresh concreteFly ash can fine crumbs compensation in fine aggregate shortage, interrupt continuous bleeding mortar channels, and fly ash as cement replacement materials in the same consistency will make use of concrete water quantity is reduced in different degree, thus adding fly ash is beneficial to prevent the fresh concrete the bleeding.

- Q: How to make building glue?

- The invention relates to an architectural adhesive, which is characterized in that the composition of the building glue comprises 28-50wt% sodium silicate water solution, 34-53wt% quartz sand and 8-35wt% magnesium silicate.Adhesive for a building, it is the following: the weight ratio of 4 to 6, PVA cellulose 6 - 12, 1 - 2, copolymer admixture from 0.01 to 0.05, according to the proportion of polyvinyl alcohol with hot water first fully dissolved, then adding cellulose, copolymer, admixture and stir evenly. The glue can be combined with Portland cement or construction gypsum to cement all kinds of light plates. This product is non-toxic and tasteless, harmless to the human body, is a wide range of uses, superior technical performance of environmentally friendly building adhesive.

- Q: What is dew point of thermal insulation material?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Calcium silicate insulation insulation materials in 1980s has been recognized as the massive rigid insulation materials in one of the best, which is characterized by low density, high heat resistance, low thermal conductivity, flexural strength, high compressive strength, low shrinkage. But after entering 1990s, the promotion of the use of a downturn, the main reason is that many manufacturers to adopt in order to solve the problem of non asbestos fiber pulp, pulp fiber and not due to high temperature, thus affecting the thermal insulation material of high temperature resistance and increase the breaking rate, and not the economy.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 1995 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America Southeast Asia Western Europe Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, consultant,and training |

| Product Price Range | High;Average |

Send your message to us

LG Calcium Silicate Board (1100 Degree)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m3 pc

- Supply Capability:

- 1000 per day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords